Table of Contents

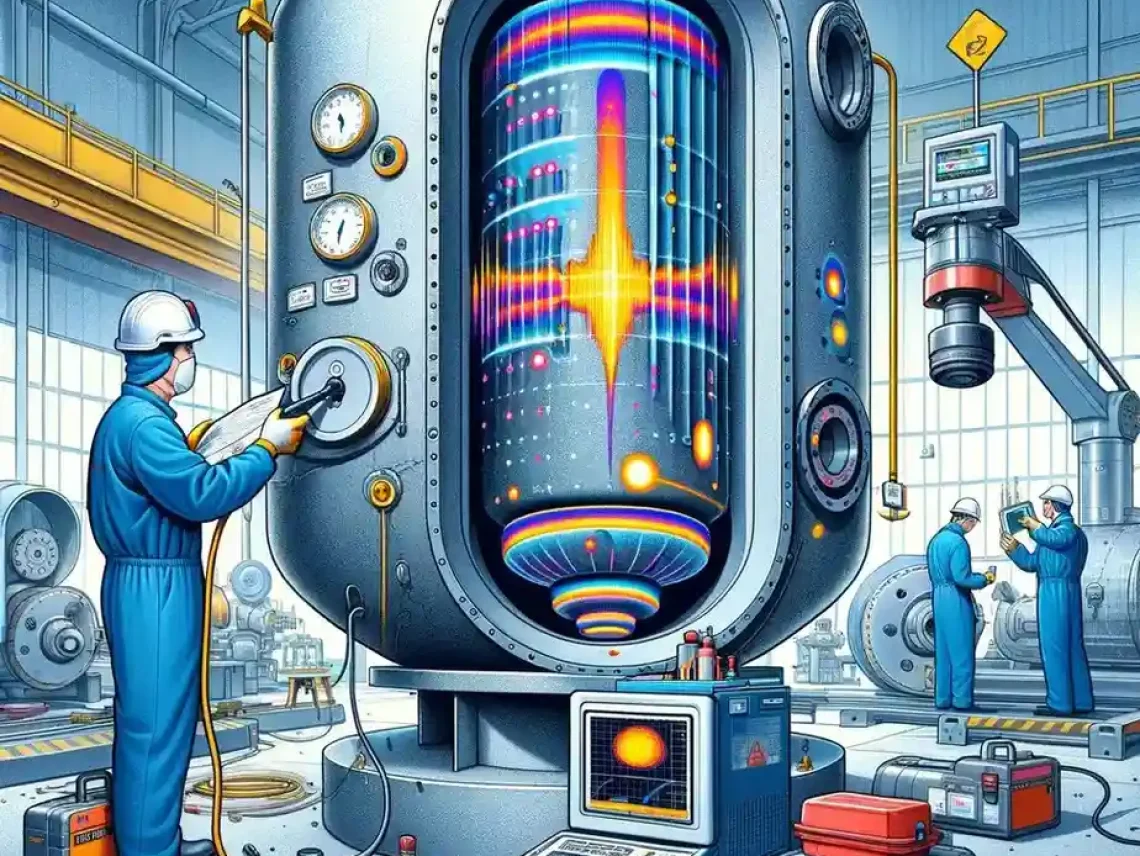

ToggleAt Red River LLC, we understand that the integrity of a pressure vessel is paramount. That’s why we appoint superior Non-Destructive Testing (NDT) strategies in our fabrication method. Our meticulous method to NDT is the spine of our commitment to delivering pressure vessels that now not simplest meet but exceed industry requirements. We’re now not simply fabricating vessels; we’re engineering protection and reliability into each project.

Safety and nice aren’t just buzzwords at Red River; they’re the core principles guiding our every action. By integrating Non-Destructive Evaluation into our fabrication process, we make certain every vessel is a testomony to our unwavering commitment to these principles. Our NDT practices are meticulously designed to come across even the smallest imperfections, making sure every vessel adheres to the very best protection and great standards.

Ultrasonic Testing (UT) is a cornerstone of our NDT procedure. This contemporary method allows us to discover subsurface flaws with extraordinary precision. At Red River, UT isn’t only a manner; it is an assurance of best and safety, making sure that every pressure vessel is powerful and reliable.

We appoint Radiographic Testing (RT) to offer a comprehensive inner exam of our pressure vessels. This advanced technique guarantees internal integrity, giving our customers the confidence that their vessels can face up to even the most worrying situations.

Surface integrity is important, and our Magnetic Particle Testing (MPT) is designed to ensure simply that. This technique allows us to discover floor and close-to-floor discontinuities, ensuring that every inch of the vessel meets our stringent exceptional standards.

Preparation is key in NDT. At Red River, we meticulously prepare every vessel for trying out, making sure that our NDT tactics are as accurate and effective as viable. This guidance is a vital step in our promise to deliver vessels of unequaled high quality and safety.

Our NDT inspections are thorough and systematic. We comply with a step-by-step process that ensures each potential issue is diagnosed and addressed. Our crew of professionals is skilled to conduct these inspections with precision and care, leaving no stone unturned in our quest for excellence.

Interpreting NDT effects is an art, and our experts are masters of it. We do not simply become aware of capability troubles; we understand their implications and take proactive steps to deal with them. This technique is fundamental to our dedication to turning in vessels that are secure, reliable, and of the best fine.

Adherence to ASME and different global standards isn’t always pretty much compliance for us at Red River; it’s about a dedication to excellence. Our NDT practices are rigorously aligned with these requirements, ensuring every vessel we produce is a benchmark within the enterprise.

Compliance and certification in NDT are non-negotiable at Red River. We ensure that each technician is not best certified however additionally embody our ethos of continuous getting to know and improvement. This dedication to excellence in NDT practices is contemplated inside the unheard-of nice of our vessels.

We’re at the leading edge of incorporating innovations like Phased Array Ultrasonic Testing (PAUT). This superior technique lets us offer greater specified and accurate inspections, reinforcing our promise of delivering vessels that set industry benchmarks in protection and satisfaction.

Embracing destiny, we utilize Digital Radiography (DR) in our trying-out approaches. This not simplest enhances the precision of our inspections but additionally extensively reduces turnaround instances, ensuring that our customers obtain their pressure vessels quicker, without compromising on satisfaction or protection.

Our portfolio is filled with success testimonies in which NDT performed a pivotal position in ensuring vessel integrity. From complex industrial applications to critical strength projects, our NDT understanding has been a cornerstone in handing over successful results.

Each task brings its specific demanding situations, and we’ve found treasured training from using NDT in complicated fabrication scenarios. These reports have not only refined our techniques but also deepened our know-how of pressure vessel integrity in numerous programs.

At Red River, we firmly accept as true that NDT isn’t always just a testing technique, but a critical device in making sure the maximum safety of our pressure vessels. Our rigorous NDT procedures without delay impact and enhance vessel protection, providing peace of mind to our clients.

Our exceptional metrics in pressure vessel fabrication are extensively encouraged by our NDT procedures. We set high standards, and NDT facilitates us no longer simply to fulfill them but regularly to exceed them, ensuring every vessel is a symbol of excellence.

Training and certification for our NDT technicians at Red River are paramount. We spend money on their non-stop education and ability enhancement, making sure they are not just qualified but excel in their field. This dedication to education is a cornerstone of our potential to deliver top-tier pressure vessels.

Innovation and non-stop development in NDT methods are part of our subculture at Red River. We are continually searching out methods to strengthen our strategies, ensuring we live on the slicing fringe of generation. This ongoing pursuit of excellence is reflected in the advanced quality and protection of our pressure vessels.

At Red River, we keep an eager eye on rising technology in NDT. We apprehend that staying ahead of the curve is important for retaining our leadership within the industry. Our dedication to adopting new technology ensures that we continue to offer our customers exceptional pressure vessel fabrication.

Understanding and predicting tendencies in pressure vessel trying out and safety permit us to assume the destiny needs of the enterprise. At Red River, we do not just react to adjustments; we proactively form our strategies to live ahead of enterprise tendencies, ensuring our customers continually get hold of brand-new answers.

Selecting the right NDT issuer is crucial to your pressure vessel assignment. At Red River, we offer a blend of experience, technology, and a dedication to exceptional that sets us apart. Our crew isn’t always simply providing a provider; we are your companions in ensuring the success of your undertaking.

Choosing Red River LLC approach opting for a partner with extraordinary expertise in pressure vessel NDT. Our aggregate of seasoned specialists, current era, and deep-rooted dedication to safety best make us the suitable choice for your pressure vessel desires.

Non-Destructive Testing plays a critical role in ensuring the safety and integrity of pressure vessels. It allows for the thorough examination of materials, components, and constructions without causing damage. This is essential for detecting potential defects or weaknesses that could lead to failures under pressure, ensuring that the vessels meet stringent safety standards.

By detecting flaws and inconsistencies early in the fabrication process, NDT helps in addressing issues before they escalate into major problems. This proactive approach not only enhances the safety of the vessels but also contributes to their longevity and reliability, as potential weak points are identified and strengthened during the manufacturing process.

Yes, there are several NDT methods, including Ultrasonic Testing (UT), Radiographic Testing (RT), and Magnetic Particle Testing (MPT). The choice of method depends on the material of the vessel, the type of construction, and the specific requirements of the project. Factors like accessibility, the size of the vessel, and the nature of the potential defects play a role in determining the most suitable NDT method.

While NDT is highly effective in detecting a wide range of defects, its efficacy can vary depending on the type of defect and the method used. Some methods are better suited for detecting surface flaws, while others are more effective for internal inconsistencies. It’s important to choose the right NDT technique based on the expected type of defects and the physical properties of the vessel.

NDT methods are designed to comply with industry standards and regulations, such as those set by the American Society of Mechanical Engineers (ASME). These standards ensure that the testing is thorough, accurate, and capable of detecting defects that could compromise the safety and functionality of the pressure vessel. Compliance with these standards is crucial for ensuring that the fabricated vessels are safe for use and meet the required legal and safety obligations.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.