Pipe as Pressure Vessel: Classification and Considerations

Table of Contents

ToggleIntroduction to a pipe considered a pressure vessel

The world of pressurized systems is vast, encompassing a range of equipment from boilers to tanks. But what about pipes? Are they considered pressure vessels? This article delves into the nuances of this question, offering clarity on where pipes stand in the realm of pressure vessels.

What’s What in the World of Pressure

- Pressure Vessel: Think of these as the tough containers that keep gases or liquids from throwing a fit, holding them at pressures that aren’t down to chill with the vibe outside. These bad boys are all about handling the pressure, whether it’s coming from inside or getting thrown at them from outside, and they come in all sorts of shapes and sizes.

- Pipe: Pipes are like the highways for fluids, gases, or even the odd solid, helping them hitch a ride from Point A to Point B. These tubular heroes are the backbone of plumbing, oil and gas shenanigans, and a bunch of other gigs.

Pipes Getting Squeezed

- Under Pressure: Pipes often find themselves in the hot seat, moving stuff under pressure, especially when it’s gotta go up, up, up in skyscrapers or through the veins of industrial beasts.

- Carry vs. Hold: Even though pipes are all about carrying the load under pressure, their main gig is the journey, not just holding stuff in. This is where they tip their hats to pressure vessels, which are the kings and queens of containment.

Built Tough

- Choosing the Right Armor: Both pipes and their pressure vessel pals are designed with a keen eye on what pressures they’ll face, picking out the right materials and figuring out how thick their walls need to be.

- Safety Gear: Pressure vessels often come decked out with safety features like relief valves, but pipes? They’ve got their own set of tricks, especially at critical spots or if they’re part of a system that’s under pressure.

Rules of the Game

- Different Playbooks: Pipes and pressure vessels play by different rules. Vessels might stick to the ASME Boiler and Pressure Vessel Code, while pipes groove to the ASME B31 Code for Pressure Piping vibes.

- Check-ups: Both need regular health checks, but what you’re looking out for and how often can vary based on what they do and the dangers of their dance.

On the Job

Pipes and pressure vessels often work under similar conditions, especially in industries like oil and gas where they handle high-pressure flows. Here’s a deeper look at how they operate in these high-stakes environments:

- Where They Shine: In the oil and gas industry, pipes are subjected to immense pressure, often blurring the line between their function and that of pressure vessels. While pressure vessels are primarily designed to hold pressurized substances, pipes must handle these pressurized fluids as they flow through the system. This critical role requires them to withstand significant pressure while maintaining a steady flow.

- What They Worry About: For pressure vessels, maintaining structural integrity under high pressure is the primary concern. For pipes, it’s all about ensuring a smooth, steady flow. They’re engineered to handle pressurized environments while preventing leaks or bursts that could disrupt the entire system.

Bigger Picture

Pipes and pressure vessels are key players in many industrial applications, working together to support complex systems that ensure efficient operations.

- Teaming Up: Often, pipes and pressure vessels are part of an interconnected network, working side by side to manage and distribute pressurized substances. For example, in a heating system, a boiler (pressure vessel) works with a network of pipes to deliver heat throughout a facility, ensuring a steady flow while maintaining safety standards.

- Safe and Sound: The partnership between pipes and pressure vessels isn’t just about functionality; it’s also a matter of safety. When they operate together in a pressurized system, both components must be designed and maintained to prevent failures, ensuring that everything remains safe, secure, and operational.

The Evolution of Pipes

Pipes have come a long way from their early beginnings, evolving in both materials and functionality to meet the demands of modern industries.

- Way Back When: Pipes have been used for centuries, from ancient civilizations using clay or lead pipes to transport water, to today’s sophisticated metal and composite pipes capable of handling high pressures and corrosive substances. This journey reflects advancements in material science and engineering.

- Material Magic: Modern pipes are designed to be more robust, corrosion-resistant, and capable of withstanding higher pressures. The evolution of materials has enabled pipes to meet the rigorous demands of industries like oil and gas, where durability and safety are paramount.

Greening the Pipe Dream

With a growing emphasis on sustainability, pipes are now being designed to minimize their environmental impact without sacrificing performance.

- Eco-Friendly Designs: Modern pipes incorporate materials and designs that reduce environmental harm. Many are leak-proof and built to last, reducing waste and ensuring that fewer replacements are needed. The use of recyclable and durable materials contributes to greener industrial practices.

- Efficiency is Key: By making pipes more efficient at handling pressurized substances, industries can save on energy and resources. Efficient pipe systems require less maintenance and reduce the risk of leaks, benefiting both the environment and operational costs over the long term.

Money Matters

The financial aspect of using pipes in industrial applications is a significant consideration, from initial investments to ongoing maintenance costs.

- Investment: While pressure vessels typically represent a substantial investment due to their construction requirements, pipes, especially those designed for high-pressure applications, also come with notable costs. These investments are necessary to ensure reliable performance and longevity in industrial environments.

- Keeping Them Going: The lifespan of pipes, particularly those exposed to high pressures, depends on regular inspections, maintenance, and repair. Proper care not only extends their usability but also minimizes operational disruptions and potential hazards associated with leaks or failures.

Worldwide Wonders

- Common Language: While different places might have their own set of rules for pipes and pressure vessels, international standards like those from ISO help everyone get on the same page for global projects.

- Trade Talks: Pipes, especially the special kind for high-pressure gigs, are big players in global trade, highlighting their importance across industries.

Looking Ahead

- Smart Pipes: With the Internet of Things (IoT) getting bigger, future pipes might come with smart sensors to keep tabs on pressure, flow, and leaks on the fly.

- Change It Up: As the world changes, there’s a push for pipes that can flex with the times, adapting to new needs, pressures, and jobs.

Pipes, in their gig as the go-to transporters, are crucial, especially when they’re working under pressure. They might not always get the pressure vessel label, but their role in keeping things moving safely and efficiently is top-tier. As tech evolves and we get smarter about handling pressure, the journey of pipes is set to be one of constant innovation, safety, and efficiency.

Need a reliable partner?

FAQ: Understanding Pipes and Pressure Vessels

What distinguishes a pipe from a pressure vessel in terms of design and function?

Pipes and pressure vessels, while both integral in industrial applications, serve different purposes and are designed accordingly. Pipes are primarily designed for the transport of fluids (liquids and gases) from one location to another. Their design focuses on ensuring a smooth, efficient flow with minimal resistance. Pressure vessels, on the other hand, are designed to store fluids under pressure. They are constructed to withstand higher internal pressures and are subject to more stringent safety standards and regulations due to the potential risks involved.

Can a pipe system be classified as a pressure vessel under certain conditions?

Yes, a pipe system can be classified as a pressure vessel if it meets certain criteria. If a section of the piping system is used for storing fluids under pressure, rather than just conveying them, and if it includes features like closures, valves, and flanges that allow it to contain pressurized fluids, it may be considered a pressure vessel. The classification depends on the design, operating pressure, and the specific codes and standards applicable in the jurisdiction.

What are the key safety considerations for pipes used in high-pressure applications?

For pipes used in high-pressure applications, safety considerations include material selection, design pressure ratings, corrosion resistance, and regular maintenance and inspections. The material must be able to withstand the internal pressures and chemical properties of the fluid being transported. Additionally, the pipe should be designed with a pressure rating that exceeds the maximum operating pressure to provide a margin of safety. Regular inspections for signs of wear, corrosion, and damage are crucial to prevent leaks and failures.

How do regulations and standards for pressure vessels apply to pipes?

Regulations and standards for pressure vessels can apply to pipes if those pipes function as part of a pressure-containing system. Standards such as the ASME Boiler and Pressure Vessel Code in the United States provide guidelines for the design, fabrication, inspection, and testing of pressure vessels, and certain sections of this code may be relevant to pipes used in pressurized systems. Compliance with these standards ensures safety and reliability in high-pressure applications.

What advancements in pipe design contribute to their use in pressure vessel applications?

Advancements in pipe design that contribute to their use in pressure vessel applications include the development of high-strength materials, improved fabrication techniques, and enhanced inspection and testing methods. High-strength materials allow pipes to withstand greater pressures, while advanced fabrication techniques, such as precision welding and seamless construction, improve the integrity and reliability of the pipe. Non-destructive testing methods, like ultrasonic testing, ensure the detection of flaws and weaknesses without damaging the pipe, contributing to safer operation in pressure vessel applications.

Table of Contents

ToggleRelated Blog Post

- What is the difference between a pressure vessel and an expansion tank?

- What is the difference between cylinder and pressure vessel?

- Is a pressure vessel the same as a compressor?

- Why is a boiler called a pressure vessel?

- Why is pressure vessel used in pumps?

- Is a pipe considered a pressure vessel?

- Is a water boiler a pressure vessel?

- What is a pressure tank called?

- What is a pressure vessel UK?

Solutions

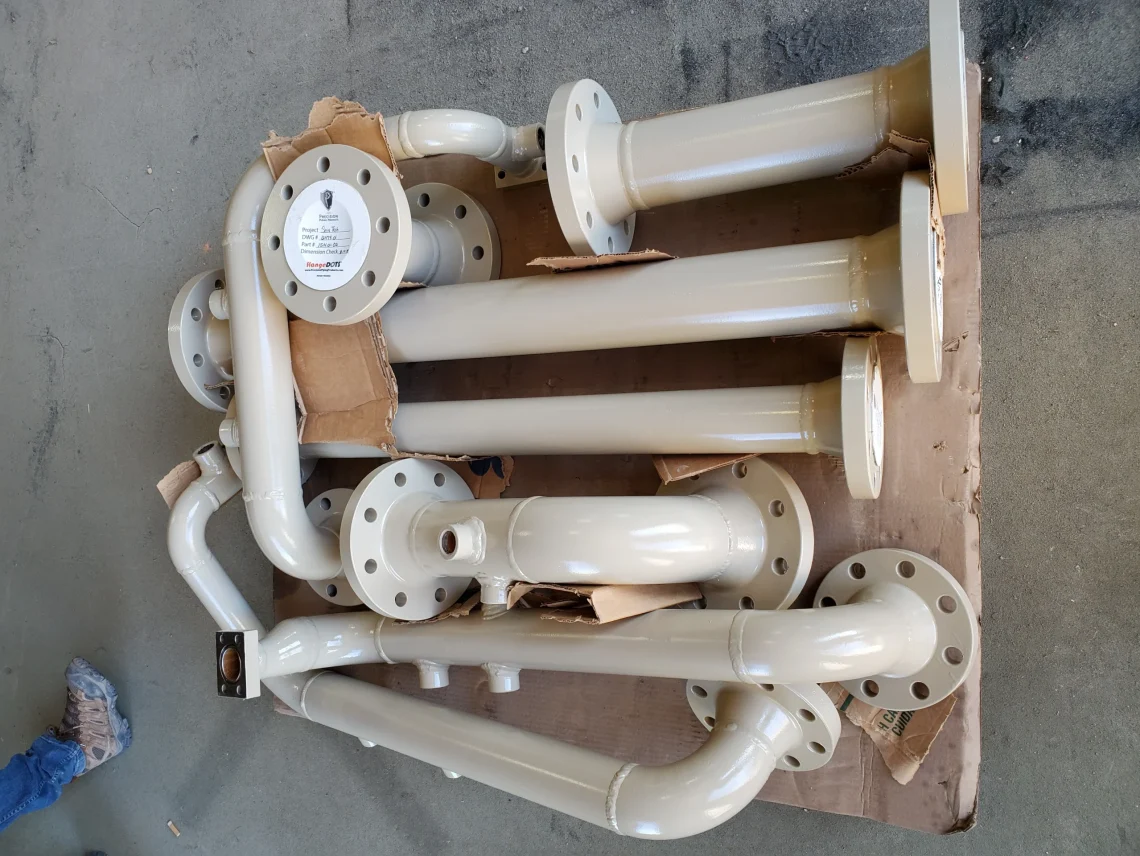

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.