Boilers and Pressure Vessels

Table of Contents

ToggleIntroduction to Boilers and Pressure Vessels

Boilers are more than just heating systems; in fact, they are the coronary heart of many industries, generating steam for strength and processing. At Red River, we fully understand the vital position boilers play in your operations, ensuring efficiency and reliability.

What is a Pressure Vessel?

Pressure vessels, often the unsung heroes of commercial protection and performance, are specialized bins designed to maintain gases or liquids at a pressure significantly different from the ambient pressure. Because of this critical function, our dedication to precision in pressure vessel manufacturing becomes even more essential, guaranteeing reliability where it matters most.

The Role of Boilers and Pressure Vessels in Industry

From oil and gas to biogas and advanced strength technology, boilers and pressure vessels play a pivotal role in numerous industries. At Red River, we are deeply committed to assisting these industries by leveraging our pinnacle-satisfactory manufacturing techniques and extensive knowledge of their unique requirements.

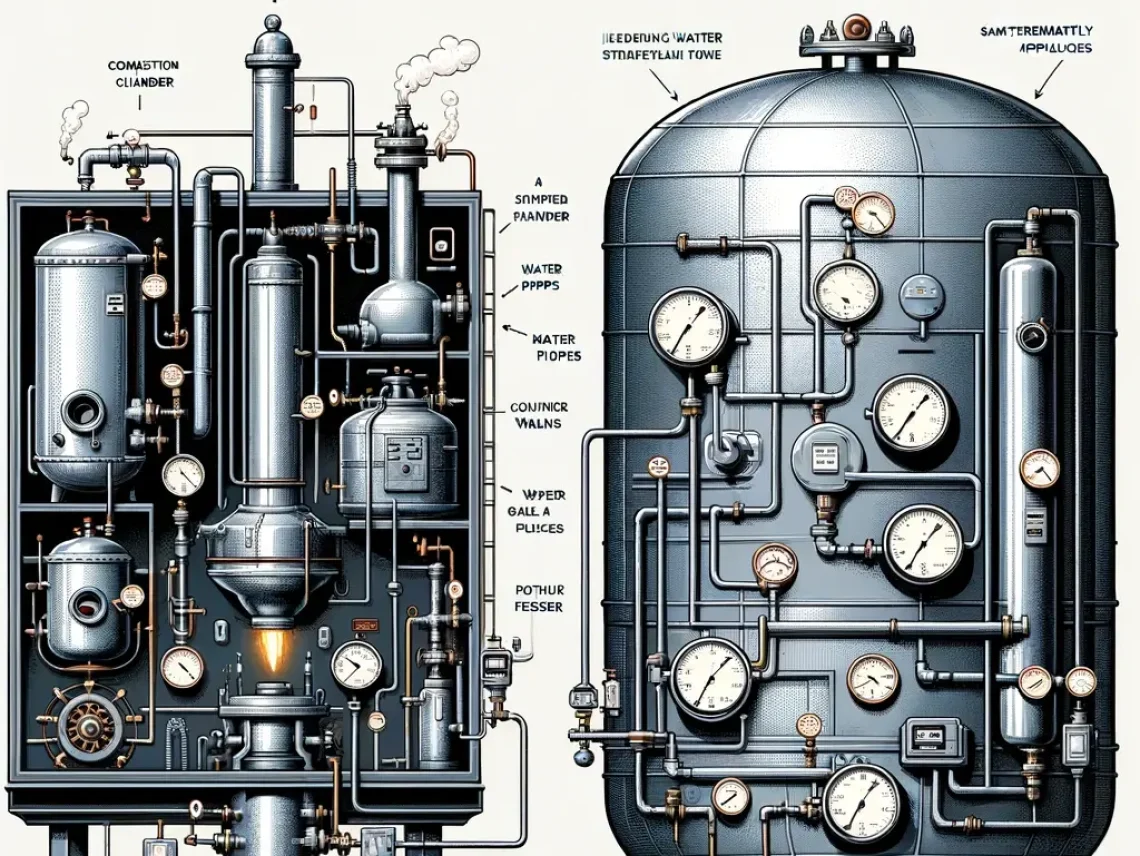

Key Differences Between Boilers and Pressure Vessels

Design and Construction Variations

At first glance, boilers and pressure vessels may seem quite similar. However, upon closer examination, their design and construction requirements are distinctly different. Because of these differences, our team at Red River excels in tailoring solutions to meet these precise specifications, ensuring maximum performance and safety.

Safety and Maintenance: Boilers vs. Pressure Vessels

Boiler Safety Protocols and Maintenance

At Red River, safety and performance remain our top priorities in boiler operations. To uphold these standards, we implement rigorous protection protocols designed to ensure long-term reliability and safety. By adhering to these measures, we help extend the operational lifespan of boilers while minimizing potential risks.

Need a reliable partner?

FAQs on Boilers and Pressure Vessels

What are the most essential elements to not forget whilst designing a pressure vessel for particular commercial programs?

When designing a pressure vessel for specific business applications, several key factors must be considered. These include the intended use, the type of substances it will contain, operating temperature and pressure, corrosion risks, and the surrounding environment. It is crucial to ensure the chemical compatibility of the materials with the vessel’s contents and their ability to expand or contract under thermal conditions. Additionally, the design must comply with industry regulations and standards, including ASME codes, to guarantee safety and functionality.

How do the preservation necessities vary between boilers and pressure vessels?

Boiler maintenance primarily focuses on ensuring efficient combustion, maintaining water chemistry, and preventing scale and corrosion, which can impact heat transfer and performance. Regular inspections help detect wear, leaks, or damage.

For pressure vessels, maintenance often involves routine inspections to check for pressure changes, corrosion, or structural damage. Technicians must ensure that safety valves and other components function correctly and that the vessel operates within its designated pressure range. Both boilers and pressure vessels require strict adherence to safety standards and protection protocols.

Can pressure vessels be custom-designed for unique applications, and what are the restrictions?

Yes, pressure vessels can be customized for specific applications. Customization options include size, shape, material composition, internal coatings, and specialized features such as nozzles and flanges.

However, limitations arise due to safety standards, material properties, and manufacturing feasibility. Custom designs must comply with regulatory standards, including ASME Boiler and Pressure Vessel Code, while material characteristics may also restrict customization possibilities.

What advancements in generation are presently impacting the design and efficiency of boilers and pressure vessels?

Recent advancements in boiler and pressure vessel design focus on high-energy, corrosion-resistant alloys and composite materials. There is also an increased reliance on computer-aided design (CAD) and 3D modeling for precision engineering.

For boilers, new technologies enhance heat transfer efficiency while reducing emissions. In pressure vessels, the integration of smart sensors and IoT technology enables real-time monitoring and predictive maintenance, improving safety and operational efficiency.

In what ways do environmental guidelines affect the construction and operation of boilers and pressure vessels?

Environmental regulations set emission limits, energy efficiency standards, and material disposal requirements, influencing boiler and pressure vessel design.

For boilers, compliance with NOx and CO₂ emission regulations affects fuel selection and combustion processes. In pressure vessels, environmental considerations impact material and coating choices, promoting sustainability while adhering to hazardous substance policies. Manufacturers must design equipment with minimal environmental impact, including safe decommissioning strategies to prevent long-term ecological damage.

Table of Contents

ToggleRelated Blog Post

- What is a forged pressure vessel?

- How do you design a pressure vessel?

- What is a pressure vessel also known as?

- What is the process of vessel fabrication?

- Which welding is used for pressure vessel?

- What is the most common design of pressure vessel?

- What are different methods used for fabrication of vessel explain it?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.