In modern logistics, a plastic skid serves as a durable platform for transporting, storing, and protecting goods. Unlike wooden skids, plastic skids resist moisture, contamination, and wear, offering superior hygiene and long-term savings. This article explores the definition, benefits, and practical uses of plastic skids so you know why they matter for your operations.

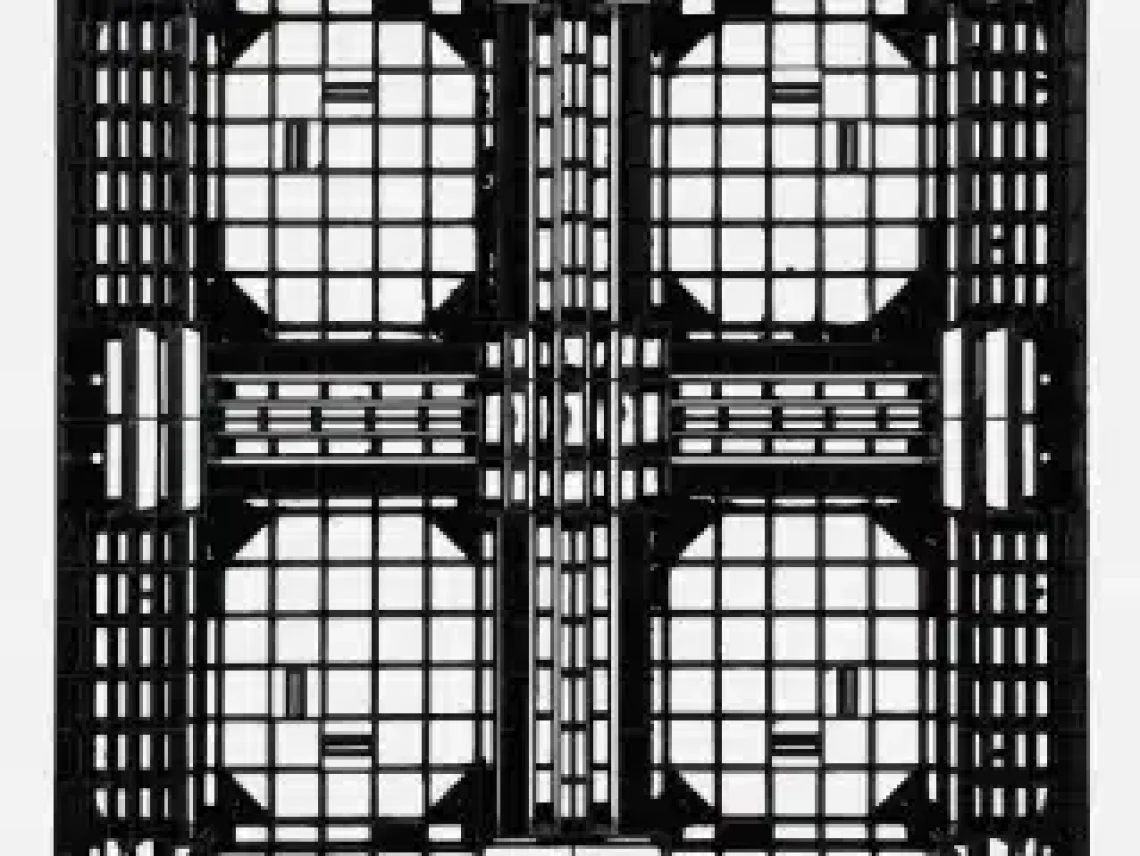

A plastic skid—also known as a plastic pallet or platform—is a flat, elevated structure made from polyethylene (PE) or polypropylene (PP). It’s designed to support loads during transport, warehousing, and stacking. Unlike traditional wood designs, plastic skids provide uniform strength and dimensions, making them highly compatible with warehouse operations.

Durability: Plastic skids resist rot, splintering, and chemical damage, making them more reliable than a basic skid.

Hygiene: Non-porous surfaces make them easy to clean, which is vital in industries like food and pharmaceuticals.

Weight Efficiency: They are lighter than wooden or metal options, helping reduce transport costs.

Consistency: Precise dimensions allow smooth use with forklifts and automated systems.

Customization: Options include anti-slip surfaces, reinforced corners, and branding.

Compared to wooden skids, plastic skids offer longer service life and improved hygiene. Wooden skids may appear cost-effective initially but often require more repairs. To learn more about differences, see our guide on Skids vs Pallets.

External studies support this: research in ScienceDirect has compared microbial loads on wooden and plastic pallets, showing that sanitation practices strongly influence performance.

Plastic skids manufactured from recycled materials reduce waste and support sustainability. They are fully recyclable at the end of their life cycle. According to a ScienceDirect lifecycle assessment, plastic pallets may have higher production impacts but often outperform wooden ones when reused many times.

Plastic skids are essential in:

Food and beverage processing

Pharmaceuticals and healthcare

Cold storage and temperature-sensitive logistics

Manufacturing and heavy equipment

For real-world examples, see our article on Exploring Skid Applications.

While plastic skids have a higher upfront cost, they require less maintenance and fewer replacements. Businesses moving large quantities of goods can also calculate loading capacity, such as in our guide on Determining the Number of Boxes That Fit on a Skid.

Plastic skids combine hygiene, durability, and operational efficiency. They outperform wooden alternatives in many scenarios and provide long-term cost savings. For industries that demand compliance, safety, and sustainability, plastic skids are the future of logistics.

Red River specializes in custom skid solutions that meet modern logistics demands. Whether you need consistency, hygiene, or durability, our team can help. Contact us today and see why companies trust us for high-quality skid fabrication.

A plastic skid is a load-bearing platform often used interchangeably with pallets, but it usually has a simpler base design and fewer components.

Yes. Plastic skids are easier to clean because of their smooth surfaces. Studies on pallet hygiene confirm that sanitation practices matter more than material type.

Most are manufactured from high-density polyethylene (HDPE) or polypropylene (PP), both known for durability and resistance to chemicals.

Plastic skids can last significantly longer, especially in humid or chemical-heavy environments, while wood is prone to warping and splintering.

When made from recycled materials, yes. Research on supply chain life cycles shows reuse and recycling are key to reducing environmental impact.

Absolutely. Many can be tailored with anti-slip surfaces, reinforced corners, or designed dimensions to meet unique operational needs.

Plastic skids are stronger, cleaner, and longer-lasting than wood.

They save costs over time due to fewer replacements.

Sustainability depends on recycling and lifecycle usage.

Customization makes them adaptable across industries.

Studies confirm their value in modern supply chains.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.