Table of Contents

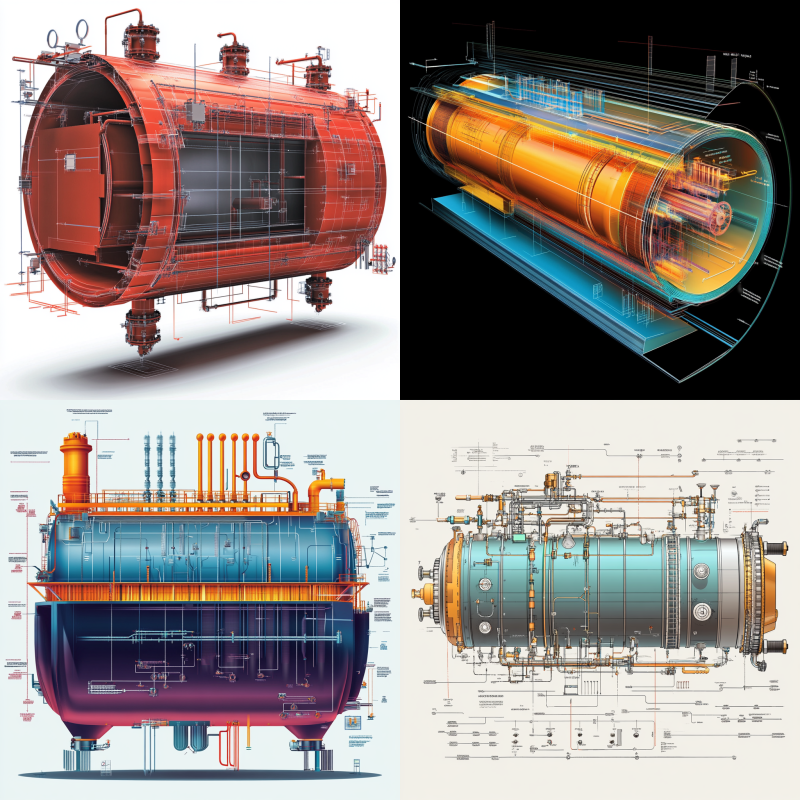

TogglePressure vessel wall thickness—including design thickness, nominal thickness, and effective thickness—is critical for safety and code compliance. According to ASME Section VIII, Division 1 (UG-27) and industry standards like API 650 and Eurocode EN 13445, engineers calculate minimum wall thickness based on internal pressure, vessel shape (cylindrical, spherical), material strength, and joint efficiency. This guide covers major methods, compares standards, and includes worked examples for different vessel types.

The pressure vessel thickness is influenced by several key factors that must be carefully considered in the design process. These include material selection, design pressure, corrosion, and compliance with safety standards.

Design Thickness: The sum of calculated minimum thickness plus corrosion allowance.

Nominal Thickness: The standardized thickness used for fabrication, rounded up from the design thickness.

Effective Thickness: The actual thickness available for pressure retention after subtracting corrosion and tolerances from the nominal thickness.

The type of material used for the pressure vessel significantly affects its thickness. Materials like steel, stainless steel, and aluminum each have unique properties that influence their ability to withstand pressure. For a detailed breakdown, see our guide on common pressure vessel materials

The design pressure is the maximum internal pressure that the pressure vessel is expected to handle. The higher the pressure, the thicker the vessel walls need to be to prevent failure.

Corrosion and wear are key factors that affect pressure vessel thickness over time. Adding a corrosion allowance ensures the vessel maintains its integrity throughout its operational lifespan.

Adhering to industry standards, such as the ASME Boiler and Pressure Vessel Code, is essential for determining the pressure vessel thickness. Learn more about our ASME-certified pressure vessel manufacturing process at Red River Team.

Standard | Use Case | Formula Emphasis | Notable Difference |

ASME VIII | General vessels | Internal pressure, joint efficiency | Applies to most vessel types |

API 650 | Storage tanks | Wind/seismic loads, shell stress | Specific to tanks/storage |

Eurocode | Europe (EN 13445) | Local stress, fatigue | Modern FEA integration |

Engineers calculate the required wall thickness using ASME UG-27 formulas. For cylindrical vessels under internal pressure:

t = (P × R) / (S × E – 0.6P)

Where:

t = required minimum thickness (inches or mm)

P = internal design pressure

R = inside radius of the vessel

S = maximum allowable stress for the material

E = weld joint efficiency

Spherical Vessel Example:

For a spherical vessel:

Use the formula: t = (P × R) / (2 × S × E – 0.2P)

(Insert numbers and solution as with the cylinder.)

Nominal Thickness Example:

If the calculated design thickness is 0.61 inches and corrosion allowance is 0.12 inches, round up to the nearest standard plate (say 0.75 in) for the nominal thickness.

Avoiding mistakes such as underestimating pressure requirements or ignoring material properties is crucial when designing for pressure vessel thickness. Accurate calculations are vital for safety.

Determining the correct pressure vessel thickness is essential for the vessel’s integrity and safety. By considering all relevant factors, engineers can ensure that the vessel is capable of withstanding internal pressures and operational stresses safely.

Want to grasp the fundamentals of pressure vessel engineering? Explore Understanding the Basics of Pressure Vessels on our blog to get started.

For professional assistance with pressure vessel design or to ensure your design meets the highest standards, contact Red River for expert guidance.

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

There is no single “standard” thickness. The required thickness depends on the internal pressure, material, and design codes. ASME provides detailed guidelines to calculate the required thickness based on these factors.

The thickness is calculated using formulas that take into account the internal pressure, radius of the vessel, material strength, and safety factors. Specialized software tools like FEA can be used for more complex designs.

ASME Section VIII does not define a single “minimum thickness.” Instead, it provides formulas (UG-27) to calculate thickness based on design pressure, radius, allowable stress, and joint efficiency.

UG-27 in the ASME Boiler and Pressure Vessel Code outlines the calculation methods for cylindrical and spherical shells. Engineers use this section to ensure vessels meet the minimum safety requirements.

Corrosion weakens pressure vessels over time, so an additional thickness is added to account for material loss, ensuring that the vessel remains safe throughout its lifespan.

Not meeting the required thickness can lead to catastrophic failure, including leaks, ruptures, or explosions, especially under high-pressure conditions.

Yes, spherical vessels typically require less thickness than cylindrical vessels for the same internal pressure due to the different stress distribution characteristics.

Add corrosion allowance to the calculated thickness, then round up to the nearest standard size.

ASME covers general vessels; API 650 is tailored to oil storage tanks with different load factors.

Spherical vessels need less wall thickness than cylindrical vessels under the same pressure, due to stress distribution.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.