How to Test Pressure Vessel Thickness: A Comprehensive Guide by Red River LLC

Table of Contents

ToggleMethods for Testing Pressure Vessel Thickness

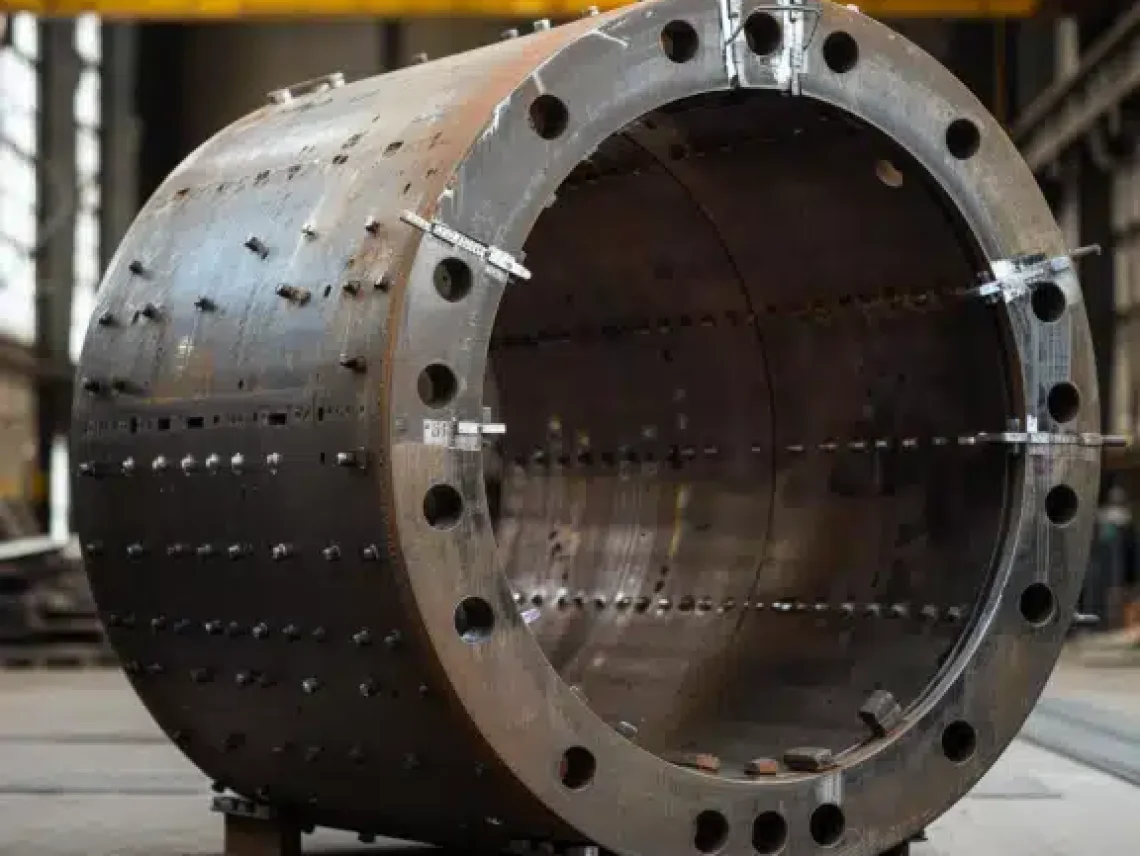

When it comes to making sure the integrity of pressure vessels, comparing thickness is paramount. At Red River LLC, we employ a whole lot of modern techniques to meticulously check pressure vessel thickness, safeguarding against potential risks and ensuring compliance with industry standards.

Surface Examination for Pressure Vessel Integrity

Visual indicators play an important position in the early detection of ability troubles. Our professional technicians behavior thorough surface examinations, meticulously inspecting pressure vessels for any signs and symptoms of deterioration or irregularities.

Ultrasonic Testing for Accurate Thickness Measurement

Harnessing the electricity of sound waves, ultrasonic testing affords specific measurements of pressure vessel thickness, both internally and externally. This method permits us to come across defects that might not be visible to the naked eye, ensuring comprehensive assessment and structural soundness.

Radiographic Inspection for Thorough Assessment

Utilizing penetrating radiation, radiographic inspection offers a detailed view of internal systems inside pressure vessels. This technique allows us to become aware of any hidden flaws or imperfections, ensuring thorough assessment and compliance with regulatory standards.

Equipment and Tools for Thickness Testing

Essential Tools and Instruments for Reliable Assessments

To ensure correct and dependable thickness exams, Red River LLC makes use of ultra-modern devices and instruments. From precision thickness gauges to superior imaging structures, our arsenal of equipment allows us to conduct thorough evaluations with the utmost precision and performance.

Interpretation of Thickness Test Results

Understanding Thickness Measurement Data for Informed Decision-Making

Once thickness checks are entire, deciphering the statistics appropriately is important for informed selection-making. At Red River LLC, our experienced technicians analyze thickness dimension facts meticulously, calculating final wall thickness and figuring out regions of challenge for timely intervention.

Maintenance and Monitoring

Implementing Proactive Maintenance Strategies for Long-Term Reliability

Beyond initial thickness testing, proactive preservation is vital for ensuring the long-term reliability of pressure vessels. Red River LLC assists clients in setting up regular inspection schedules and incorporating thickness trying out into protection programs, optimizing device lifespan, and minimizing downtime.

Benefits of Proper Thickness Testing

Enhancing Safety and Reliability Through Thorough Assessment

By prioritizing proper thickness trying out, Red River LLC allows customers to beautify safety and reliability, stopping catastrophic screw-ups and optimizing gadget lifespan. Our comprehensive checking-out methods provide peace of thought, minimizing dangers and maximizing operational efficiency for our valued customers.

Need a reliable partner?

FAQ’s

Why is it critical to check the thickness of pressure vessels?

Testing the thickness of pressure vessels is vital for ensuring structural integrity and safety. Over time, pressure vessels can experience corrosion, erosion, or other styles of degradation, main to capacity leaks or catastrophic disasters. Regular thickness testing allows for early detection of thinning walls, permitting proactive preservation and preventing luxurious downtime or injuries.

How regularly ought pressure vessel thickness checking out to be performed?

The frequency of pressure vessel thickness checking out depends on various factors, which include the vessel’s material, running situations, and regulatory necessities. In trendy, it is endorsed behavior thickness testing at least once every 12 months. However, vessels working in harsh environments or managing corrosive substances may additionally require more common trying out.

What are some unusual techniques used for testing pressure vessel thickness?

Several non-destructive testing (NDT) techniques are normally used to evaluate pressure vessel thickness, including ultrasonic testing, radiographic inspection, magnetic particle checking out, and liquid penetrant trying out. Each technique has its blessings and boundaries, and the choice of method relies upon factors which include vessel geometry, fabric composition, and accessibility.

Can pressure vessel thickness checking out come across inner defects?

Yes, pressure vessel thickness trying out can discover each inner and outside defect. Techniques such as ultrasonic trying out and radiographic inspection are mainly powerful at revealing inner flaws, consisting of corrosion, pitting, or weld defects. By using superior imaging technologies, inspectors can it should investigate the condition of a vessel’s partitions without the need for invasive methods.

What are the outcomes of neglecting pressure vessel thickness checking out?

Neglecting pressure vessel thickness checking out may have serious results, which include the threat of system failure, production downtime, environmental infection, and even injury or lack of existence. By proactively monitoring the thickness of pressure vessel partitions, agencies can perceive ability problems early on and take corrective movement to prevent accidents and make certain compliance with protection guidelines.

Table of Contents

ToggleRelated Blog Post

- What is the Barlow's formula?

- What is pressure vessel failure theory?

- What is the theory of pressure vessels?

- How do you calculate pressure vessels?

- What are the stresses in thick pressure vessels?

- What is the formula for the thin wall pressure vessel?

- What is the thinning allowance for pressure vessels?

- What is the minimum wall thickness for a pressure vessel?

- How do you calculate the thickness of a pressure vessel wall?

- When the diameter of pressure vessel is 15 times the wall thickness?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.