Understanding Pressure Vessel Failure

Table of Contents

ToggleIntroduction to the Pressure Vessel Failure

Pressure vessels are specialized bins engineered to save and ship gases or drinks under excessive pressure. Their feature is numerous, starting from storing compressed gases to facilitating chemical reactions and electricity generation procedures. These vessels come in various shapes and sizes, each tailor-made to particular industrial applications.

Importance in Various Industries

Across industries, pressure vessels play an essential position in ensuring the secure containment and transport of unstable materials. From powering cities to refining crude oil, these vessels are indispensable to the functioning of limitless industrial methods, making them critical property in cutting-edge financial systems.

Common Types of Pressure Vessels

Pressure vessels come in a myriad of paperwork, consisting of garage tanks, boilers, reactors, and warmth exchangers, each designed to satisfy specific operational necessities. Understanding the extraordinary styles of vessels is important for deciding on the maximum suitable option for specific packages.

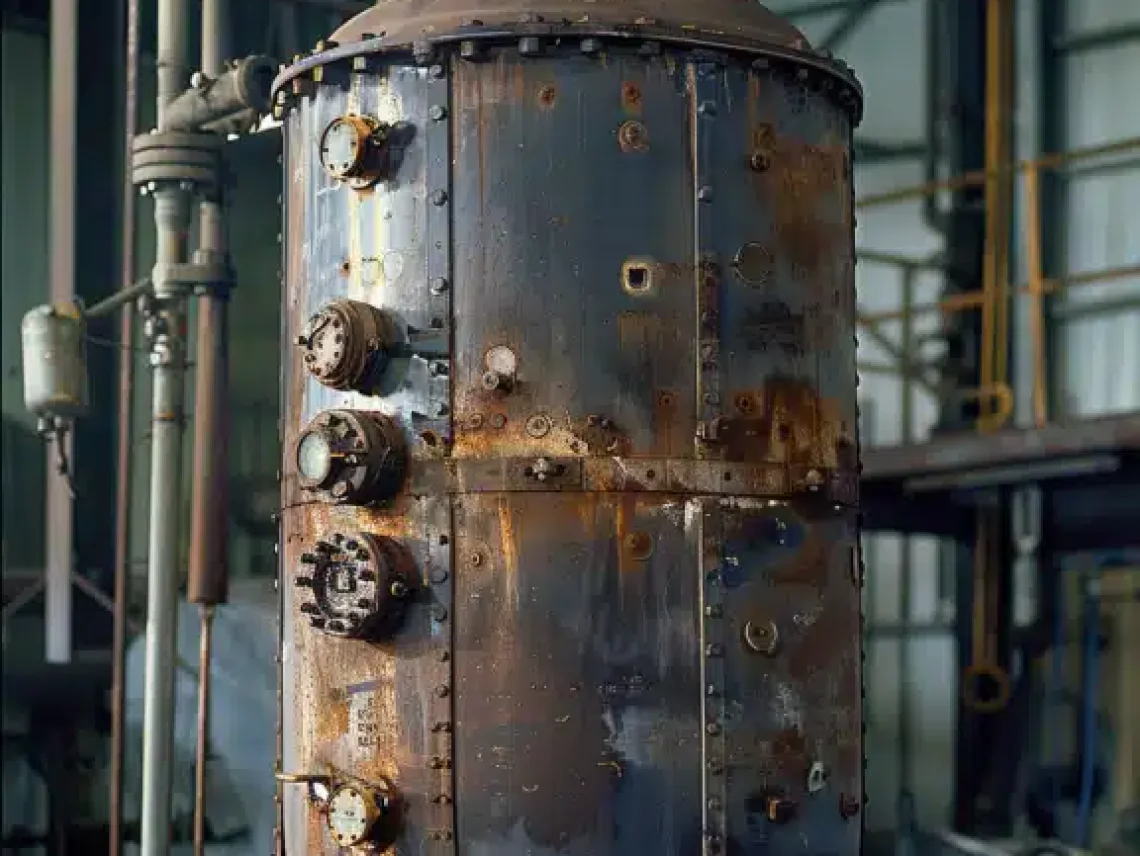

Overview of Pressure Vessel Failure

While pressure vessels are designed with robustness in mind, they could fail under certain conditions, posing enormous risks to protection and operations. Identifying the basic causes of those failures is important for preventing accidents and ensuring the reliability of pressure vessel systems.

Importance of Identifying Causes

Identifying the causes of pressure vessel failure is the first step in the direction of enforcing preventive measures. By understanding the underlying elements contributing to failure, operators can proactively deal with problems and mitigate risks, thereby safeguarding employees and belongings.

Impact on Safety and Operations

The consequences of pressure vessel failure may be extreme, ranging from environmental damage to lack of existence and belongings. Additionally, downtime due to vessel screw-ups can disrupt operations, main to economic losses and reputational damage for agencies. Prioritizing protection and reliability is paramount in mitigating these dangers.

Statistical Data on Pressure Vessel Failures

Statistical facts provide precious insights into the frequency and severity of pressure vessel disasters. By studying tendencies and patterns, industry stakeholders can become aware of areas for improvement and allocate resources effectively to decorate protection and operational efficiency.

Mechanical Causes of Pressure Vessel Failure

Fatigue Failure

Fatigue failure happens when pressure vessels enjoy repeated loading and unloading cycles, main to fabric degradation and eventual rupture. Factors inclusive of cyclic pressure, corrosion, and inadequate upkeep can accelerate fatigue failure.

Brittle Fracture

A brittle fracture happens all of a sudden and catastrophically below low temperatures or high-pressure situations. Poor fabric choice, design flaws, and insufficient insulation can growth the threat of brittle fracture in pressure vessels, highlighting the importance of sturdy design and cloth integrity.

Need a reliable partner?

FAQ’s

What are the most unusual symptoms of pressure vessel failure?

Common symptoms of pressure vessel failure include leaks, uncommon noises, sudden drops in pressure, visible deformities or cracks, and extraordinary temperature fluctuations. Regular inspection and tracking can help come across these warning signs and symptoms early, making an allowance for timely intervention and preventive protection to mitigate the danger of catastrophic failure.

How can I save you from pressure vessel failure in my facility?

Preventing pressure vessel failure requires a complete method that includes ordinary inspection, preservation, and adherence to enterprise great practices. Implementing a proactive upkeep program, engaging in ordinary integrity exams, monitoring operating conditions, and making sure compliance with applicable codes and standards are crucial steps in stopping failure and ensuring the lengthy-term reliability of pressure vessels.

What are the consequences of pressure vessel failure?

The outcomes of pressure vessel failure can be severe, ranging from belongings damage and environmental pollutants to injuries or fatalities. Additionally, downtime attributable to vessel failure can disrupt operations, leading to financial losses and reputational damage for groups.

How often must pressure vessels be inspected?

The frequency of pressure vessel inspections depends on various factors, consisting of vessel layout, running conditions, and regulatory necessities. In known, pressure vessels need to undergo regular inspections at predetermined periods, commonly ranging from month-to-month to yearly, with extra frequent inspections for excessive-chance packages or getting older gadgets.

What are some rising technologies for pressure vessel preservation and tracking?

Emerging technologies for pressure vessel upkeep and monitoring include superior non-unfavorable trying-out (NDT) strategies, together with phased array ultrasonics and virtual radiography, which provide more desirable detection abilities and stepped-forward inspection efficiency. Additionally, the use of predictive analytics, IoT sensors, and remote tracking systems allows actual-time condition tracking, permitting operators to discover abnormalities and ability failures before they arise.

Table of Contents

ToggleRelated Blog Post

- What are pressure related hazards?

- What type of hazard is high pressure?

- Which one is the hazards related to ship safety?

- What are the hazards of boiler and pressure vessel?

- What are the three main hazards of working with compressed air?

- What are three categories of dangers posed by high pressure systems?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.