Understanding Pressure Vessel Fabrication at Red River LLC

Table of Contents

ToggleIntroduction to Pressure Vessel Fabrication

At Red River LLC, we see pressure vessel fabrication as greater than only a manufacturing system; it is an art that combines skill, precision, and deep know-how of engineering and materials. For example, pressure vessel fabrication entails the meticulous construction of vessels designed to hold gases or liquids at a pressure extensively distinct from ambient pressure. Moreover, our team at Red River makes a specialty of this difficult procedure, making sure each vessel is crafted to satisfy the particular wishes of our clients, whether they’re within the oil and gasoline, energy technology, or biogas industries.

The Importance of Pressure Vessels in Industry

Pressure vessels are the unsung heroes in many industries and have a vital function in a wide variety of applications. For instance, from storing compressed gases and beverages in the oil and fuel sector to keeping steam in power generation facilities, these vessels are vital to the operations of many sectors that drive our economy. Consequently, at Red River, we recognize the pivotal function these vessels play. Therefore, we are dedicated to delivering top-notch products that not only meet but exceed industry standards. Our pressure vessels are designed to be strong, efficient, and secure, ensuring they contribute positively to your operations.

Red River LLC's Approach to Quality and Safety

At Red River, we don’t simply construct pressure vessels; we craft solutions that encompass American values of hard work, integrity, and excellence. Additionally, our approach to fabrication is rooted in a commitment to safety and precision. Since each project carries its unique demands and requirements, we tailor our processes to fulfill your specific needs. As a result, our team, led by experienced veterans like Reilly Sasse, ensures that every vessel we produce is not only compliant with ASME standards but also aligns with our rigorous internal control measures.

Key Materials Used in Pressure Vessel Construction

Overview of Common Materials

Pressure vessels at Red River LLC are built for the usage of a wide range of substances, each selected for its particular properties and suitability for unique applications. For example, common substances encompass carbon metallic, stainless steel, and alloys like nickel and aluminum. These materials are recognized for their strength, sturdiness, and resistance to corrosion and extreme temperatures.

Material Selection Criteria

Selecting the right material is essential. Therefore, we consider several factors, such as the vessel’s operating environment, the nature of the substances it will contain, and the specified pressure and temperature conditions. This ensures optimal performance and durability of the vessels.

Innovations in Material Technology at Red River LLC

We’re at the forefront of material advancements, constantly exploring new materials and treatments to enhance the performance of our pressure vessels. For instance, innovations like corrosion-resistant coatings and superior alloys exemplify our commitment to delivering cutting-edge solutions.

Design and Engineering of Pressure Vessels

Principles of Pressure Vessel Design

Our design principles emphasize safety, efficiency, and compliance with rigorous industry standards. Moreover, we focus on elements like pressure distribution, temperature tolerance, and material properties to ensure each vessel meets the stringent demands of its intended use.

Advanced Engineering Techniques

Red River LLC employs advanced engineering techniques, such as computer-aided design (CAD) and finite element analysis (FEA), to model and simulate pressure vessel performance under various conditions. As a result, we ensure robust and reliable designs for our customers.

Custom Design Solutions by Red River LLC

We focus on custom design solutions, tailoring each vessel to meet the specific needs of our customers. Whether it involves a unique size, form, or material requirement, our team is equipped to deliver bespoke solutions that align with your requirements.

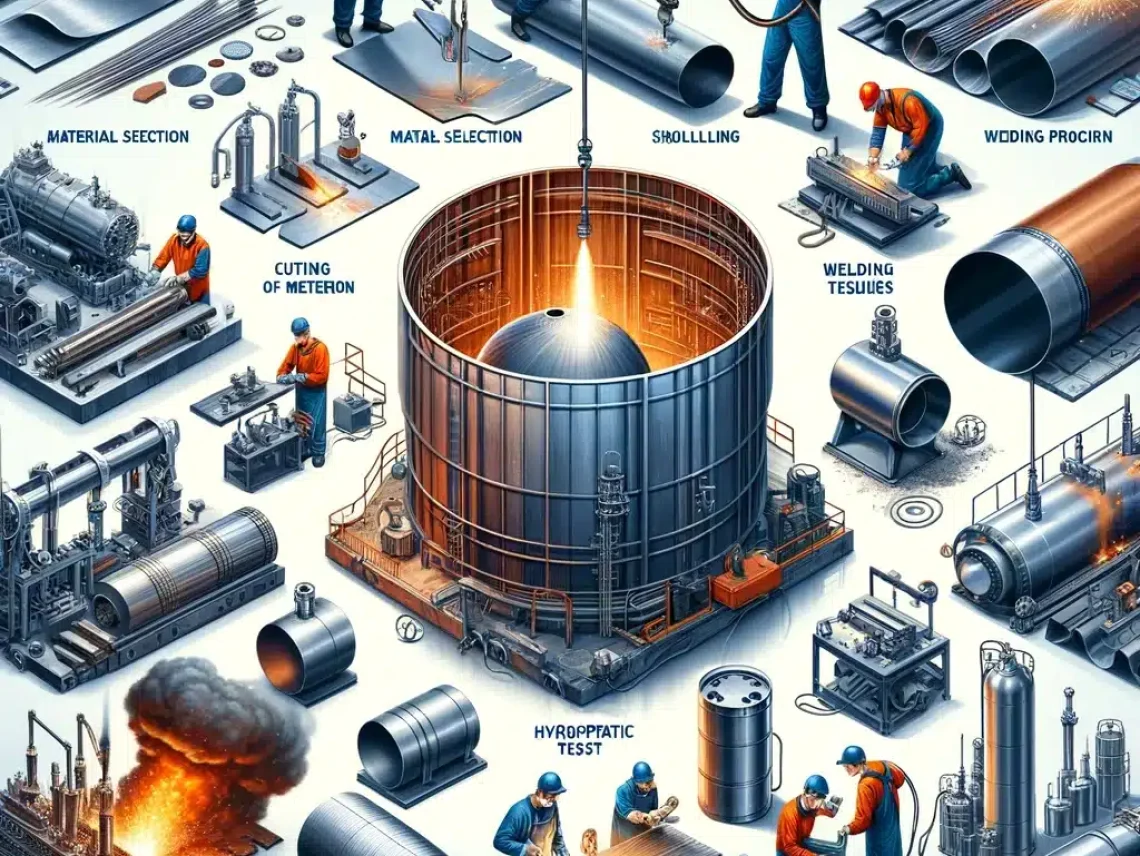

The Fabrication Process Step-by-Step

Initial Planning and Design Review

Every project begins with thorough planning and an in-depth design review. In this phase, we ensure that every detail meets the customer’s specifications and industry standards.

Cutting and Shaping Materials

Using state-of-the-art equipment, our skilled technicians precisely cut and shape materials to form the components of the pressure vessel. Furthermore, this process adheres strictly to the exact specifications of the design.

Assembling Components

The components are meticulously assembled, ensuring perfect alignment and structural integrity. This step is critical for the overall quality and performance of the completed vessel.

Welding Techniques in Pressure Vessel Fabrication

Importance of Precision Welding

Precision welding is critical in pressure vessel fabrication. Specifically, it guarantees the strength and integrity of the vessel, especially under high-pressure conditions.

Welding Methods Used by Red River LLC

We utilize a variety of welding techniques, including TIG, MIG, and arc welding, which are selected based on the material and design specifications of each vessel. By using these methods, we ensure optimal performance and durability.

Ensuring Weld Integrity and Safety

Our welding procedures are rigorously monitored and tested to ensure the highest levels of weld integrity and safety. Additionally, we adhere to strict industry requirements and best practices, which highlight our commitment to quality.

Testing and Quality Assurance Measures

Non-Destructive Testing (NDT) Methods

We employ advanced NDT methods, such as ultrasonic and radiographic testing, to locate any imperfections or weaknesses within the vessel without causing damage. As a result, these methods provide reliable evaluations of the vessel’s quality.

Pressure and Leak Testing

Each vessel undergoes thorough pressure and leak testing to confirm it can manage operational pressures and detect any potential leaks. This step ensures safety and functionality before deployment.

Red River LLC's Quality Assurance Protocols

Our quality assurance protocols include meticulous inspection and testing at every stage of the fabrication process. Ultimately, this ensures that every pressure vessel meets our high standards of safety and performance.

Customization Options in Pressure Vessel Fabrication

Tailoring to Specific Industry Needs

At Red River LLC, we recognize that every industry has specific requirements for pressure vessels. Whether it’s for oil and fuel, biogas, or power generation, we tailor our vessels to satisfy the particular pressures, temperatures, and chemical properties required by your industry.

Custom Coatings and Linings

We offer various custom coatings and linings to enhance the durability and performance of our pressure vessels. These specialized treatments are designed to resist corrosion, face up to excessive temperatures, and address diverse chemical exposures.

Adapting to Unique Operational Requirements

Our crew excels in adapting designs to satisfy unique operational requirements, ensuring that each vessel no longer meets enterprise standards but also aligns perfectly with your particular operational desires.

Compliance and Certifications in Fabrication

Adhering to Industry Standards

Red River LLC is dedicated to adhering to the highest industry standards. Our vessels are designed and manufactured to meet or exceed all relevant guidelines and suggestions, making sure protection and reliability.

Certification Processes

Our fabrication manner consists of rigorous certification tactics. We make certain that every pressure vessel we produce is certified for satisfaction and compliance, giving you peace of thoughts about its performance and protection.

Red River LLC's Commitment to Compliance

Our commitment to compliance is unwavering. We stay abreast of modern guidelines and requirements, making sure that our products and tactics are continually up to date.

Advanced Technologies in Pressure Vessel Fabrication

Automation in Fabrication

We leverage automation in our fabrication tactics to decorate precision, performance, and consistency within the manufacturing of our pressure vessels.

Cutting-Edge Machining Tools

Our facility is prepared with modern-day machining equipment that allows us to address complex designs and excessive precision requirements quite simply.

Software and Design Innovations

We make use of trendy software and design improvements to ensure that our pressure vessels are at the leading edge of the era, imparting advanced overall performance and reliability.

The Role of Skilled Craftsmanship

Expertise of Red River LLC's Team

Our group at Red River LLC is our greatest asset. Their information in skilled craftsmanship is clear in every vessel we produce, combining traditional techniques with modern technology.

Ongoing Training and Skill Development

We invest in ongoing education and ability development to ensure our crew is prepared with modern know-how and techniques in pressure vessel fabrication.

The Art and Science of Fabrication

At Red River, we see fabrication as each an art and a technology. Our crew’s craftsmanship is subsidized by using scientific precision, resulting in products of the best first-rate.

Case Studies and Success Stories

Highlighting Diverse Industry Applications

Our case research displays the diverse programs of our pressure vessels throughout various industries, showcasing our versatility and expertise.

Client Testimonials

Hearing from our customers approximately their stories about our services and products is constantly profitable. Their testimonials talk about the fine and reliability of our work.

Showcase of Completed Projects

We take pride in showcasing our finished tasks, every telling a tale of challenges met and expectancies surpassed, underlining our commitment to excellence in pressure vessel fabrication.

Need a reliable partner?

Frequently Asked Questions About Pressure Vessel Fabrication

What are the key factors to consider when selecting materials for pressure vessel fabrication?

When deciding on materials for pressure vessel fabrication, it is important to recall elements including the running environment, the sort of substance the vessel will include, and the pressure and temperature conditions it’ll face. Materials need to be selected based on their electricity, corrosion resistance, and durability under unique operational situations. For example, stainless steel is frequently used for its corrosion resistance, at the same time as carbon steel might be selected for its energy and affordability.

How do advancements in technology impact pressure vessel fabrication?

Technological improvements have considerably impacted pressure vessel fabrication by using improving precision, performance, and protection. Automation and laptop-aided layout (CAD) allow for extra accurate and steady manufacturing. Innovations in welding and material generation have additionally more suitable the satisfaction and performance of pressure vessels, making them safer and more reliable in extreme situations.

What are the safety considerations in pressure vessel design and fabrication?

Safety is paramount in pressure vessel layout and fabrication. This includes adhering to strict industry requirements like ASME, undertaking rigorous checking out along with pressure and leak exams, and enforcing non-damaging checking out (NDT) strategies. Additionally, the layout should account for factors like pressure distribution, temperature tolerance, and ability to chemical reactions to ensure the vessel’s integrity and safety under operational conditions.

Can pressure vessels be customized for specific industry applications?

Yes, pressure vessels can be noticeably customized to fulfill the unique wishes of diverse industries. This customization can encompass length, form, fabric, inner linings, coatings, and further features like weather manipulation or specialized units. The customization guarantees that the vessel not simplest meets enterprise standards but additionally aligns with the particular operational necessities of various sectors such as oil and fuel, biogas, or energy era.

What role does skilled craftsmanship play in pressure vessel fabrication?

Skilled craftsmanship is essential in pressure vessel fabrication. It includes a blend of traditional techniques and cutting-edge eras. Craftsmen’s expertise in welding, assembling, and completing guarantees the structural integrity and nice of the pressure vessels. Ongoing education and skill development are critical to keeping up with the evolving industry requirements and technological improvements, ensuring that the craftsmanship no longer simplest meets but exceeds the present-day enterprise expectancies.

Table of Contents

ToggleRelated Blog Post

- Why are pressure vessels spherical?

- Why are pressure vessels cylindrical in shape?

- Why do pressure vessels have a hemispherical ends?

- What are the six case histories of pressure vessel failures?

- Which ASME code is used for pressure vessel design and fabrication?

- What is a good source of information for the design of pressure vessels?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.