The Importance of Pressure Vessel Material

Table of Contents

ToggleIntroduction to Pressure Vessel Material Significance

At Red River LLC, we understand that pressure vessels are greater than simply components; they are the coronary heart of many industries we proudly serve, inclusive of oil and gasoline, energy era, and biogas. These vessels, vital for containing gases or drinks at excessive pressures, are pivotal in operations ranging from strength manufacturing to mineral processing. Our dedication isn’t just to manufacture those vessels but to innovate and improve them, making sure they contribute appreciably to the industries that shape the backbone of our society.

Overview of Material Impact on Pressure Vessel Performance

Why does pressure vessel fabric count number? The solution lies within the core of our production philosophy. The desire for cloth directly influences the overall performance, protection, and longevity of pressure vessels. At Red River, we do not simply select materials; we pick out a promise of niceness and reliability. Whether it is coping with severe temperatures or corrosive substances, the right fabric ensures the most effective capability and safety. Our information in fabric choice isn’t always only a career; it is a commitment to excellence and a testomony to our dedication to the very best requirements of fine.

The Objective of This Guide

This manual is crafted to enlighten you about the significance of cloth choice in pressure vessels and to showcase how Red River LLC stands aside in this crucial issue. We goal to offer you insights to help you apprehend the important thing factors in choosing materials for pressure vessels, emphasizing our dedication to protection, best, and American values. We intend to be greater than a manufacturer; we try to be an associate who stocks your vision and values, ensuring that each pressure vessel we produce is a testament to our unwavering dedication to excellence.

The Role of Materials in Pressure Vessel Safety

Material Strength and Vessel Integrity

The strength of substances utilized in pressure vessels is paramount to ensuring vessel integrity. At Red River LLC, we meticulously pick out substances that withstand excessive pressures and pressures, safeguarding against capability ruptures or leaks. Our dedication to safety starts with deciding on strong substances that promise reliability underneath numerous operational conditions.

Corrosion Resistance and Material Longevity

The durability and performance of pressure vessels are considerably prompted by their corrosion resistance. We prioritize substances that endure harsh environments, maintaining their integrity through the years. This technique no longer guarantees safety however also optimizes the lifecycle of the vessels, offering lengthy-term value to our clients.

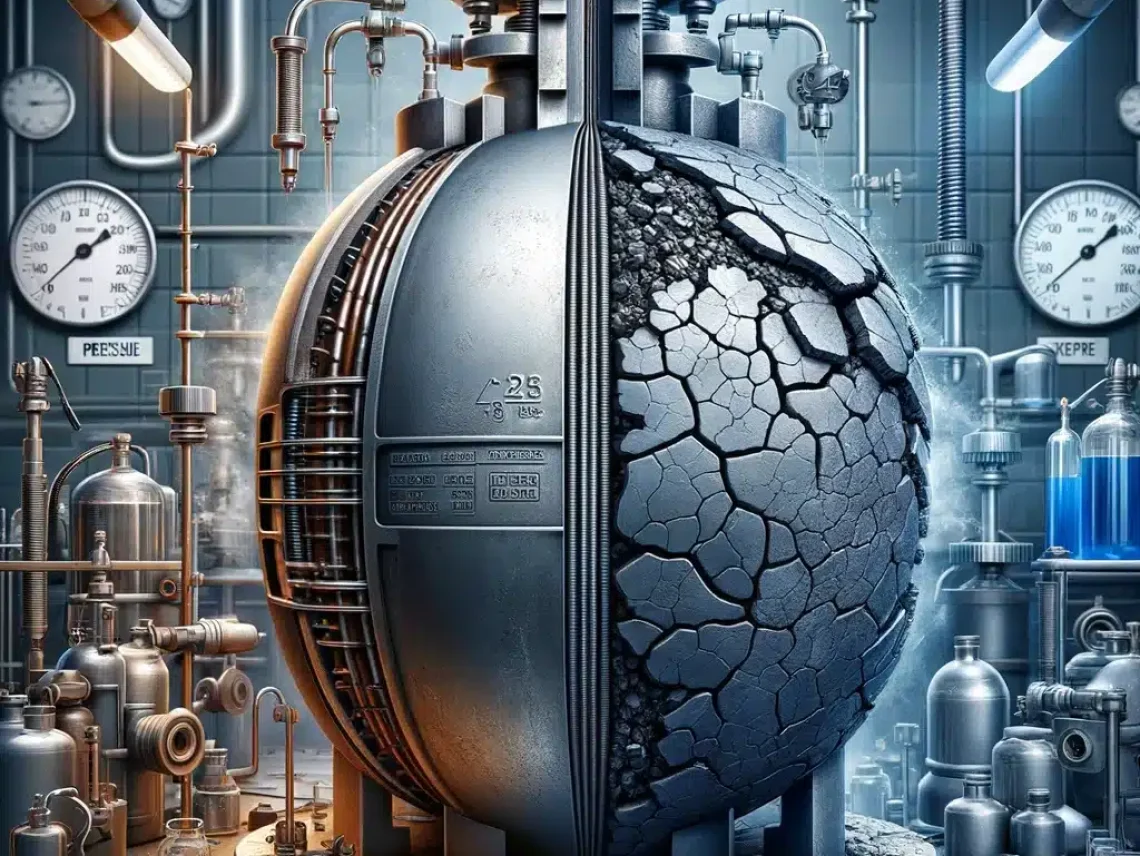

Case Studies: Material Failures and Successes

Our enjoyment is backed by way of mastering each success and disaster in material choice. We examine case research to continually refine our approach, ensuring that the training discovered is implemented to provide more secure, extra reliable pressure vessels.

Material Selection Criteria for Pressure Vessels

Analyzing Pressure and Temperature Requirements

Selecting the proper fabric for pressure vessels entails a radical evaluation of pressure and temperature requirements. Our crew at Red River LLC evaluates those elements to ensure that the chosen cloth no longer most effectively meets but exceeds the operational needs of the vessel.

Compatibility with Stored Media

The compatibility of materials with the stored media is essential. We check the chemical nature of the contents to ensure that the material decided on offers the most useful performance without compromising the vessel’s integrity or the purity of the contents.

Industry Standards and Compliance

Adherence to enterprise requirements and compliance is non-negotiable in our clothing choice procedure. We make certain that all substances meet or exceed ASME requirements, guaranteeing safety, great, and reliability in each pressure vessel we manufacture.

Impact of Material Properties on Vessel Design

How Material Affects Vessel Thickness and Weight

The desire for material immediately influences the design of pressure vessels, in particular in phrases of thickness and weight. Our engineering group skillfully balances those elements to optimize performance even as ensure safety and efficiency.

Material Flexibility and Fabrication Challenges

We remember the flexibility of substances and the related fabrication challenges. This method permits us to innovate in our production approaches, ensuring that even the most complex designs are realized without compromising on high quality.

Innovations in Material Technology

Staying abreast of innovations in material generation is prime to our success. We always include superior substances and strategies to enhance the performance and protection of our pressure vessels.

Key Factors in Choosing Materials for Durability

Assessing Environmental Factors

Environmental elements play a giant role in fabric selection for sturdiness. We examine conditions inclusive of exposure to elements and operational surroundings to make sure that our pressure vessels face up to take a look at time.

Long-term Performance Considerations

Our cognizance of long-term overall performance drives our clothing selection manner. We pick substances that now not only meet modern wishes but also anticipate destiny-demanding situations, ensuring lasting performance and reliability.

Maintenance and Inspection Requirements

We keep in mind the maintenance and inspection requirements of different materials, aiming to minimize downtime and make certain ease of preservation. This approach contributes to the general durability and fee effectiveness of our pressure vessels.

Cost-Benefit Analysis of Material Choices

Initial Investment vs. Long-Term Savings

When deciding on materials for pressure vessels, it is essential to take into account the trade-off between the preliminary funding and lengthy-term savings. At Red River LLC, we guide our clients through a comprehensive fee-benefit analysis, highlighting how the right fabric desire can result in huge savings over the lifespan of the vessel.

Material Availability and Sourcing Challenges

Material availability and sourcing demanding situations can affect each charge and undertaking timelines. Our group is nicely versed in navigating these problems, ensuring a clean procurement method whilst keeping expenses in take a look at.

Lifecycle Cost Analysis of Different Materials

We behavior thorough lifecycle value analyses of various materials, considering factors like preservation, repair, and alternative costs. This holistic technique permits us to advocate materials that provide the first-rate price over the years.

Regulatory and Compliance Aspects in Material Selection

Understanding ASME and International Standards

Compliance with industry requirements is paramount. We provide insights into ASME and international requirements, making sure that the materials decided on meet all important regulatory requirements, making sure safety and reliability.

Certification Requirements for Different Materials

Different substances come with diverse certification necessities. Our know-how in navigating those complexities guarantees that the selected materials meet all vital certifications, imparting peace of thought to our clients.

Navigating Global Compliance Variations

Global initiatives often involve versions of compliance necessities. We guide our clients via the maze of global compliance, ensuring that the materials selected are consistent with the specific rules of each assignment area.

Case Studies: Successful Material Applications in Pressure Vessels

Innovations in Steel and Alloy Use

We exhibit actual global case studies highlighting the successful use of progressive metal and alloy substances in pressure vessels. These examples show how the proper material picks can result in stepped-forward overall performance and safety.

Composite Materials and Future Trends

Explore case research that delves into the usage of composite substances in pressure vessels, dropping the light on destiny tendencies in cloth choice and their effect on vessel layout and performance.

Real-World Applications and Outcomes

Our case studies provide a glimpse into real-global packages of various materials in pressure vessels. These success memories underscore our dedication to locating fine fabric solutions for our customer’s unique desires.

The Future of Pressure Vessel Materials

Emerging Materials and Technologies

We discover the interesting world of emerging materials and technology, giving you insights into the future of pressure vessel materials. Stay ahead of the curve with our forward-wondering approach to material selection.

Sustainability and Eco-Friendly Materials

As sustainability becomes more and more important, we talk about how green substances are shaping the future of pressure vessels. Discover how those substances align with environmental desires while retaining protection and overall performance requirements.

Predicting Industry Trends and Changes

Our forward-searching attitude extends to predicting industry developments and changes in fabric possibilities. Stay informed about the evolving panorama of pressure vessel substances to make knowledgeable decisions for your projects.

Need a reliable partner?

Frequently Asked Questions (FAQs) About Pressure Vessel Materials

Why is the choice of material so crucial in pressure vessel manufacturing?

The preference of material for pressure vessels is essential because it directly impacts their protection, overall performance, and durability. Different substances have various strengths, corrosion resistance, and compatibility with saved media, making fabric choice a key element in making sure of the vessel’s reliability and toughness.

What factors should I consider when selecting materials for a pressure vessel?

When deciding on materials for a pressure vessel, remember elements just like the vessel’s operating pressure and temperature requirements, the character of the saved media, and enterprise requirements and compliance. These issues assist ensure that the selected substances meet the unique demands of your utility.

How does material selection affect the thickness and weight of a pressure vessel?

Material choice considerably affects the thickness and weight of a pressure vessel. Some substances can also require thicker partitions to withstand high pressures, at the same time as others provide electricity with thinner partitions. The desire for cloth also impacts the vessel’s weight, which may be vital for transportation and setup issues.

What are the benefits of prefabrication in pressure vessel manufacturing?

Prefabrication offers numerous benefits in pressure vessel production. It ensures regular satisfaction by using production additives in a controlled environment, lowering errors because of environmental conditions. Prefabrication also saves time by way of minimizing climate-related delays and streamlining fabric employers. Moreover, it could cause financial savings and stepped forward protection by way of lowering on-website publicity hours and related dangers.

What are the emerging materials and technologies in pressure vessel manufacturing?

The pressure vessel enterprise is witnessing innovations in substances and technology. Emerging substances, which include advanced alloys and composite materials, are providing improved overall performance and corrosion resistance. Additionally, advancements in fabric technology are bearing in mind more customization and efficiency in pressure vessel layout and fabrication.

Table of Contents

ToggleRelated Blog Post

- Why does a pressure vessel fail?

- What is the design pressure of a pressure vessel?

- What are the important points to be considered while designing a pressure vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.