Understanding the Differences: Piping vs. Pressure Vessel | Red River LLC

Table of Contents

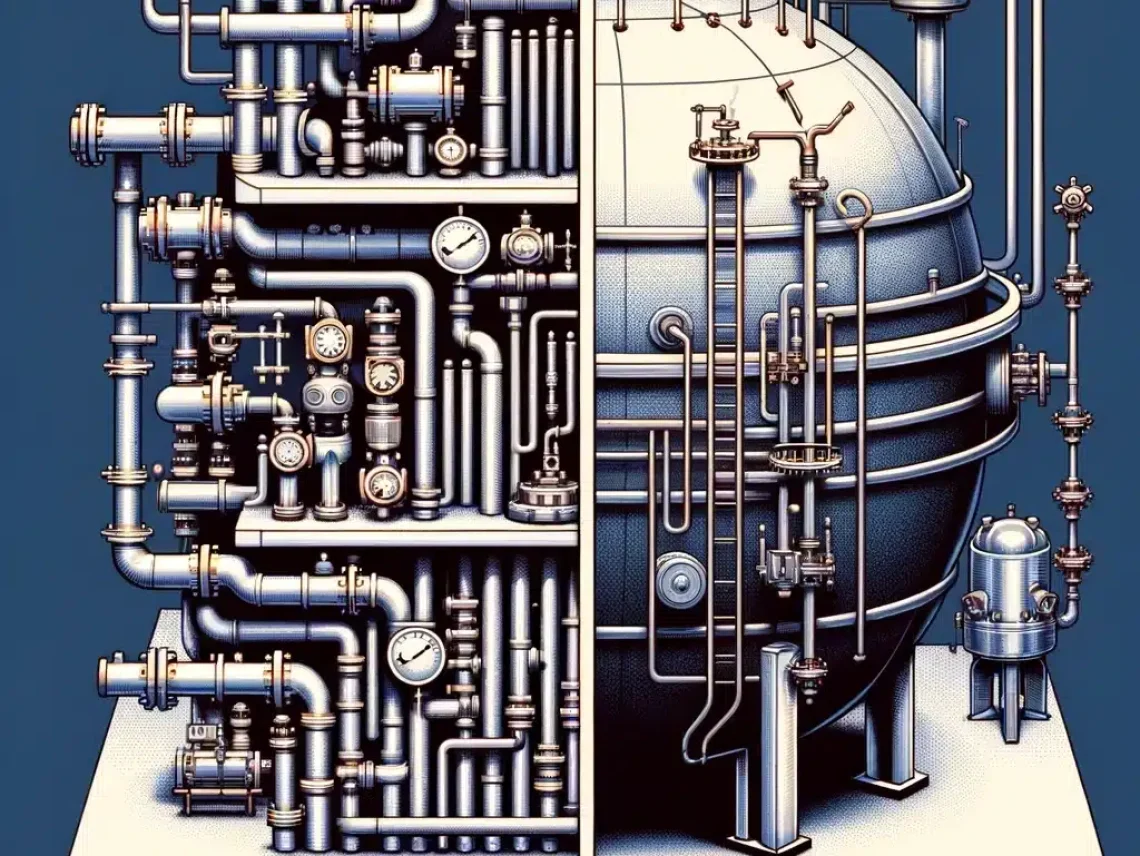

ToggleIntroduction to Piping and Pressure Vessels

Piping systems are the lifelines of many industries, from oil and gas to power generation. They are designed to transport fluids, gases, and sometimes even solids from one location to another. Think of them as the veins and arteries of a facility, ensuring that everything flows smoothly and efficiently. At Red River, we’ve been involved in numerous piping projects, catering to diverse sectors like commercial/public works and biogas. Our commitment? To deliver piping solutions that stand the test of time, ensuring that our clients can focus on what they do best.

Defining Pressure Vessels: Basics and Functions

Pressure vessels, on the other hand, are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. These vessels are pivotal in industries like minerals/elements and power generation. At Red River, we specialize in manufacturing these vessels, ensuring they meet or even exceed ASME requirements. Our dedication to safety and quality means that when you partner with us, you’re not just getting a product; you’re investing in peace of mind. Our clients, ranging from startups to international entities, trust us with their most valuable projects. And we never let them down.

Importance in Industrial Applications

Both piping and pressure vessels are integral to the functioning of many industries. They ensure that operations run smoothly, safely, and efficiently. Whether it’s transporting crude oil across miles or ensuring that a power plant operates without hitches, these systems are indispensable.

At Red River, we understand the nuances of both. Our team, led by industry veteran Reilly Sasse, is dedicated to ensuring that our solutions not only meet but exceed industry standards. We’re here for the doers, the go-getters, the ones making a difference every day. Our promise? To look you in the eye, offer a firm handshake, and deliver on our word.

Key Differences Between Piping and Pressure Vessels

Design and Structural Variations

While piping is designed to transport substances, pressure vessels are containers built to store or process fluids under pressure. The design of piping focuses on flow efficiency, whereas pressure vessels emphasize containment and safety under high pressure.

Functional Differences

Piping facilitates the movement of fluids or gases between locations, ensuring seamless operations. In contrast, pressure vessels are about containment, often used for reactions, storage, or heat exchange.

Material Selection and Composition

Piping materials prioritize corrosion resistance and flow efficiency. Pressure vessels, however, require materials that can withstand high pressures, often using thicker and more robust metals.

The Role of Piping in Industries

Transportation of Fluids and Gases

In industrial settings, piping serves as the lifeline for the transportation of essential fluids and gases. It ensures that liquids, chemicals, steam, and gases are reliably conveyed from one location to another, whether within a plant or across vast distances. Piping systems are meticulously designed to accommodate the specific properties of each fluid or gas, such as temperature, pressure, and corrosiveness, thereby maintaining operational continuity and ensuring that processes run smoothly. The durability and reliability of industrial piping are vital for avoiding disruptions, preserving product quality, and optimizing production efficiency.

Piping Systems and Their Components

A comprehensive piping system includes more than just pipes; it is a complex network of valves, fittings, supports, and joints that work together to ensure the smooth flow of fluids and gases. Valves regulate flow and pressure, fittings connect different pipe sections, and supports prevent sagging or damage. Each component is engineered for specific industrial requirements, such as high temperatures, corrosive substances, or high-pressure conditions. The integrity of these components is critical for the safe and efficient operation of the piping system. Proper design, material selection, and periodic inspections are essential to maintain the system’s functionality and longevity.

Safety Protocols in Piping

Industrial piping systems are governed by strict safety protocols to prevent leaks, spills, and other hazards. Regular inspections and maintenance schedules are crucial to identifying and addressing potential issues before they escalate. Adherence to industry standards and regulatory requirements, such as those set by the ASME or OSHA, is essential for safe operations. Safety measures also include pressure-relief mechanisms, corrosion-resistant materials, and emergency shutoff valves, all of which work to protect both personnel and the environment from potential risks. Implementing these protocols reduces the likelihood of accidents, minimizes downtime, and ensures compliance with safety regulations.

Dive into Pressure Vessel Technologies

Types of Pressure Vessels

Pressure vessels come in various forms, each tailored to specific industrial needs. Common types include storage tanks, reactors, boilers, and autoclaves, each serving a distinct purpose. Storage tanks, for example, hold gases or liquids at high pressures, while reactors facilitate chemical reactions under controlled conditions. Boilers produce steam for power generation, and autoclaves use high-pressure steam for sterilization processes. The design of each vessel is based on factors like pressure, temperature, and the nature of the substance it will contain. The diversity in types allows industries to select the most suitable vessel for their unique processes.

Pressure Vessel Applications

Pressure vessels are indispensable in a wide range of industries, from power generation to chemical processing and beyond. In power plants, they store and manage steam to drive turbines for electricity production. In the chemical industry, they serve as reactors that allow chemical reactions to occur under specific temperature and pressure conditions, thereby enhancing efficiency and safety. Pharmaceutical manufacturers use autoclaves for sterilization, while the oil and gas sector relies on pressure vessels for the storage and transport of hydrocarbons. These applications underscore the versatility and importance of pressure vessels in supporting critical industrial functions.

Standards and Regulations

Pressure vessels are governed by stringent standards, like the ASME, ensuring safety and reliability.

Comparative Analysis: Piping vs. Pressure Vessels

Cost Implications

While piping costs focus on length and material, pressure vessels consider volume, material, and safety features.

Durability and Lifespan

Piping often has a longer lifespan due to less intense internal conditions, whereas pressure vessels face wear from high internal pressures.

Maintenance and Inspection

Both require regular checks, but pressure vessels demand more rigorous inspections due to their critical nature.

Real-life Applications and Case Studies

Piping Systems in the Oil and Gas Industry

Piping systems are the backbone of the oil and gas sector, transporting crude and refined products across vast distances. Their efficiency ensures energy reaches homes and businesses.

Pressure Vessels in Power Plants

In power plants, pressure vessels like boilers and reactors play a pivotal role. They contain steam or other fluids under pressure, driving turbines and generating electricity.

Innovations and Technological Advancements

From corrosion-resistant materials to smart monitoring systems, innovations are enhancing the efficiency and safety of both piping and pressure vessels.

Safety and Compliance in Piping and Pressure Vessels

Safety Measures for Piping Systems

Piping safety includes regular inspections, anti-corrosion treatments, and pressure monitoring to prevent leaks and bursts.

Pressure Vessel Safety Protocols

Safety in pressure vessels involves rigorous material testing, pressure relief systems, and periodic inspections.

Compliance and Certification Processes

Both piping and pressure vessels adhere to strict standards, with certifications like ASME ensuring global safety benchmarks are met.

Future Trends: Piping and Pressure Vessels

Sustainable and Eco-friendly Solutions

The industry is moving towards greener materials and processes, reducing environmental impact.

Technological Innovations on the Horizon

From AI-driven monitoring to advanced materials, technology is reshaping the industry.

Market Predictions and Growth Opportunities

With growing energy demands, the market for piping and pressure vessels is poised for significant growth.

Red River LLC's Expertise in Piping and Pressure Vessels

Our Commitment to Quality and Safety

At Red River, we prioritize top-notch quality and an unwavering dedication to safety in all our projects.

Client Testimonials and Success Stories

Our clients, from startups to giants, vouch for our expertise, reliability, and partnership approach.

Why Choose Red River LLC?

With our deep industry knowledge, American values, and a client-first approach, Red River stands out as the partner of choice.

Need a reliable partner?

FAQ: Understanding Pressure Vessels and Piping Systems

What is the primary purpose of a pressure vessel?

A pressure vessel is a container specifically designed to store gases or liquids at a pressure substantially different from the ambient pressure. They are essential in various industries, such as power generation, where they might be used as boilers or reactors. Their primary purpose is to contain and manage the high-pressure contents safely, ensuring that the surrounding environment and workers are not at risk.

How do piping systems differ from regular pipes?

While a regular pipe is a simple cylindrical conduit used to move fluids, a piping system is a complex network of pipes combined with fittings, valves, and other components. This system is designed to transport fluids or gases between different parts of a facility or even across vast distances. Piping systems are meticulously planned to ensure efficient flow, safety, and accessibility for maintenance.

Are there specific materials recommended for pressure vessels due to their high-pressure nature?

Yes, the materials used for pressure vessels are chosen based on their ability to withstand high pressures and, often, high temperatures. Common materials include carbon steel, stainless steel, and other alloy steels. The choice of material also depends on the type of fluid or gas the vessel will contain, as some substances can be corrosive or reactive with certain materials.

How often should pressure vessels and piping systems be inspected?

The frequency of inspections depends on the industry standards, the type of fluid or gas contained, and the specific operational conditions. However, regular inspections are crucial. For pressure vessels, many industries follow the standards set by the American Society of Mechanical Engineers (ASME). Typically, an annual inspection is recommended, but in some high-wear environments, more frequent checks might be necessary.

What are the potential risks if a pressure vessel or piping system fails?

The failure of a pressure vessel or piping system can lead to catastrophic results. This includes the explosive release of the contained gas or fluid, which can cause significant damage to the facility and pose a severe risk to worker safety. In addition to physical harm, there can be environmental implications, especially if the released substance is hazardous. Such incidents can also lead to operational downtimes, financial losses, and potential legal consequences.

Table of Contents

ToggleRelated Blog Post

- Are boilers fired pressure vessels?

- Is a steam turbine a pressure vessel?

- What is the difference between piping and pressure vessel?

- What is the difference between a pressure vessel and a column?

- What is the difference between a surge vessel and a pressure vessel?

- What is the difference between a pressure vessel and a high-pressure vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.