Understanding Hydrogen Storage: Type 3 vs Type 4 Tanks

Table of Contents

ToggleIntroduction to the difference between Type 3 and Type 4 hydrogen tanks

Hydrogen fuel, with its high energy content and zero-emission profile, is pivotal in the shift towards a sustainable energy landscape. It’s not just an alternative fuel; it’s a symbol of progress, powering everything from daily commutes to large-scale industrial processes. At Red River, we’re committed to facilitating this shift, providing hydrogen storage solutions that are as innovative as they are reliable.

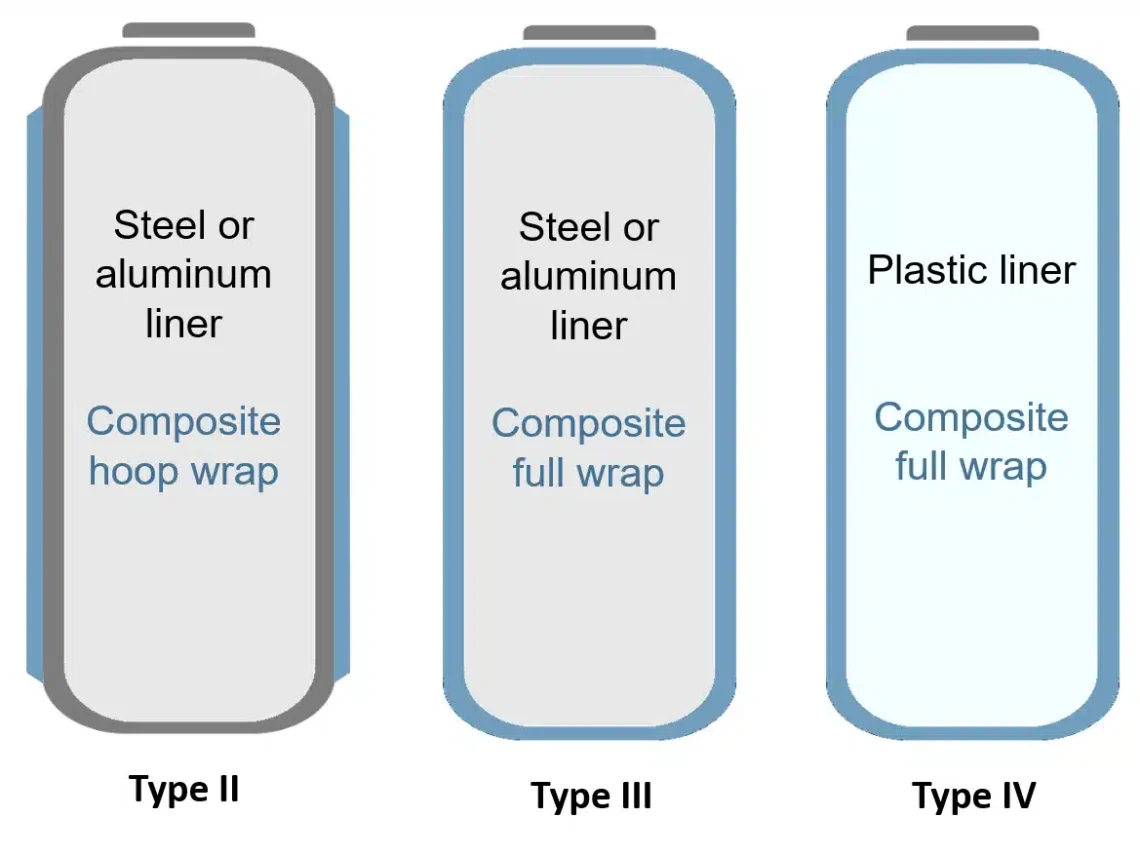

Overview of Hydrogen Storage Tank Types

Navigating the world of hydrogen tanks can be complex, but it’s crucial to understand the nuances between the different types. Type 3 and Type 4 hydrogen tanks are at the cutting edge of this technology, each with unique attributes suited to various applications. Whether it’s the advanced composite materials of Type 4 or the robust metallic liners of Type 3, we at Red River have the expertise to guide you through the specifics, ensuring you make an informed decision that aligns with your project’s needs.

Importance of Choosing the Right Hydrogen Tank

Selecting the appropriate hydrogen storage tank is not just a matter of compliance or capacity; it’s about aligning with a partner who understands the intricacies of your industry and shares your commitment to excellence and safety. At Red River, we don’t just manufacture tanks; we engineer solutions that embody American values—morals, family, work ethic, and the relentless pursuit of happiness. When you choose a Type 3 or Type 4 tank from us, you’re not just investing in a product; you’re embracing a partnership with a team that stands firm on the principles of quality, safety, and integrity.

The Basics of Hydrogen Tanks

What Are Hydrogen Tanks?

Hydrogen tanks are the backbone of hydrogen fuel storage, designed to securely contain hydrogen gas at high pressures. They are pivotal in various sectors, from automotive to aerospace, where the efficient storage of hydrogen as a clean energy source is crucial.

Materials Used in Hydrogen Tank Construction

The construction of hydrogen tanks requires materials that can withstand high pressures while maintaining integrity. Type 3 tanks utilize an aluminum liner wrapped in carbon fiber, whereas Type 4 tanks are made with a lighter-weight plastic liner and carbon fiber exterior.

Safety Standards for Hydrogen Tanks

Safety is paramount in hydrogen tank design. Rigorous standards ensure that tanks can handle the stresses of use. Both Type 3 and Type 4 tanks adhere to stringent protocols, including those set by the American Society of Mechanical Engineers (ASME).

Exploring Type 3 Hydrogen Tanks

Composition and Structure of Type 3 Tanks

Type 3 hydrogen tanks feature a sophisticated construction that combines a durable aluminum alloy core with an outer layer of high-strength carbon fiber. This design allows Type 3 tanks to handle high internal pressures, making them exceptionally resilient against external impacts and stresses. The aluminum core provides structural integrity, while the carbon fiber wrapping enhances strength and pressure resistance, ensuring safe hydrogen storage in demanding applications.

Benefits of Using Type 3 Hydrogen Tanks

Type 3 tanks are popular for their durability and cost-effectiveness. They offer an optimal balance of strength and affordability, making them an ideal choice for applications that require reliable yet economically viable hydrogen storage solutions. Their robustness extends their service life, reducing maintenance costs, while their pressure tolerance makes them versatile for various storage and transport needs.

Common Applications for Type 3 Tanks

Due to their resilient construction, Type 3 hydrogen tanks are widely used in commercial vehicles, refueling stations, and backup power systems. Their reliability and pressure resistance make them a go-to choice for hydrogen-fueled buses, trucks, and other heavy-duty vehicles. Additionally, refueling stations depend on Type 3 tanks to safely store and dispense hydrogen, while backup power systems utilize them to maintain operational reliability during power outages.

Delving into Type 4 Hydrogen Tanks

The Innovative Design of Type 4 Tanks

Type 4 hydrogen tanks feature an advanced design, utilizing a non-metallic liner, typically made from high-density polymers, paired with a carbon fiber composite wrapping. This construction eliminates the need for a metallic core, resulting in a tank that is significantly lighter and more compact. The design’s innovation lies in its ability to safely store hydrogen at high pressures while maximizing storage capacity and minimizing weight.

Advantages of Type 4 Tanks Over Other Types

One of the most significant advantages of Type 4 tanks is their lightweight construction. This translates to improved fuel efficiency and extended range for vehicles, as the reduction in tank weight allows for more hydrogen storage without adding extra load. This makes Type 4 tanks highly suitable for applications where weight and energy efficiency are critical, such as in electric-hydrogen hybrid vehicles and aviation.

Industrial Uses of Type 4 Hydrogen Tanks

Type 4 tanks are especially advantageous in high-demand sectors like public transportation and logistics, where weight savings and capacity are crucial. Their lightweight and high-capacity design make them suitable for hydrogen-powered buses, trains, and even ships, where they contribute to enhanced fuel economy and longer operational ranges. Additionally, Type 4 tanks are finding their way into innovative applications in logistics and heavy industries, where hydrogen serves as a clean energy alternative to traditional fuels.

Comparative Analysis: Type 3 vs Type 4 Tanks

Material Differences and Their Impact on Performance

The choice between Type 3 and Type 4 tanks often comes down to a balance between weight, capacity, and cost, with each material offering distinct advantages.

Durability and Longevity: Type 3 vs Type 4

Type 3 tanks are lauded for their longevity, while Type 4 tanks are celebrated for their innovative, lightweight design that does not compromise on strength.

Cost-Benefit Analysis of Type 3 and Type 4 Tanks

Investing in the right type of hydrogen tank involves analyzing the long-term cost savings in operation and maintenance, with Type 4 tanks often providing a higher return on investment in scenarios where weight and efficiency are critical.

Manufacturing Process of Hydrogen Tanks

How Type 3 Tanks are Made

Type 3 hydrogen tanks begin with an aluminum liner. This liner is precision-shaped and then wrapped with high-strength carbon fiber and resin to withstand the high pressures required for hydrogen storage. The meticulous process ensures durability and safety, with each layer scrutinized for perfection.

The Production of Type 4 Tanks

The production of Type 4 tanks is a testament to innovation, utilizing a lightweight polymer liner and a carbon fiber composite wrap. This combination not only reduces weight but also increases the tank’s capacity, making it a revolutionary step in hydrogen storage technology.

Quality Control in Hydrogen Tank Fabrication

At Red River LLC, quality control is not a checkpoint but a continuous process. From the raw materials to the final product, every tank is subject to rigorous testing and inspection to ensure it meets our high standards and those of the industry.

Safety Protocols for Hydrogen Tanks

Regulatory Standards for Tank Safety

Our hydrogen tanks are designed and manufactured in compliance with the most stringent regulatory standards, including those set by the ASME and the Department of Transportation.

Safety Features of Type 3 Tanks

Type 3 tanks are equipped with numerous safety features, including pressure relief devices and robust carbon fiber wraps that provide an extra layer of protection against impacts and punctures.

Enhanced Safety Measures in Type 4 Tanks

Type 4 tanks take safety further with their non-metallic liners, which are less prone to corrosion and thus offer an additional safety margin in hydrogen storage.

The Environmental Impact of Hydrogen Tanks

Eco-Friendliness of Type 3 and Type 4 Tanks

Both Type 3 and Type 4 tanks are engineered with the environment in mind, designed for longevity and recyclability to minimize their ecological footprint.

Life Cycle Assessment of Hydrogen Tanks

Life cycle assessments of our tanks ensure that from production to disposal, the environmental impact is kept to a minimum, supporting the sustainability goals of our clients.

Recycling and Disposal of Old Hydrogen Tanks

We’re committed to the responsible recycling and disposal of hydrogen tanks, offering guidance and services to ensure that end-of-life tanks are treated with environmental stewardship.

Future of Hydrogen Storage Technology

Innovations in Hydrogen Tank Design

Red River LLC is at the forefront of hydrogen tank design, constantly seeking out and implementing innovations that increase efficiency, reduce weight, and enhance safety.

The Potential of Type 3 and Type 4 Tanks in Renewable Energy

Our Type 3 and Type 4 tanks are integral to the renewable energy sector, offering scalable and flexible storage solutions that are essential for the growth of this vital industry.

Government and Industry Investments in Hydrogen Technology

We actively engage with industry leaders and government bodies to drive investment and research in hydrogen technology, ensuring that we remain at the cutting edge of developments.

Choosing the Right Hydrogen Tank for Your Needs

Assessing Your Hydrogen Storage Requirements

Our team at Red River LLC works closely with you to assess your specific hydrogen storage needs, ensuring the tank you choose is the perfect fit for your application.

Why Type 3 Tanks Might Be Right for You

If durability and cost-effectiveness are your priorities, our Type 3 tanks might be the ideal choice for your operations.

The Ideal User Profile for Type 4 Tanks

For those prioritizing cutting-edge technology, weight savings, and efficiency, Type 4 tanks offer a future-proof solution.

Need a reliable partner?

FAQ: Pressure Vessels by Red River LLC

1: What are the key factors to consider when selecting a material for pressure vessel construction?

When selecting materials for pressure vessel construction, it’s crucial to consider the operating environment, including temperature and pressure, the corrosive nature of the contents, the required strength-to-weight ratio, and compliance with industry standards like ASME. Materials typically range from carbon steel for high-temperature resilience to stainless steel for corrosion resistance and advanced composites for lightweight applications.

2: How does Red River LLC ensure the longevity and durability of the pressure vessels they manufacture?

Red River LLC ensures longevity and durability through a combination of high-quality materials, advanced welding techniques, and rigorous quality control measures. Each vessel undergoes extensive testing to withstand the demands of its operational environment. Additionally, we adhere to a strict maintenance and inspection schedule post-manufacture to prevent degradation over time.

3: Can pressure vessels be customized to fit specific operational needs, and what is the process for this?

Absolutely, pressure vessels can be extensively customized. The process begins with a detailed consultation to understand the specific needs, including pressure ratings, volume, and material preferences. From there, Red River LLC employs advanced design software to create a tailored solution, which is then brought to life through precision engineering and manufacturing processes.

4: What advancements in pressure vessel technology can we expect to see in the near future?

The future of pressure vessel technology is likely to see advancements in materials science, with the development of even more resilient and lightweight composites. Additionally, we anticipate further integration of IoT sensors for real-time monitoring and predictive maintenance, as well as improvements in manufacturing techniques like 3D printing for complex components.

5: How do environmental regulations impact the design and manufacturing of pressure vessels?

Environmental regulations significantly impact the design and manufacturing of pressure vessels. These regulations dictate the choice of materials, the manufacturing processes, and the operational efficiency of the vessels to minimize environmental impact. Red River LLC stays ahead of these regulations by adopting eco-friendly practices, such as using recyclable materials and reducing emissions during production.

Table of Contents

ToggleRelated Blog Post

- What is the difference between a pressure vessel and a compressor?

- What is the most common type of pressure vessel used in industry?

- What are the different types of pressurised tanks?

- How many types of ship vessels are there?

- What is a Type 3 pressure vessel?

- What is a typical pressure vessel?

- What is the difference between Class 1 and Class 2 pressure vessels?

- Which pressure vessel is strongest?

- What are the four most common types of heads for pressure vessels?

- What is the difference between Type 3 and Type 4 hydrogen tanks?

- What are different codes used for pressure vessels?

- What is a Category 3 pressure area?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.