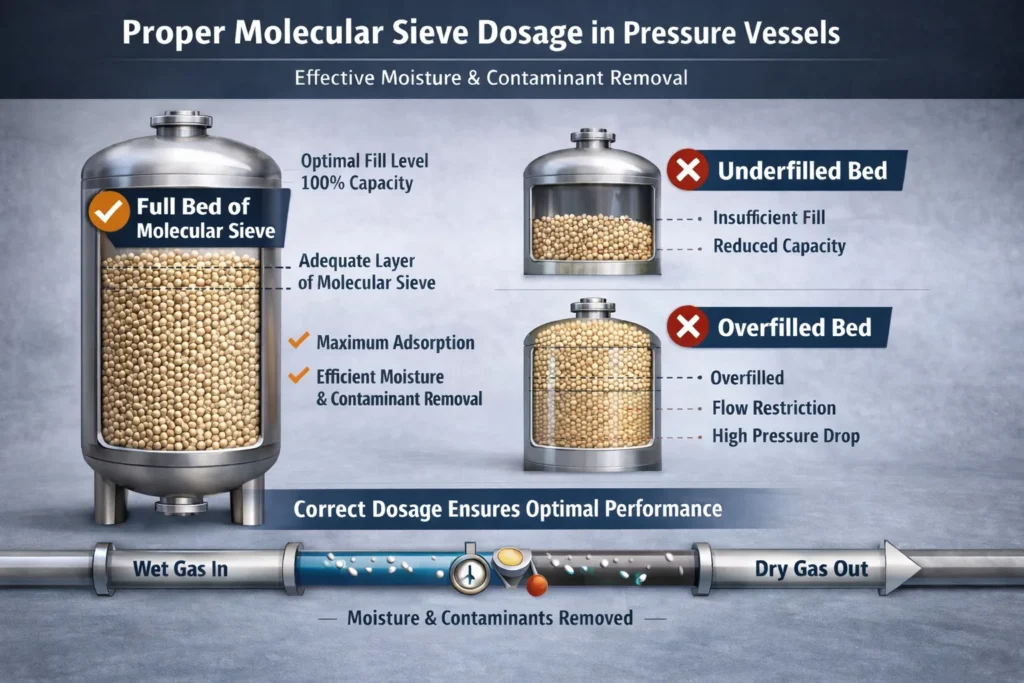

Using the correct molecular sieve dosage is critical to achieving effective moisture and contaminant removal without unnecessary material waste. Optimal sizing based on process conditions such as flow rate, pressure, temperature, and contaminant load improves efficiency, reduces downtime, and enhances overall system reliability.

Optimal Molecular Sieve Usage

Optimizing molecular sieve usage is essential for maximizing the efficiency of industrial processes, from natural gas treatment to chemical purification. At Red River, with over 25 years of experience in pressure vessel design and process optimization, we understand the precise calculations and variables that drive performance.

What Are Molecular Sieves and Why Are They Important?

Molecular sieves are highly porous substances used to separate and purify gases and liquids based on molecular size and polarity. Their ability to absorb moisture and trap unwanted contaminants makes them indispensable in various industrial applications. According to a U.S. Department of Energy study, molecular sieves are particularly effective in drying sour natural gas to extremely low dew points. Choosing the correct amount of molecular sieves is critical for achieving optimal molecular sieve usage. Too little can hinder performance, while too much may waste valuable resources. Learn more about activating molecular sieves and properly washing them.

Applications of Molecular Sieves in Industrial Processes

Molecular sieves are versatile tools utilized across numerous industries. In the oil and gas sector, they are essential for drying and purifying natural gases, preventing impurities from damaging equipment. A case study from EPA HERO highlights the importance of molecular sieves in offshore gas processing environments where high CO₂ concentrations challenge conventional drying methods. In the energy industry, they maintain gas quality, resulting in more efficient combustion and energy production. Regardless of the application, determining the right molecular sieve quantity can significantly enhance your equipment’s performance. For more insights, explore Where Are Molecular Sieves Used? Understanding Their Applications and Benefits

Factors Affecting Molecular Sieve Efficiency

Several factors impact the performance of molecular sieves, including temperature, pressure, and the characteristics of the substances being processed. Understanding these variables is crucial for ensuring optimal molecular sieve usage. For instance, higher temperatures may require adjustments to the molecular sieve dosage, as fluctuating pressures can influence their capacity to perform efficiently. Related guidance can be found in Understanding Desiccant Dryers and Adsorption Air Dryers.

Calculating the Optimal Amount of Molecular Sieves

Determining the precise quantity of molecular sieves is key to achieving reliable separation and minimal process downtime. For example, in a dehydration system treating 10 MMSCFD of natural gas, a typical 4A sieve bed might require ~2000–2500 lbs depending on water content and cycle time. The ideal dosage varies based on gas composition, pressure, and allowable dew point. At Red River, we recognize the importance of precision in this method, which is why we’ve evolved a trustworthy approach that will help you get it proper. Check out our guide on drying molecular sieves for more details.

Step-by-Step Guide to Determining Molecular Sieve Quantity

Start by identifying the unique requirements of your process, including factors like gas composition, temperature, and pressure conditions. Next, determine the type and size of molecules you need to separate. These details will guide your choice of sieve type. Finally, calculate the required amount using industry-standard formulas or consult our experts for personalized recommendations.

Common Mistakes in Measuring Molecular Sieves

Underestimating the amount needed can lead to inefficient separation and higher operational costs. Overestimating can result in wasted resources and unnecessary expenses. Avoid these pitfalls by ensuring accurate measurements and considering all operational variables. Learn more about molecular sieve lifespan and maintenance.

Tools and Formulas for Accurate Molecular Sieve Calculation

Use sieve calculators and specialized software to ensure precision. These tools account for molecular size, pressure, and temperature. Standard molecular sieve design methodology, published on OSTI.gov provides regeneration scheduling models and economic performance baselines.

Variable | Typical Range | Affects |

Molecular Size (Å) | 3A, 4A, 5A, 13X | Type of sieve required |

Operating Pressure | 50–1200 psi | Adsorption capacity |

Operating Temp | -20°C to 250°C | Regeneration frequency |

Flow Rate | 0.5–50 MMSCFD (gas) | Sizing of sieve beds |

Best Practices for Using Molecular Sieves in Your Operations

Using molecular sieves efficiently requires attention to detail and adherence to tested practices. At Red River, we’ve compiled a set of best practices to help you maximize performance and achieve reliable results.

Tips for Ensuring Maximum Efficiency

Track and maintain your system regularly. Check for signs of saturation or decreased performance and replace sieves as needed. Ensure flow rates and pressure levels remain within the recommended range for your sieve type. Consistent operational parameters are key. For additional guidance, see Understanding Desiccant Dryers and Understanding Adsorption Air Dryers.

How to Adjust Molecular Sieve Usage Based on Process Needs

Your process needs may change over time, requiring adjustments to your molecular sieve usage. If you’re also concerned about reuse and efficiency over the long term, review Understanding Molecular Sieve Lifespan

Case Studies: Successful Molecular Sieve Implementations

At Red River, we’ve helped numerous customers optimize their operations through powerful molecular sieve implementations. One such case involved a client in the oil and fuel enterprise who faced frequent device downtime due to moisture contamination. By recalculating and adjusting their molecular sieve utilization, we reduced downtime by 30%, extensively improving their average operational efficiency. Let us help you achieve similar fulfillment for your operations.

Maximizing Efficiency with Optimal Molecular Sieve Usage

Achieving the right molecular sieve dosage is crucial for efficient moisture and contaminant removal, cost savings, and reliable system performance. By carefully matching sieve type and quantity to process conditions, monitoring operational parameters, and applying best practices, industrial operations can optimize performance, reduce downtime, and extend equipment lifespan.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions

1. What factors should I not forget whilst selecting the form of molecular sieve for my application?

When selecting a molecular sieve, bear in mind elements such as the molecular length and polarity of the materials you want to separate, in addition to the working temperature and pressure conditions. Additionally, think about the particular contaminants you want to remove and the float price of the gasoline or liquid passing through the sieve. The choice of molecular sieve also can rely upon whether your application includes adsorption of water, gases, or unique chemical substances. It’s essential to fit the sieve type with your particular method requirements to ensure premier performance.

2. How often should molecular sieves be replaced or regenerated?

The frequency of substitute or regeneration of molecular sieves relies upon the unique software and the level of contaminants being filtered. In trendy, sieves need to be regenerated once they attain their saturation factor, that is when they can not successfully adsorb molecules. This may be decided by tracking the overall performance of the machine, together with checking for extended moisture stages or a drop in performance. In many instances, molecular sieves can be regenerated by making use of heat to dispose of the absorbed molecules, a technique known as thermal regeneration. The specific regeneration agenda has to be primarily based on the operational parameters and the type of sieve used.

3. Can I use exceptional varieties of molecular sieves in equal application?

Yes, the use of one-of-a-kind types of molecular sieves in a layered or sequential arrangement is not an unusual exercise in complicated packages. This technique allows for the elimination of various contaminants or the optimization of the adsorption method. For example, you might use one sort of sieve to put off water and any other to filter particular gases or chemicals. The secret is to lay out the system so that every sieve is running within its premier variety and correctly addressing the specific needs of your method.

4. What are the capability consequences of using an excessive amount of or too little molecular sieve cloth?

Using too much molecular sieve material can cause useless costs and capacity pressure drops in the machine, which may additionally affect the overall performance of the operation. On the other hand, the use of too little material can result in incomplete adsorption, allowing contaminants to pass through the machine and doubtlessly harm the device or affect the product. It’s critical to calculate the optimum amount of molecular sieve needed based on your unique system conditions to keep away from those troubles. Over time, best-tuning the amount used can lead to higher overall performance and fee savings.

5. How do temperature and pressure impact the performance of molecular sieves?

Temperature and pressure are critical elements in the overall performance of molecular sieves. Generally, better temperatures can lessen the adsorption capability of molecular sieves, because the absorbed molecules can be released or not adsorbed as successfully. Conversely, lower temperatures regularly decorate the adsorption capability however may also slow down the overall method. Pressure additionally performs a giant function; better pressures can grow the adsorption price, making the procedure greater efficient. However, it’s vital to maintain the pressure inside the operational limits of the device and the particular molecular sieve being used. Balancing temperature and pressure is fundamental to maximizing the performance of molecular sieves in any software.

Key Takeaways

- Precision matters: Correct molecular sieve dosage is essential to maintain process efficiency and avoid equipment issues.

- One size doesn’t fit all: Dosage and sieve type must match process variables like pressure, temperature, and contaminant profile.

- Monitoring is non-negotiable: Regularly check for saturation, adjust usage based on production changes, and regenerate as needed.

- Avoid common pitfalls: Overfilling wastes money; underfilling leads to incomplete adsorption and potential system failure.

- Expert tools help: Use calculators and consult experienced engineers to get dosage right the first time.

- Proven results: Red River’s optimizations have helped clients reduce downtime by up to 30%.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

- Understanding Molecular Sieves and Their Role in Water Removal

- Where Are Molecular Sieves Used? Understanding Their Applications and Benefits

- Understanding Molecular Sieves and Their Role in Solvent Drying

- Understanding Molecular Sieves in Breathing Air Systems

- How to Make a Molecular Sieve Device A Step-by-Step Guide