Exploring Cryogenic Liquid Tank Venting: Understanding Normality

Table of Contents

ToggleWhat is Venting and Why Does it Occur?

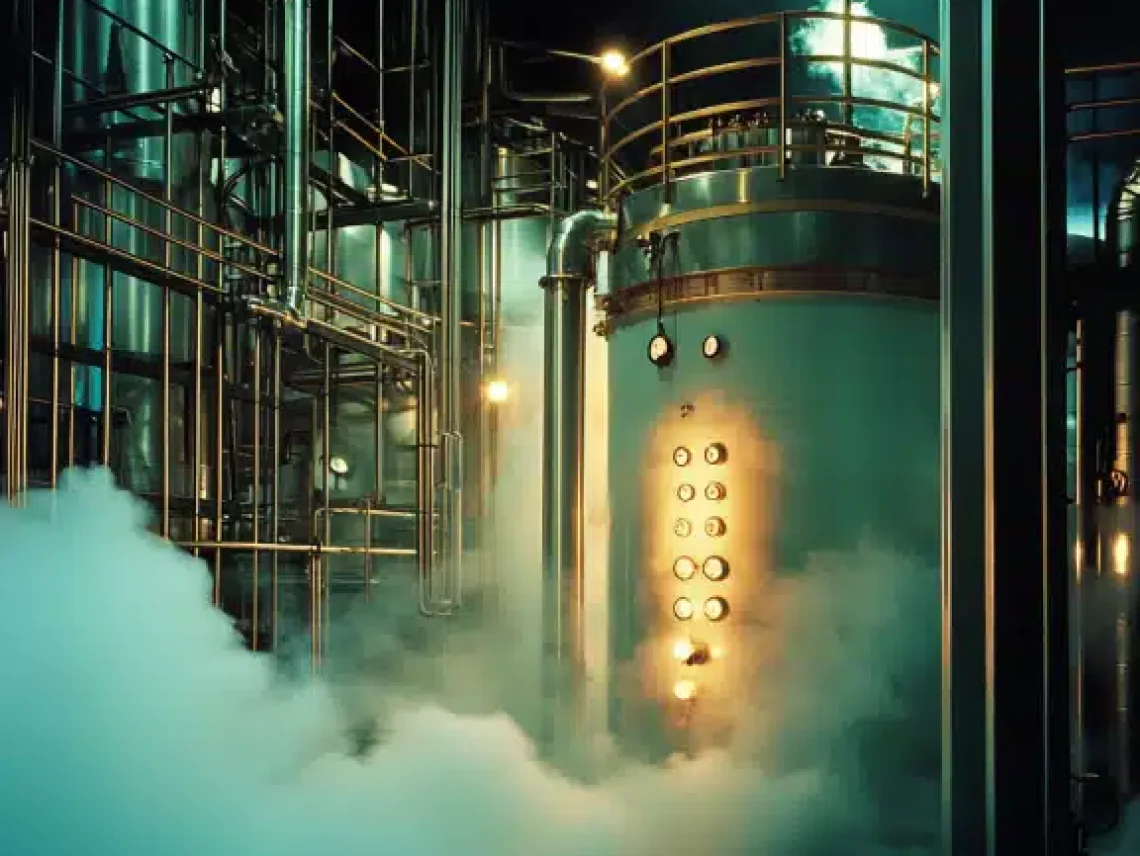

Venting refers back to the intentional launch of vapor from cryogenic tanks. It happens due to elements including temperature fluctuations, pressure buildup, and the need to preserve the most excellent conditions in the tank. Venting ensures safety by stopping overpressure situations that would lead to system failure.

Importance of Addressing Venting in Cryogenic Storage

Addressing venting in cryogenic storage is crucial for retaining operational performance and protection. Proper venting procedures help alter pressure, save you from tank damage, and ensure the integrity of stored substances. Understanding the dynamics of venting is essential for effective cryogenic tank control.

Factors Influencing Cryogenic Tank Venting

Temperature Fluctuations and Their Impact

Temperature fluctuations can cause variations in vapor pressure in internal cryogenic tanks, leading to the want for venting to maintain the finest conditions. Understanding how temperature adjustments affect vaporization rates is critical for handling venting efficiently.

Pressure Buildup in Cryogenic Tanks

Pressure buildup in cryogenic tanks can arise due to elements like ambient temperature adjustments, filling and emptying operations, and heat switches from external assets. Proper pressure comfort mechanisms, along with relief valves, are vital to save you from overpressurization and ensure safe operation.

Type and Quality of Insulation Materials

The kind and exceptional insulation materials utilized in cryogenic tanks play an important position in minimizing warmness transfer and preserving stable inner temperatures. High-satisfactory insulation helps reduce the frequency and extent of temperature fluctuations, thereby minimizing the want for excessive venting.

Technical Considerations in Cryogenic Tank Venting

Pressure Relief Valve Functionality

Pressure alleviation valves are critical components in cryogenic tank venting systems. These valves robotically launch excess pressure to save your storage harm and make sure of secure operation. Understanding the functionality and preservation requirements of pressure remedy valves is crucial for powerful venting management.

Venting Mechanisms and Systems

Various venting mechanisms and structures are utilized in cryogenic tanks, such as guide and automatic venting structures. Choosing the correct venting device relies upon factors including tank size, software requirements, and protection concerns. Regular inspection and renovation of venting systems are essential to ensure their reliability and effectiveness.

Safety Protocols and Regulations

Safety protocols and regulations govern the layout, operation, and preservation of cryogenic tank venting structures. Compliance with these standards is vital for ensuring place of work protection and stopping environmental dangers. Implementing complete safety protocols and accomplishing ordinary schooling classes for personnel help mitigate risks associated with cryogenic tank venting.

Need a reliable partner?

FAQ’s

How do temperature fluctuations affect cryogenic tank venting?

Temperature fluctuations can significantly impact cryogenic tank venting. When the ambient temperature rises, the temperature inside the tank can also boom, causing the saved liquid to vaporize and create excess pressure. This pressure buildup can also necessitate venting to preserve secure working conditions in the tank.

What protection measures are in place to save you overpressurization of cryogenic tanks?

Cryogenic tanks are prepared with protection mechanisms along with pressure comfort valves, which routinely launch extra pressure to save you from overpressurization. These valves are designed to open at a predetermined pressure threshold, permitting the release of vapor until the pressure returns to safe stages.

How can operators minimize the environmental effect of cryogenic tank venting?

Operators can minimize the environmental impact of cryogenic tank venting by way of enforcing green venting strategies and adhering to environmental policies. This may also consist of shooting and recycling vented gases, using environmentally friendly insulation materials, and tracking emissions to ensure compliance with regulatory standards.

What are the regulatory necessities for coping with cryogenic tank venting?

Regulatory requirements for managing cryogenic tank venting range depending on the vicinity and industry requirements. However, not unusual guidelines may additionally consist of hints for pressure comfort valve sizing, venting frequency, emissions monitoring, and reporting necessities. Operators ought to make certain compliance with those guidelines to hold safe and environmentally responsible operations.

Can cryogenic tank venting be eliminated?

While it can no longer be feasible to eliminate cryogenic tank venting, operators can put in force diverse measures to minimize venting losses. This can also consist of optimizing insulation, improving pressure manipulation systems, reducing temperature fluctuations, and imposing green venting strategies. By using these measures, operators can mitigate venting losses and optimize the efficiency of cryogenic tank operations.

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.