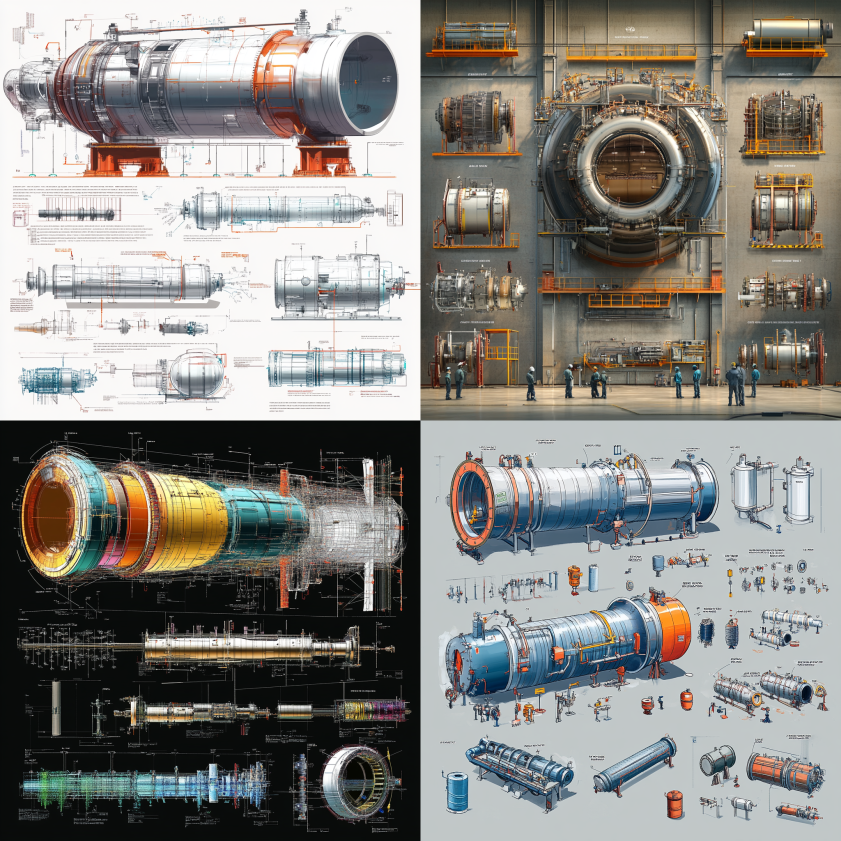

Pressure vessels are critical components across a wide range of industries—from energy and petrochemical plants to pharmaceuticals and food processing. These sealed containers, designed to hold gases or liquids at a pressure different from ambient conditions, must withstand tremendous internal and external stress. To ensure they do so safely and reliably, they are subject to rigorous inspection requirements defined by internationally recognized codes.

This is where the pressure vessel inspection code comes into play. These codes are not just regulatory checklists—they are essential frameworks for safety, quality assurance, and operational integrity. Whether you’re designing a new vessel, operating one in the field, or preparing for a compliance audit, understanding the relevant pressure vessel inspection code is vital.

At Red River LLC, we prioritize compliance, safety, and durability in every pressure vessel we design and fabricate. Let’s explore the key pressure vessel inspection code standards that govern this essential aspect of industrial operations.

Several established codes provide detailed standards for the inspection, testing, and maintenance of pressure vessels. Here are the most authoritative and widely used ones:

The ASME BPVC is the foundational pressure vessel inspection code for pressure vessels in the United States and many other countries. Developed by the American Society of Mechanical Engineers, it defines the rules for the design, fabrication, and inspection of boilers and pressure vessels.

This section is especially important as it covers unfired pressure vessels and is the most commonly used part of the code. It includes:

Vessels built under ASME Section VIII must be inspected by an Authorized Inspector (AI) during various fabrication stages. Upon successful completion, they receive an ASME “U” stamp, signifying compliance. Learn more about ASME Section VIII

While ASME governs the construction phase, the NBIC focuses on what happens next—installation, inspection, repairs, and alterations.

Managed by the National Board of Boiler and Pressure Vessel Inspectors, the NBIC includes:

The NBIC supports the pressure vessel inspection code framework from fabrication through end-use. Explore NBIC details

Created by the American Petroleum Institute, API 510 is a widely used pressure vessel inspection code in oil and gas, chemical processing, and energy sectors. This standard emphasizes:

Unlike ASME, which is primarily for new vessel construction, API 510 focuses on pressure vessels already in operation. Access API 510 guidelines

Pressure vessel inspections aren’t one-time events. They occur at multiple stages throughout the vessel’s lifecycle. Here’s a breakdown:

Modern pressure vessel inspections utilize a mix of visual and technical evaluations.

Common techniques include:

These tests are typically conducted by certified inspectors with qualifications from organizations like API, NBIC, or regional authorities.

Inspection codes aren’t just technical guidelines—they carry legal and safety implications.

In some jurisdictions, operating a pressure vessel without valid certification may even be a criminal offense. That’s why partnering with experienced fabricators and certified inspectors is essential.

At Red River LLC, we ensure all our vessels meet or exceed these regulatory standards—whether they’re being newly fabricated or returned for inspection or repair.

Inspection codes are the backbone of safety and quality in pressure vessel operations. From ASME Section VIII to API 510, these codes ensure that pressure vessels are designed, built, and maintained to perform under extreme conditions without compromising safety.

Understanding and applying the correct pressure vessel inspection code isn’t optional—it’s a legal and moral responsibility. Whether you’re operating a refinery, food processing plant, or power station, your pressure vessels must meet stringent inspection standards.

If you’re unsure about which code applies to your project, consult with certified professionals like those at Red River. We bring years of expertise and code compliance to every project.

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

The ASME BPVC Section VIII provides the standards for the design, construction, and inspection of unfired pressure vessels.

API 510 governs the in-service inspection, repair, alteration, and rerating of pressure vessels and focuses on continued safe operation.

Typically, external inspections are required every 5 years, and internal inspections based on operating conditions and risk assessments. API 510 provides detailed guidance on setting intervals.

The National Board Inspection Code outlines procedures for inspection, repair, and alteration of pressure-retaining items post-installation. It ensures continuity between fabrication and operational maintenance.

Only inspectors certified by API (e.g., API 510) or commissioned by the National Board (NBIC) are authorized to perform pressure vessel inspections.

The vessel must be repaired, rerated, or retired. Continuing operation without addressing failures can result in safety hazards, legal penalties, or operational shutdowns.

In most regions, no. ASME certification is a legal requirement and ensures structural integrity and compliance.

Yes. While ASME and NBIC are standards across industries, sectors like oil and gas often supplement them with API codes specific to their operational demands.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.