Table of Contents

ToggleThe term “skid” might evoke various images in one’s mind, ranging from a wooden pallet used in warehouses to a car losing control on an icy road. But what exactly is a skid, and why is it a term that finds relevance in so many different contexts? A skid, in its most basic definition, refers to a platform or an action of sliding. However, its application and meaning can vary widely depending on the industry and the specific context in which it is used.

Understanding the concept of a skid is crucial not just for professionals in logistics, automotive, or aviation sectors but also for the general public. Whether it’s ensuring safe driving in adverse weather conditions or optimizing warehouse storage, skids play an essential role in various industries. Consequently, their implications touch multiple aspects of our daily lives.

The word “skid” also finds its origins in maritime language. Historically, ships were often built or repaired on a set of beams, which were also referred to as skids. Once the construction was complete, and the ship was ready to be launched, it would gradually “skid” into the water, giving rise to the phrase “being on the skids.” This expression later took on a broader meaning, referring to something in decline or in preparation for a transition.

This phrase gained a new meaning in the automotive world in the 20th century. As cars became more prevalent, so did the challenges of handling them in various conditions. The action of a car losing traction and sliding, especially on wet or icy roads, came to be known as “skidding.”

When a vehicle begins to skid, knowing proper recovery techniques can mean the difference between regaining control and experiencing a serious accident. The key to safe skid recovery is remaining calm and applying the correct steering and braking techniques based on the type of skid encountered.

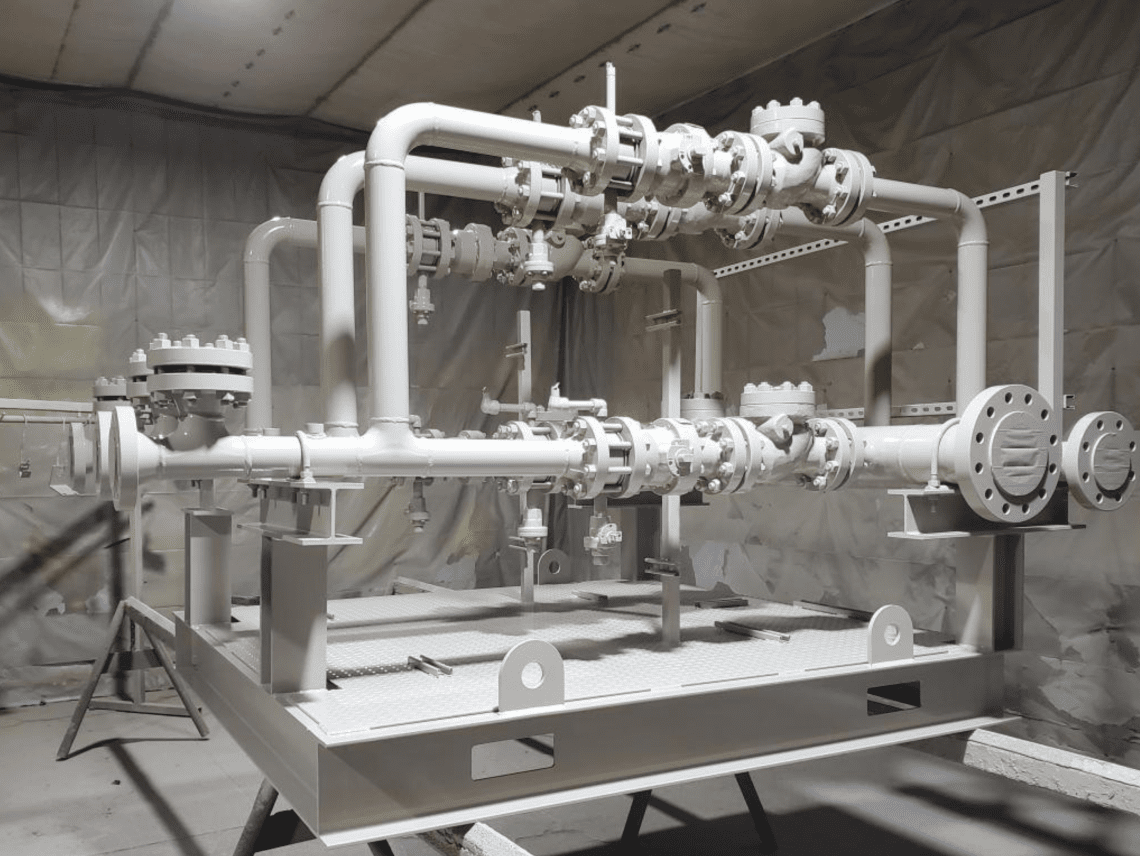

A skid in pressure vessel systems refers to a frame or platform that supports the pressure vessel and its associated components, such as piping, valves, and instrumentation. It’s designed for easy transportation and installation, allowing the entire system to be assembled, tested, and shipped as a unit. This modular approach simplifies the integration of the pressure vessel into various industrial processes.

Engineered for efficiency, skid-mounted pressure vessels provide a compact and pre-assembled alternative to traditional setups. Designed for plug-and-play operation, they significantly reduce on-site installation time and complexity. Unlike conventional systems, which require on-site assembly and connection, these units save space and streamline the setup process.

The primary benefits include:

Designed for flexibility, skid-mounted pressure vessels offer space efficiency and time savings, making them essential in industries such as oil and gas, chemical processing, pharmaceuticals, and power generation. Their modular design enables quick adaptation to evolving process requirements, making them ideal for industries with rapidly advancing technologies and operational demands.

Absolutely. Skid-mounted pressure vessels can be tailored to meet specific operational requirements. Customization can include the size and material of the pressure vessel, the configuration of piping and valves, control systems, and instrumentation. This flexibility ensures that the skid-mounted system integrates seamlessly with existing processes and meets the unique demands of different industries.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.