A 3-phase separator is not just a piece of equipment; rather, it is the heart of many industrial processes. By efficiently separating oil, gas, and water, these separators serve as the unsung heroes working behind the scenes. As a result, they ensure that your operations run smoothly, safely, and economically.

Achieving an effective balance in separation is no easy task, but it is one that Red River has mastered. By carefully fine-tuning pressure levels and temperatures, our separators can efficiently parse out each phase. Consequently, this process ensures a level of purity that not only meets but also exceeds industry standards.

Gravity isn’t just a force; instead, it is our trusted ally. This natural principle plays a crucial role in achieving effective separation without excessive energy use. In turn, this aligns with our commitment to sustainability and efficiency while reducing operational costs.

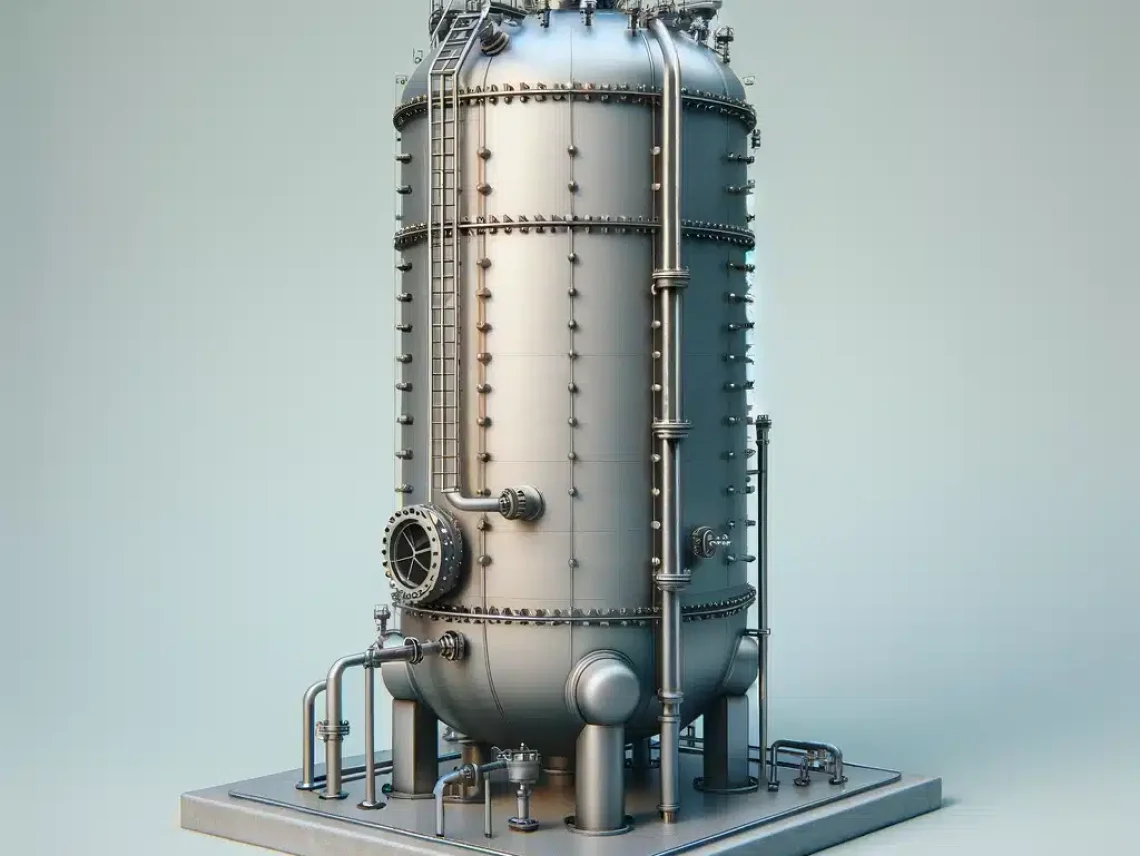

When deciding between horizontal and vertical configurations, several factors come into play. Your operational needs and space constraints are key considerations. At Red River, we help you navigate these choices so that the selected solution not only fits your current site but also supports your future growth.

Since every industry has its nuances, we take pride in designing solutions that effectively address these unique challenges. Whether it’s managing the high throughput of an oil refinery or maintaining the delicate balance required in biogas processing, we ensure that our separators perform reliably in demanding environments.

3-section separators play a crucial role in the oil and gas industry by separating crude oil, natural gas, and water. However, their applications extend to many other sectors. In the biogas industry, these separators help purify gas streams, ensuring efficient methane extraction from other gases and contaminants. Power plants use them to manage water and steam cycles, improving efficiency and reducing emissions. Additionally, in the mining sector, separators recover valuable minerals from slurry, showcasing their versatility across various industries.

Yes, high-performance 3-section separators effectively manage fluids with minimal density differences. Operators achieve this through enhanced gravitational settling, centrifugal forces, or a combination of advanced coalescing materials and precise temperature control. By fine-tuning stress and temperature parameters, even fluids with slight density variations can be efficiently separated.

The choice between horizontal and vertical separators depends on factors such as space availability, fluid characteristics, and separation performance needs. Horizontal separators work best for high gas-to-oil ratios, providing a larger interface for separation. They are also preferred in applications requiring significant liquid storage where space constraints are less of a concern. In contrast, vertical separators, with their smaller footprint, are ideal for well-streams containing more liquid, where gravitational settling alone ensures effective separation.

The destiny of three-section separation generation is poised for substantial improvements, particularly in the areas of automation, substances technological know-how, and environmental sustainability. Innovations in the sensor era and records analytics are anticipated to decorate the automation of separation techniques, taking into account real-time changes and progressed performance. New materials and coatings are being evolved to grow the durability and lifespan of separators, reducing renovation wishes and operational costs. Additionally, there may be developing attention on designing separators that reduce environmental effects, such as reducing electricity consumption and handling produced water in more sustainable ways.

Environmental rules play a giant role in the layout and operation of 3-phase separators, particularly regarding emissions, waste management, and water treatment. Regulators are increasingly specializing in reducing the environmental footprint of commercial operations, main to stricter necessities for emission controls and the treatment of separated water to prevent contamination. This has pushed innovations in separator layout to encompass capabilities that capture and deal with volatile natural compounds (VOCs) and other pollutants correctly. Additionally, water remedy technologies are being integrated into the separation process to make certain that water discharged or reused meets environmental standards, emphasizing the want for separators to now not only carry out successfully but also sustainably.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.