Understanding Pressure Vessel Welding with Red River LLC

Table of Contents

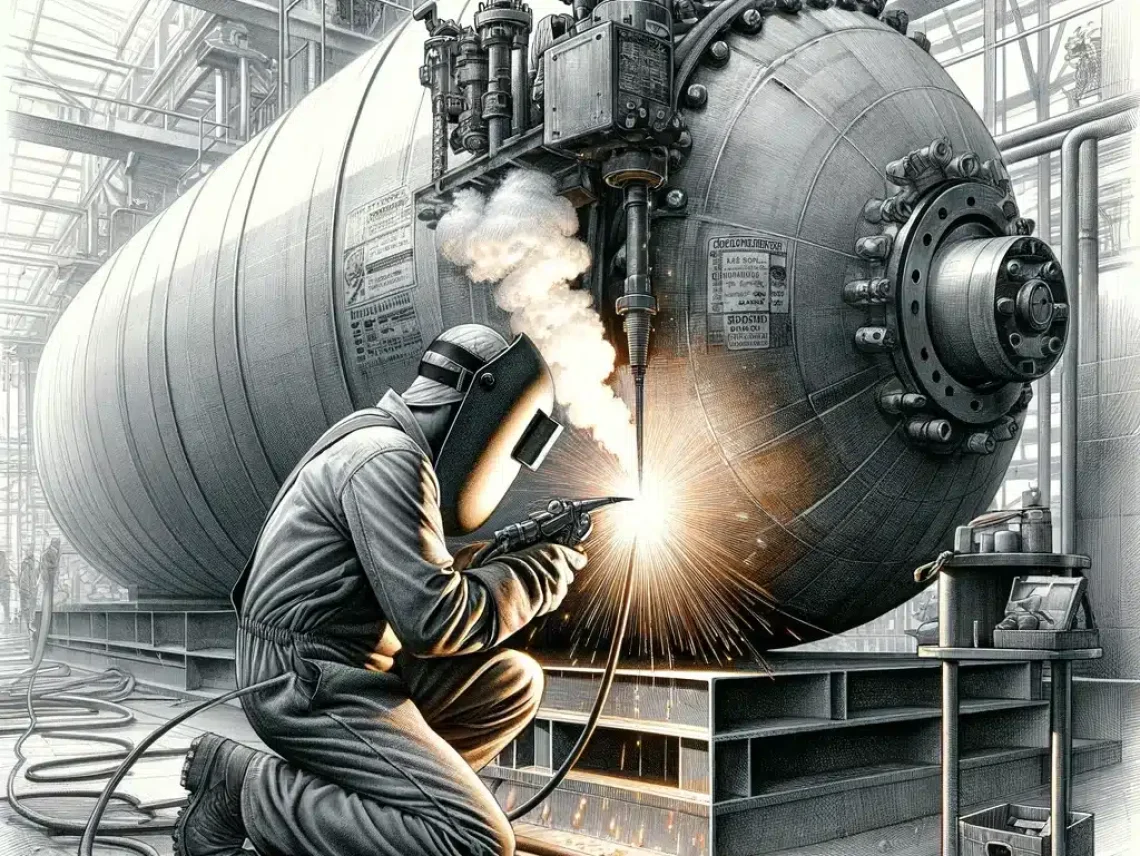

ToggleIntroduction to Pressure Vessel Welding

At Red River LLC, we apprehend that pressure vessel welding is more than only a technique; it is an art that combines ability, precision, and a deep know-how of materials and techniques. Pressure vessel welding involves the meticulous becoming a member of metals to shape bins designed to keep gases or drinks at a pressure drastically one of a kind from the ambient pressure. This manner is critical in industries like oil and fuel, power generation, and biogas, wherein safety and reliability are paramount.

The Importance of Pressure Vessel Welding in Industry

In the sector of business programs, the position of pressure vessel welding can not be overstated. These vessels are pivotal in several sectors, together with oil and gas, commercial/public works, and electricity technology. They play an essential position in our society’s infrastructure, retaining and processing materials under high pressure in secure, managed surroundings.

Red River LLC's Approach to Quality Welding

At Red River LLC, we pleasure ourselves with our method of best welding. Our team, trained in the modern-day superior welding procedures, is at the coronary heart of our operations. We understand that each pressure vessel challenge is unique, requiring a tailored approach that considers the particular needs and challenges of the software.

Types of Pressure Vessels

Common Materials Used in Pressure Vessels

Pressure vessels at Red River LLC are made from loads of substances, each decided on for its precise homes and suitability for precise applications. Common substances consist of carbon metallic for durability, chrome steel for corrosion resistance, and alloy substances for high-pressure environments. Our know-how permits us to propose fine cloth for your particular wishes.

Design Standards for Different Pressure Vessels

Our pressure vessels are designed to adhere to rigorous requirements, ensuring safety, performance, and reliability. We follow ASME requirements, tailoring every layout to satisfy the unique requirements of the enterprise, whether it is oil and gas, strength technology, or biogas.

Innovations in Pressure Vessel Technology

At Red River, we embrace technological advancements, continuously innovating to enhance the performance and protection of our pressure vessels. From integrating new materials to adopting modern-day layout techniques, we are at the leading edge of the pressure vessel era.

Welding Techniques for Pressure Vessels

Overview of Welding Methods

We employ more than a few welding strategies, everyone selected for its suitability to the mission. Our professional welders are adept in numerous techniques, ensuring the highest satisfaction of welds for each pressure vessel.

TIG Welding for Precision and Strength

TIG welding is a key approach in our arsenal, imparting precision and energy. It’s perfect for exceptional, vital welds, especially in chrome steel and aluminum vessels.

MIG Welding: A Versatile Approach

MIG welding is any other flexible method we use. It’s faster than TIG welding and appropriate for quite a few materials, making it a cross-to method for plenty of tasks.

Safety Standards in Pressure Vessel Welding

Adhering to International Safety Protocols

Safety is paramount in pressure vessel welding. We adhere to global safety protocols, ensuring that each vessel meets global safety standards.

Red River LLC's Safety Measures and Certifications

Our protection measures and certifications are a testament to our commitment to protection. We’re licensed in numerous welding strategies, making ensure the highest safety requirements in every venture.

Importance of Regular Inspections and Maintenance

Regular inspections and upkeep are critical for the sturdiness and protection of pressure vessels. We emphasize the significance of these practices in our operations.

Pressure Vessel Welding Certifications

Necessary Qualifications for Welders

Our welders hold the essential certifications, making sure they are geared up with state-of-the-art abilities and an understanding of pressure vessel welding.

Training Programs Offered by Red River LLC

We offer comprehensive schooling programs, keeping our group updated with the ultra-modern techniques and protection standards inside the enterprise.

Renewing and Upgrading Welding Certifications

We inspire our welders to continually renew and improve their certifications, staying beforehand inside the ever-evolving field of welding generation.

Advanced Welding Technologies

Innovations in Welding Equipment

We make investments in modern welding gadgets, embracing innovations that decorate efficiency and fine in our welding tactics.

Automation in Pressure Vessel Welding

Automation plays a huge role in our welding processes, growing precision and consistency in our pressure vessel production.

Future Trends in Welding Technology

We keep an eye on destiny developments in welding generation, ensuring that Red River LLC stays at the cutting fringe of pressure vessel production.

Quality Control in Welding Processes

Red River LLC's Quality Assurance Practices

At Red River LLC, a satisfactory warranty in welding approaches isn’t just a protocol; it is a dedication. Our comprehensive high-quality guarantee practices involve meticulous oversight at each degree of the welding manner. From deciding on the greatest substances to employing advanced welding techniques, we make sure that each weld meets our stringent standards.

Testing Methods for Weld Integrity

To guarantee the integrity of our welds, we rent diverse trying-out methods. These consist of non-detrimental testing techniques like ultrasonic and radiographic testing, making sure that each weld is illness-free and able to withstand the needs of its supposed use.

Ensuring Longevity and Reliability in Welds

Our recognition of sturdiness and reliability is unwavering. By enforcing rigorous testing and first-class manipulation measures, we ensure that our welds no longer meet however exceed industry standards, supplying our clients with the assurance of durability and protection.

Custom Welding Solutions by Red River LLC

Tailored Services for Unique Projects

At Red River, we understand that each assignment has its specific demanding situations. That’s why we provide custom welding solutions, tailor-made to fulfill the particular requirements of your task. Our group works intently with customers to apprehend their needs and supply bespoke solutions.

Case Studies of Custom Welding Projects

Our portfolio of custom welding tasks showcases our versatility and expertise. From complex commercial applications to progressive designs, our case research shows our ability to tackle a diverse range of challenges with precision and excellence.

Consultation and Design Services

We provide complete consultation and layout offerings, supporting customers navigate the complexities of their welding projects. Our professional crew gives insights and steerage from the preliminary idea to the very last execution.

Environmental Considerations in Welding

Sustainable Practices in Welding

Sustainability is in the middle of our welding practices. We continuously are looking for ways to lessen our environmental footprint, implementing eco-friendly strategies and materials in our welding techniques.

Reducing Environmental Impact

Our dedication to reducing environmental impact involves optimizing resource use, minimizing waste, and employing purifiers, and greater green welding technologies.

Compliance with Environmental Regulations

Compliance with environmental guidelines is non-negotiable at Red River. We adhere to all applicable environmental laws and hints, making sure our welding practices are not simplest efficient but additionally environmentally responsible.

The Future of Pressure Vessel Welding

Emerging Trends and Technologies

The destiny of pressure vessel welding is formed by emerging developments and technology. At Red River, we live in advance of the curve, embracing improvements that beautify our welding skills and performance.

The Role of AI and Machine Learning

AI and systems getting to know are revolutionizing the welding enterprise. We are exploring that technology to beautify precision, enhance nice control, and optimize our welding tactics.

Preparing for the Future in Welding Industry

Preparing for the future, we put money into education and era, ensuring that our group and our practices are prepared to satisfy the evolving needs of the welding enterprise.

Need a reliable partner?

Frequently Asked Questions About Pressure Vessel Manufacturing

What are the key factors to consider when selecting materials for pressure vessels?

Selecting the right fabric for a pressure vessel is crucial for its performance and protection. Key factors include the vessel’s working pressure and temperature, the sort of substance it’ll comprise (e.g., gas, liquid, corrosive substances), and the surroundings wherein it will function. Materials like carbon metal, stainless steel, and alloys are usually used, each supplying exclusive blessings like corrosion resistance, energy, and sturdiness.

How do advancements in welding technology impact the quality of pressure vessels?

Advancements in the welding era have extensively advanced first-rate pressure vessels. Modern techniques like automatic welding, precision TIG, and MIG welding beautify the strength, sturdiness, and protection of the welds. These technologies additionally permit greater steady satisfaction, lessen the likelihood of defects, and enable extra complicated designs.

What are the most critical safety standards and certifications for pressure vessel manufacturing?

The most critical safety requirements for pressure vessel production consist of the ASME Boiler and Pressure Vessel Code, which units the benchmark for the layout, fabrication, and inspection of boilers and pressure vessels. Certifications just like the NBBI R Stamp and ASME’s U & R stamps are vital for manufacturers, indicating compliance with national safety standards and a dedication to fines.

Can pressure vessels be customized for specific industrial applications, and what are the limitations?

Yes, pressure vessels can be noticeably customized to fulfill specific business desires. This customization can consist of size, form, fabric, inner additives, and outside fittings. However, all customizations should adhere to protection and enterprise requirements. The boundaries normally relate to the physical homes of substances used and the operational conditions they ought to withstand, along with pressure limits and corrosion resistance.

How does environmental sustainability factor into pressure vessel manufacturing?

Environmental sustainability in pressure vessel production involves using green materials, minimizing waste, and imposing electricity-green production processes. Manufacturers are an increasing number of adopting practices like recycling materials, using superior technologies to reduce emissions, and designing vessels that require less electricity to operate. Compliance with environmental rules is also a key factor, ensuring that manufacturing techniques do not adversely affect the environment.

Table of Contents

ToggleRelated Blog Post

- How many hours do welders work?

- What is a 3g welder job description?

- What skills are required to be a welder?

- When should pressure welding be used?

- What are the benefits of being a welder?

- What is pressure welding also known as?

- What are 5 key responsibilities for a welder?

- What are the responsibilities of a ship welder?

- What are the two basic tools required by a welder?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.