Understanding Air Tanks as Pressure Vessels

Table of Contents

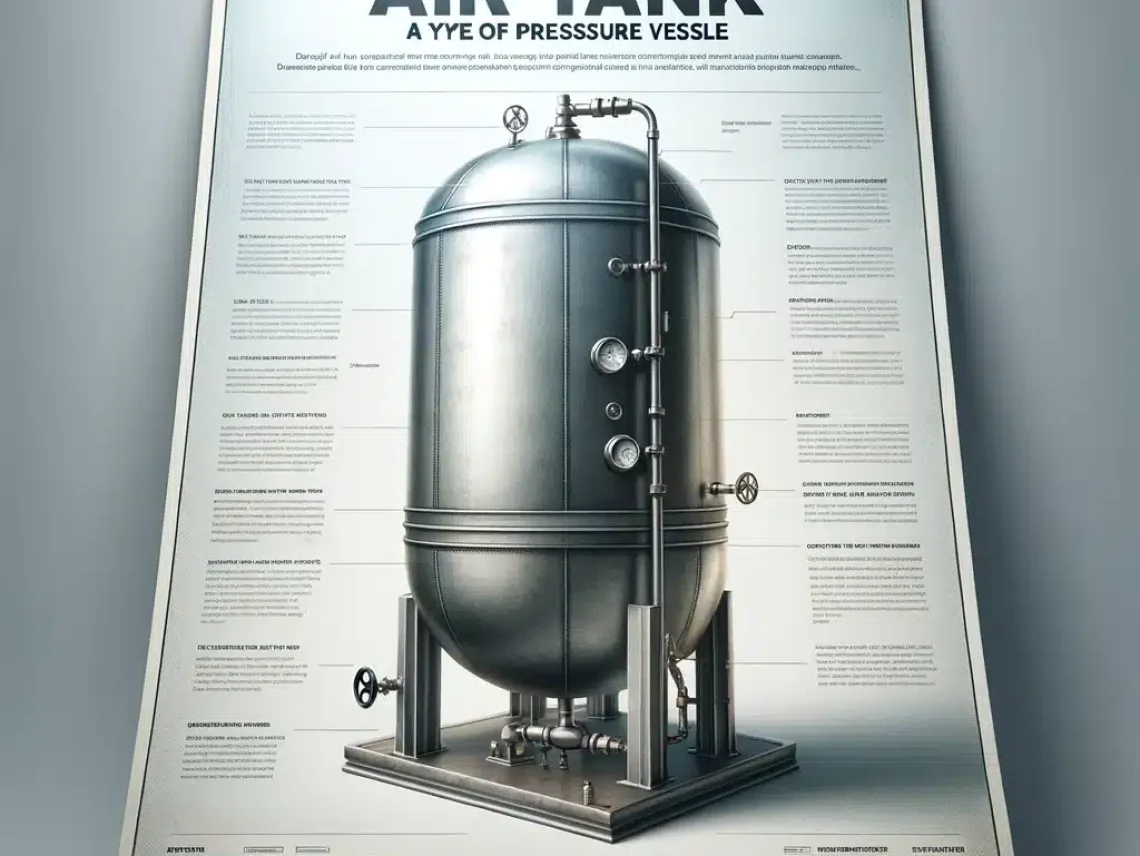

ToggleIntroduction to Air Tanks and Pressure Vessels

Air tanks, a common sight in numerous industries, are more than just storage units. They are the backbone of operations in sectors like oil and gas, power generation, and biogas. At Red River, we see air tanks as vital components that store compressed air, essential for machinery operation and process control. Our air tanks are designed with precision, ensuring they meet the rigorous demands of your industry, whether it’s for high-pressure applications or specific environmental conditions.

The Basic Concept of Pressure Vessels

Now, let’s talk about pressure vessels. These are not just containers; they are engineered systems designed to safely hold gases or liquids at a pressure substantially different from the ambient environment. This is where our expertise at Red River shines. We understand that each pressure vessel has its unique set of requirements based on its application. Our commitment to safety and quality means every vessel we produce adheres to the strictest industry standards, including ASME compliance, ensuring reliability and peace of mind for our clients.

Air Tanks and Pressure Vessels: Are They the Same?

So, is an air tank a pressure vessel? Absolutely! Every air tank we manufacture at Red River is a type of pressure vessel, specifically designed to handle and store compressed air safely and efficiently. However, not all pressure vessels are air tanks. Our range of pressure vessels extends beyond air storage, catering to diverse needs across various industries, including commercial/public works and mineral/element extraction.

Characteristics of Pressure Vessels in Air Tanks

Material Composition of Air Tanks

At Red River LLC, we understand that the material composition of air tanks is crucial. Our tanks are crafted from robust materials like carbon steel or stainless steel, ensuring durability and resistance to corrosion and extreme conditions.

Pressure Ratings and Safety Standards

Adhering to rigorous safety standards, our air tanks are designed with specific pressure ratings to handle varying industrial demands, ensuring operational safety and compliance with regulatory requirements.

Design and Construction of Air Tank Pressure Vessels

Our air tanks are engineered with precision, incorporating advanced design techniques to optimize performance, longevity, and safety, tailored to meet the unique needs of our clients.

Types of Air Tanks as Pressure Vessels

Stationary vs Portable Air Tanks

We offer both stationary and portable air tanks, providing flexible solutions for different operational environments, from fixed industrial setups to mobile applications.

High-Pressure Air Tanks for Industrial Applications

Our high-pressure air tanks are designed for demanding industrial applications, ensuring reliability and efficiency under high-pressure conditions.

Specialized Air Tanks for Diverse Industries

Tailored to various sectors, our specialized air tanks meet the unique requirements of industries like biogas, power generation, and mineral extraction.

The Role of Pressure Vessels in Air Tank Systems

Storage and Management of Compressed Air

Our air tanks efficiently store and manage compressed air, crucial for consistent operation and energy efficiency in industrial processes.

Pressure Regulation and Control Mechanisms

Incorporating advanced pressure regulation and control mechanisms, our air tanks ensure precise pressure management, vital for safety and operational accuracy.

Safety Features in Air Tank Pressure Vessels

Safety is paramount in our design, featuring multiple safety components to prevent overpressure incidents and ensure secure operation.

Legal and Safety Regulations for Air Tank Pressure Vessels

Compliance with Industry Standards

Red River LLC’s air tanks comply with industry standards like ASME, ensuring legal compliance and operational excellence.

Regular Inspection and Maintenance Requirements

We emphasize the importance of regular inspections and maintenance for the long-term reliability and safety of our air tanks.

Certification Processes for Safety Assurance

Our rigorous certification processes guarantee that each air tank meets the highest safety and quality standards.

Air Tanks and Their Classification as Pressure Vessels

Categories of Air Tanks Based on Pressure Capacity

We classify our air tanks based on pressure capacity to suit various industrial applications, ensuring optimal performance and safety.

The Importance of Proper Classification

Proper classification of air tanks is vital for ensuring they meet specific operational requirements and safety regulations.

Understanding the Different Uses of Classified Air Tanks

Our diverse range of classified air tanks caters to different industrial needs, from energy production to environmental management.

Innovations in Air Tank Pressure Vessel Design

Advanced Materials and Technologies

At Red River LLC, we’re pioneering the use of advanced materials and technologies in air tank design. Our focus is on lightweight, durable materials that enhance performance and longevity.

Enhancing Efficiency and Safety

Efficiency and safety are at the forefront of our design philosophy. We integrate innovative features that optimize operational efficiency while bolstering safety standards.

Future Trends in Air Tank Design

We’re always looking ahead, anticipating future trends in air tank design to ensure our products remain at the cutting edge of technology and functionality.

Case Studies: Air Tanks in Action

Real-World Applications of Air Tank Pressure Vessels

Our air tanks have a proven track record across various industries, demonstrating versatility and reliability in real-world applications.

Success Stories from Various Industries

We take pride in our success stories, showcasing how our air tanks have contributed to the success of diverse industrial projects.

Lessons Learned and Best Practices

Drawing from our extensive experience, we share key lessons and best practices, continually refining our approach to air tank manufacturing.

Purchasing Guide for Air Tank Pressure Vessels

Factors to Consider When Buying an Air Tank

When purchasing an air tank, consider factors like capacity, pressure ratings, material, and compliance with industry standards.

Red River LLC’s Range of Air Tanks

Explore our wide range of air tanks, each designed to meet specific industrial needs with precision and quality.

Custom Solutions for Specific Needs

We specialize in custom solutions, tailoring air tanks to meet your unique requirements and challenges.

Maintenance and Care of Air Tank Pressure Vessels

Routine Inspection and Upkeep

Regular inspection and maintenance are key to ensuring the longevity and optimal performance of your air tank.

Troubleshooting Common Issues

Our team is skilled in troubleshooting common issues, ensuring quick and efficient resolution to maintain operational continuity.

Longevity and Performance Optimization

We focus on strategies to maximize the longevity and performance of your air tanks, ensuring they deliver value over time.

Need a reliable partner?

Frequently Asked Questions (FAQs) About Pressure Vessels

What are the key factors to consider when selecting materials for pressure vessels?

When selecting materials for pressure vessels, it’s crucial to consider factors like the operating environment, temperature, pressure levels, and the type of substance being contained. Materials should have high tensile strength, corrosion resistance, and durability. Common choices include carbon steel, stainless steel, and alloys like Hastelloy or Inconel, depending on the specific application requirements.

How do pressure ratings affect the design and use of a pressure vessel?

Pressure ratings determine the maximum internal pressure a vessel can safely withstand. This rating influences the thickness of the vessel walls, the type of joints and welds used, and the overall design. Higher pressure ratings typically require more robust construction to ensure safety and integrity under operating conditions.

What are the differences between ASME and non-ASME pressure vessels, and why does it matter?

ASME pressure vessels comply with the standards set by the American Society of Mechanical Engineers, known for their stringent safety and quality guidelines. Non-ASME vessels may not adhere to these standards, potentially affecting their safety and performance. Choosing ASME-compliant vessels ensures a higher level of safety and is often a requirement in certain industries and regions.

Can pressure vessels be customized for specific industrial applications, and what are the limitations?

Yes, pressure vessels can be customized to meet specific industrial needs. Customization can include size, shape, material, internal linings, and additional features like heating or cooling jackets. However, the limitations lie in adhering to safety standards, material capabilities, and the feasibility of the design under the intended operating conditions.

What are the emerging trends in pressure vessel technology, and how are they enhancing safety and efficiency?

Emerging trends in pressure vessel technology include the use of advanced composite materials for lighter, stronger vessels, and the integration of smart sensors for real-time monitoring of pressure, temperature, and potential cracks. These innovations enhance safety by providing better resistance to harsh conditions and enabling proactive maintenance, thereby improving the overall efficiency and lifespan of the vessels.

Table of Contents

ToggleRelated Blog Post

- How do pressure vessels fail?

- What is a steel pressure vessel?

- Is an air tank a pressure vessel?

- Why do pressure vessels explode?

- Is an air compressor a pressure vessel?

- What is an external pressure vessel?

- What material are vessels made of?

- What does a pressure vessel consist of?

- What is a pressure vessel also known as?

- What is the definition of simple pressure vessel?

- What are the disadvantages of pressure vessels?

- What is an example of an unfired pressure vessel?

- How thick are pressure vessel walls?

- How do you weld a pressure vessel?

- What is the most common pressure vessel material?

- Which of the following are a type of a pressure vessel?

- What is the difference between a boiler and presure vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.