Determining the Minimum Thickness for a Pressure Vessel

Introduction to what is the minimum thickness for a pressure vessel

Pressure vessels are integral components in various industries, serving to store and transport gases or liquids at different pressures and temperatures. Ensuring the safety and efficiency of these vessels is paramount. One critical aspect of pressure vessel design is determining the minimum thickness required to withstand the internal pressure and external loads. In this article, we will delve into the factors that influence the minimum thickness of a pressure vessel and the methods used to calculate it.

Factors Influencing Minimum Thickness

Several factors play a crucial role in determining the minimum thickness of a pressure vessel:

Internal Pressure:

The primary factor affecting minimum thickness is the internal pressure the vessel is expected to contain. Higher pressures necessitate thicker walls to prevent structural failure. Engineers calculate the required thickness by considering the material’s tensile strength and the design pressure.

Material Properties:

The choice of material is pivotal. Different materials have varying tensile strengths and corrosion resistance properties. Stainless steel, carbon steel, and unfamiliar alloys are common choices. Engineers must select a material that can withstand the vessel’s operating conditions.

Design Code and Standards:

Pressure vessels must adhere to industry-specific design codes and standards, such as ASME (American Society of Mechanical Engineers) Boiler and Pressure Vessel Code or API (American Petroleum Institute) standards. These codes provide guidelines for determining minimum thickness based on factors like safety margins, material properties, and intended use.

Temperature:

Temperature fluctuations can affect a pressure vessel’s minimum thickness. High temperatures can reduce the material’s strength, necessitating thicker walls to compensate.

Corrosion Allowance:

Engineers often include a corrosion allowance in their calculations. This extra thickness accounts for potential material loss due to corrosion over the vessel’s lifespan.

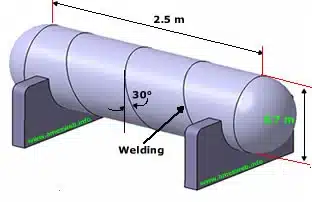

Welding Considerations:

The method and quality of welding also impact minimum thickness. Welding introduces additional stress points, so engineers must account for this in their calculations.

Methods for Calculating Minimum Thickness

Barlow's Formula:

Barlow’s formula is a common method for calculating the minimum thickness of a pressure vessel’s cylindrical shell. It is based on the hoop stress and the design pressure. The formula is as follows:

Minimum Thickness (t) = (P * D) / (2 * S * E)

Where:

- t = Minimum thickness

- P = Design pressure

- D = Internal diameter of the vessel

- S = Allowable stress of the material

- E = Weld efficiency factor

Finite Element Analysis (FEA):

FEA is a more advanced technique that involves computer simulations to model the behavior of a pressure vessel under various conditions. FEA provides a more precise estimation of minimum thickness by considering complex geometries and stress distribution.

Industry Standards:

Engineers often rely on industry-specific standards and codes to determine minimum thickness. These standards provide comprehensive guidelines and equations to ensure safety and compliance.

In addition to determining the minimum thickness of a pressure vessel, engineers must take several other factors into account to ensure the vessel’s integrity and safety:

Head Design:

Pressure vessels often have heads at both ends. The design of these heads, whether hemispherical, ellipsoidal, or flat, must meet specific standards and calculations. The thickness of the heads is a critical consideration in overall vessel design.

Nozzle Design:

Nozzles are openings in the pressure vessel through which fluids enter or exit. Proper nozzle design and reinforcement are crucial to prevent stress concentrations and ensure structural integrity.

Supports and Attachments:

Pressure vessels are typically supported by various structural components, such as skirts, saddles, or legs. The design of these supports must distribute the vessel’s weight and external loads evenly to prevent deformation or stress concentration.

Pressure Relief Devices:

To prevent overpressure and potential catastrophic failure, pressure vessels are equipped with pressure relief devices, such as safety valves. The sizing and placement of these devices are vital in ensuring the vessel’s safety.

Material Selection:

The choice of material is not limited to its strength alone but also factors in aspects like corrosion resistance, cost, and availability. The material must be compatible with the stored fluid and operating conditions.

Quality Control and Inspection:

Stringent quality control measures and regular inspections are essential throughout the pressure vessel’s lifecycle. This helps detect signs of corrosion, wear, or fatigue that may affect the vessel’s minimum thickness and overall safety.

Fatigue Analysis:

Over time, pressure vessels may experience cyclic loading due to fluctuations in pressure and temperature. Engineers perform fatigue analysis to ensure that the vessel can withstand these cyclic stresses without failure.

Code Compliance:

Compliance with industry standards and codes is non-negotiable. Failure to adhere to these codes can result in legal ramifications and, more importantly, jeopardize safety.

Maintenance and Inspection for Pressure Vessels

Maintenance and Inspection for Pressure Vessels

Once a pressure vessel is designed and constructed to meet the required minimum thickness and other safety standards, it’s crucial to establish a robust maintenance and inspection program to ensure its continued safe operation. Regular inspection and maintenance activities help identify potential issues early, preventing accidents and costly repairs or replacements.

Regular Inspections:

Pressure vessels should undergo periodic inspections by qualified personnel. These inspections include visual examinations, non-destructive testing (NDT) techniques like ultrasonic testing, radiography, and magnetic particle testing, as well as stress analysis. The frequency of inspections depends on factors such as the vessel’s operating conditions, contents, and regulatory requirements.

Corrosion Monitoring:

Corrosion is a common issue in pressure vessels, and it can lead to a reduction in minimum thickness over time. Monitoring the internal and external surfaces for signs of corrosion is crucial. Corrosion protection methods such as coatings, cathodic protection, and corrosion inhibitors may be employed.

Pressure Relief Device Testing:

The pressure relief devices, including safety valves and rupture discs, must be tested and calibrated regularly to ensure they function correctly. Properly functioning relief devices are essential for preventing overpressure incidents.

Fitness-for-Service Assessment:

Engineers may conduct fitness-for-service (FFS) assessments to evaluate the continued safe operation of a pressure vessel that may have experienced damage or deterioration. FFS assessments help determine if the vessel can continue to operate within specified safety margins.

Repair and Replacement:

If inspections reveal significant corrosion, defects, or damage that affect the minimum thickness or overall structural integrity, repairs or replacement may be necessary. These activities should be carried out in strict accordance with industry standards and codes.

Record Keeping:

Maintaining detailed records of inspections, repairs, and maintenance activities is essential for regulatory compliance and ensuring a complete history of the vessel’s condition.

Emergency Response Plan:

Having a well-defined emergency response plan in place is crucial in case of unexpected incidents. This plan should include procedures for shutdown, isolation, and evacuation, as well as communication protocols with emergency services.

Training and Certification:

Personnel responsible for inspecting, maintaining, and operating pressure vessels should be properly trained and certified. They should have a deep understanding of the vessel’s design, operating conditions, and safety protocols.

Environmental Considerations:

Pressure vessel operators must also consider environmental factors, such as emissions control and waste disposal, to ensure compliance with environmental regulations.

Pressure Vessel Safety and Industry Advancements

As technology and industry standards continue to evolve, so too does the field of pressure vessel safety. Here are some advancements and best practices that contribute to the ongoing improvement of pressure vessel safety:

Advanced Materials:

The development of new materials with enhanced strength, corrosion resistance, and durability has expanded the options for pressure vessel construction. These materials often allow for more efficient designs and longer service life.

Finite Element Analysis (FEA):

FEA has become an indispensable tool for designing and analyzing pressure vessels. It enables engineers to simulate complex stress distributions, fatigue, and other critical factors, leading to more accurate designs and improved safety margins.

Smart Sensors and Monitoring:

The integration of smart sensors and real-time monitoring systems allows for continuous data collection and analysis of pressure vessel conditions. Any deviations or anomalies can be detected and addressed promptly, reducing the risk of unexpected failures.

3D Printing:

Additive manufacturing, or 3D printing, is being explored for producing pressure vessel components with complex geometries. This technology can offer advantages in terms of weight reduction and customization.

High-Performance Coatings:

Advanced coatings and surface treatments provide added protection against corrosion, extending the life of pressure vessels and reducing maintenance requirements.

Risk-Based Inspection:

Rather than relying on fixed inspection intervals, risk-based inspection (RBI) assesses the specific risks associated with each pressure vessel and tailors inspection schedules accordingly. This approach optimizes resource allocation and enhances safety.

International Collaboration:

As industries become increasingly globalized, international collaboration on pressure vessel safety standards and practices helps ensure consistency and best practices worldwide.

Automation and AI:

Artificial intelligence (AI) and automation are being applied to data analysis, predictive maintenance, and even the design of pressure vessels. These technologies can improve efficiency and reduce human error.

Environmental Sustainability:

Pressure vessel design and operation are also influenced by a growing focus on environmental sustainability. Companies are exploring ways to reduce energy consumption, emissions, and waste in their processes, which can impact pressure vessel requirements and design.

Safety Culture:

Safety culture within organizations plays a significant role in pressure vessel safety. Companies that prioritize safety training, communication, and a culture of reporting and learning from near-miss incidents are more likely to prevent accidents.

Challenges and Future Directions in Pressure Vessel Safety

While significant progress has been made in pressure vessel safety, several challenges and future directions are worth considering:

Harsh Environments:

Industries such as oil and gas exploration, chemical processing, and aerospace often operate in extreme and corrosive environments. Developing pressure vessels that can withstand these conditions while maintaining safety is an ongoing challenge.

Aging Infrastructure:

Many pressure vessels in use today are decades old. Managing and ensuring the safety of aging infrastructure poses unique challenges, including assessing the impact of corrosion and fatigue over extended service lives.

Hydrogen Storage:

With the growing interest in hydrogen as a clean energy carrier, there is a need for innovative pressure vessel designs that can safely store and transport hydrogen gas, which has unique challenges due to its high diffusivity and potential for embrittlement.

Miniaturization:

In some applications, pressure vessels need to be miniaturized while maintaining safety standards. These micro- or nano-scale vessels present unique challenges in design, manufacturing, and inspection.

Hybrid Materials:

The use of hybrid materials, such as composites reinforced with nanoparticles, presents both opportunities and challenges. These materials offer benefits like reduced weight and increased strength but require careful evaluation of their behavior under pressure.

Cybersecurity:

As pressure vessel monitoring and control systems become more interconnected and reliant on digital technology, there is a growing need to address cybersecurity risks to prevent unauthorized access or tampering with critical systems.

Regulatory Changes:

Regulatory bodies are continually updating standards and codes to reflect new technologies and safety best practices. Keeping up with these changes and ensuring compliance is an ongoing challenge for industries.

Environmental Impact:

The pressure vessel industry is under increasing pressure to reduce its environmental footprint. This includes considerations such as reducing emissions during manufacturing, improving recycling of materials, and exploring more sustainable alternatives.

Education and Training:

Ensuring that engineers and operators have access to comprehensive education and training programs is essential for maintaining a high level of safety. This includes training on new technologies and safety practices.

Globalization:

As industries expand globally, pressure vessel safety standards need to be harmonized across different regions to ensure consistency and minimize the risk of accidents.

The Future of Pressure Vessel Safety: Innovations and Trends

As we look ahead, pressure vessel safety is poised to benefit from several key innovations and emerging trends. These developments aim to enhance safety, efficiency, and sustainability in various industries that rely on pressure vessels:

Advanced Materials:

Continued research into advanced materials, including high-strength alloys, composites, and nanomaterials, will result in pressure vessels that are not only stronger but also more lightweight, leading to improved energy efficiency and reduced environmental impact.

Smart Sensors and IoT Integration:

The integration of smart sensors and the Internet of Things (IoT) technology will enable real-time monitoring of pressure vessel conditions. Data analytics and machine learning algorithms will provide predictive maintenance insights, helping prevent failures before they occur.

Digital Twins:

Digital twins, virtual replicas of physical pressure vessels and their operating conditions, will become more prevalent. They enable engineers to simulate and analyze how pressure vessels behave under various scenarios, optimizing designs and predicting potential issues.

Additive Manufacturing:

Additive manufacturing, also known as 3D printing, will continue to play a growing role in pressure vessel manufacturing. This technology allows for intricate geometries, customization, and rapid prototyping while ensuring structural integrity.

Hybrid Pressure Vessels:

The development of hybrid pressure vessels that combine traditional materials with advanced composites and nanomaterials will offer superior performance in terms of weight reduction, corrosion resistance, and improved safety margins.

Circular Economy Principles:

Industries will increasingly adopt circular economy principles, emphasizing the reuse, recycling, and repurposing of pressure vessel materials to reduce waste and environmental impact.

Hydrogen Storage Advancements:

As hydrogen gains prominence as a clean energy carrier, innovations in pressure vessel design and materials will be critical for safe and efficient hydrogen storage and transportation.

Simulation and Modeling:

Advanced computational tools and simulation software will become more accessible, allowing engineers to conduct detailed stress analysis, fatigue modeling, and failure prediction with greater accuracy.

Global Standards Harmonization:

Efforts to harmonize pressure vessel safety standards and codes globally will continue, making it easier for companies to operate internationally while maintaining safety compliance.

Training and Certification:

Enhanced training programs and certification processes for engineers, inspectors, and operators will ensure that individuals involved in pressure vessel safety have up-to-date knowledge and skills.

Environmental Regulations:

Stricter environmental regulations will influence pressure vessel design and operation, with a focus on reducing emissions, energy consumption, and waste generation.

Green Technologies:

The development of green technologies, such as hydrogen fuel cells and carbon capture and storage, will drive innovation in pressure vessel design for sustainable energy applications.

In conclusion, the future of pressure vessel safety is marked by a combination of technological advancements, regulatory changes, and a commitment to sustainability. These trends and innovations will collectively contribute to the continued improvement of pressure vessel safety across various industries, safeguarding lives, assets, and the environment. Staying informed and adapting to these changes will be essential for organizations and professionals involved in pressure vessel design, operation, and maintenance.

Need a reliable partner?

FAQs about Minimum Thickness for Pressure Vessels

What is the minimum thickness requirement for a pressure vessel?

The minimum thickness for a pressure vessel depends on several factors, including the material of construction, the design pressure, and the type of fluid it will contain. Generally, thickness is determined following applicable design codes and standards, such as ASME Boiler and Pressure Vessel Code. It’s crucial to engage with a qualified engineer or pressure vessel designer to ensure compliance with safety regulations and specific project requirements.

The minimum thickness varies, but it is typically calculated using the formulas provided in the relevant design codes, considering factors like material properties, design pressure, and safety margins. Engaging with an experienced engineer during the design phase ensures compliance with industry standards and safety protocols.

How does material selection impact the minimum thickness of a pressure vessel?

Material selection plays a significant role in determining the minimum thickness of a pressure vessel. Different materials have varying mechanical properties, such as yield strength and corrosion resistance, which directly influence the required thickness for structural integrity.

Materials with higher yield strength may allow for a reduction in thickness, while factors like corrosion susceptibility might necessitate a thicker wall. A careful consideration of material properties ensures that the pressure vessel meets safety standards and project-specific requirements.

Can the minimum thickness of a pressure vessel be determined without following specific design codes?

While it’s possible to estimate thickness informally, adhering to established design codes is crucial for ensuring the structural integrity and safety of pressure vessels. These codes provide standardized methodologies and safety margins essential for compliance with industry standards.

Following specific design codes is highly recommended, as they incorporate extensive research and engineering practices to establish safe thickness requirements. Deviating from these codes may compromise the integrity of the pressure vessel and pose potential safety risks.

How does the type of fluid affect the minimum thickness of a pressure vessel?

The nature of the fluid the pressure vessel will contain can impact the minimum thickness requirements. Factors such as temperature, corrosiveness, and potential reactivity with the vessel material must be considered to ensure long-term reliability.

Corrosive or reactive fluids may necessitate thicker vessel walls to withstand their effects over time. Temperature extremes can also influence material properties, requiring adjustments to the minimum thickness to maintain structural integrity under varying conditions.

Are there industry-specific considerations for determining the minimum thickness of pressure vessels?

Yes, different industries may have specific requirements and considerations when determining the minimum thickness of pressure vessels. For example, the petrochemical industry might have different criteria than the pharmaceutical industry due to variations in operating conditions and safety standards.

Industry-specific guidelines and regulations often exist to address unique challenges and hazards. Adhering to these specific requirements ensures that pressure vessels are designed to withstand the conditions relevant to their intended applications, promoting safety and reliability.

Related Blog Post

- What is a pressure vessel API?

- How do you test a pressure vessel?

- How do you size a pressure vessel?

- What pressure should a pressure vessel be?

- What is the ISO standard for pressure vessels?

- How is thickness of a pressure vessel calculated?

- Which software is used for pressure vessel design?

- What is the minimum thickness for a pressure vessel?

- What is the difference between a vessel and a pressure vessel?

- What is the difference between vertical and horizontal pressure vessels?

- What is the difference between open end and closed end pressure vessels?

- What is the difference between a pressure vessel and a high pressure vessel?

- Are pipes considered pressure vessels?

- Do I need a pressure vessel?

- What is the ASME definition of a pressure vessel?

- What are the dangers of high pressure vessels?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No pillar keyword set for this post.

About Author