Table of Contents

Toggle

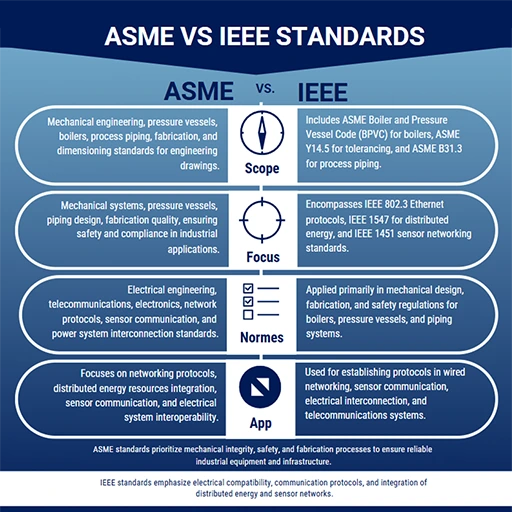

In the world of engineering, industry standards serve as the blueprint for innovation, safety, and consistency. Two of the most influential organizations behind these standards are the American Society of Mechanical Engineers (ASME) and the Institute of Electrical and Electronics Engineers (IEEE). While both are pillars in their respective fields, understanding the difference between ASME and IEEE is crucial for professionals navigating compliance, design, and technological development.

Whether you’re managing a multidisciplinary project or choosing the right professional path, this article will clarify the purpose, influence, and application of both organizations.

Founded in 1880, ASME is a nonprofit membership organization that sets internationally recognized codes and standards for mechanical engineering. What began as a response to boiler explosions in the 19th century has grown into a global authority on mechanical systems and safety.

ASME’s mission is to advance engineering for the benefit of humanity. It supports this mission through the development of over 500 codes and standards, continuing education, and publications.

ASME’s work primarily covers mechanical engineering fields, including:

These standards ensure that systems operate safely and efficiently, reducing the risk of catastrophic failures in industrial environments.

Among its most influential publications is the ASME Boiler and Pressure Vessel Code (BPVC). First issued in 1914, the BPVC sets the gold standard for the design, manufacture, and inspection of boilers and pressure vessels.

Today, many jurisdictions and organizations across the world mandate compliance with BPVC for safety and legal reasons. You can find more about BPVC at ASME’s official website.

ASME offers certification programs, technical journals, conferences, and access to engineering communities. Mechanical engineers benefit from networking and continuing education that directly aligns with the latest industry innovations.

Founded in 1963, IEEE is the result of a merger between the American Institute of Electrical Engineers (AIEE) and the Institute of Radio Engineers (IRE). It is now the world’s largest technical professional organization dedicated to advancing technology for the benefit of humanity.

IEEE’s mission focuses on fostering technological innovation and excellence. With over 400,000 members in more than 160 countries, IEEE is a global powerhouse in shaping the future of electrical and electronic technologies.

IEEE standards are essential in the following domains:

IEEE’s most recognized contributions include the IEEE 802 standards, such as 802.3 (Ethernet) and 802.11 (Wi-Fi), which serve as foundational technologies in networking.

You can explore IEEE’s complete standards at IEEE Standards Association.

IEEE publishes over 200 journals and magazines and organizes numerous conferences annually. It also offers certifications, research tools, and continuing education opportunities for engineers, academics, and industry professionals.

While the ASME B31.1 code is tailored for power piping, there are other codes within the ASME B31 series that serve different sectors.

ASME standards are heavily applied in physical systems—mechanical components, structural design, and safety protocols. In contrast, IEEE influences virtual and electronic infrastructures—networks, data systems, embedded software, and AI.

Many government and private institutions require ASME compliance for mechanical designs and products. Likewise, IEEE standards are adopted globally to ensure technological compatibility and performance, especially in telecommunications and IT.

Understanding when to apply ASME or IEEE standards depends on your project’s scope:

Projects like automated factory lines or smart HVAC systems require a fusion of both ASME and IEEE standards. ASME governs the mechanical and safety elements, while IEEE dictates control logic, communication, and interoperability.

If you’re leading a cross-functional team or managing a technical project, consult with domain-specific experts or trusted partners like Red River to ensure you’re using the right standard in every phase of your workflow.

Both ASME and IEEE have made monumental contributions to the engineering world, but they operate in distinctly different territories. ASME excels in setting the benchmark for mechanical systems and industrial safety, while IEEE is the backbone of electrical and digital innovation.

Whether you are designing a pressure vessel, implementing a smart grid, or building an AI-enabled product, the difference between ASME and IEEE standards will guide the structure, safety, and success of your solution.

Understanding how and when to apply each ensures compliance, reduces risks, and ultimately supports long-term innovation across industries.

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

The main difference is their focus. ASME deals with mechanical engineering and safety standards, while IEEE focuses on electrical, electronic, and computing technologies.

Yes. In projects involving mechanical and electronic components, both sets of standards may be necessary for safety and functionality.

In many jurisdictions, ASME standards are adopted into law for equipment design. IEEE standards are often required in IT, telecom, and consumer electronics.

ASME provides the definitive codes for pressure vessels through its Boiler and Pressure Vessel Code.

No. IEEE also addresses software development, computer engineering, AI, and power systems, among other fields.

Standards can be accessed through their respective websites: www.asme.org and www.ieee.org.

Yes. Both organizations have international reach, and their standards are widely respected and adopted globally.

It depends on your discipline. ASME is better suited for mechanical engineers, while IEEE is ideal for electrical, software, and computer engineers.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.