Table of Contents

ToggleUnderstanding the average dimensions of a wooden pallet is fundamental to effective logistics, storage, and transportation. In the world of shipping and warehousing, pallet sizes directly affect space optimization, cost-efficiency, and the safety of goods in transit. This guide will take you through the standard pallet sizes, their uses, and how to choose the right size for your needs.

Wooden pallets are essential to the global supply chain. Used for storing, stacking, and transporting goods, they are typically made from wood, and their dimensions vary depending on region, industry, and specific needs. The average dimensions of a wooden pallet in North America are generally 48 inches by 40 inches (1219 mm x 1016 mm), but various other sizes are common in different regions, like the Euro Pallet or the Asia Standard pallet.

For a deep dive into pallet design and function, check out Skids vs. Pallets, where we break down the differences between these vital shipping tools.

The 48 x 40-inch GMA pallet is the most common size in North America, predominantly used in industries like food, retail, and logistics. This size offers maximum compatibility with storage racks and is considered the standard in the U.S.

The Euro Pallet, often used in Europe, measures 47.2 x 31.5 inches (1200 x 800 mm). This pallet is widely accepted for international trade and is regulated by the European Pallet Association (EPAL), ensuring quality standards and uniformity across regions.

The 40 x 40-inch square pallet is often used for specific industries such as retail and food service, where compact sizes are necessary. It is perfect for smaller or oddly shaped loads.

Commonly used in the Asia-Pacific region, the 47.2 x 39.4-inch pallet offers more surface area than the Euro pallet, which makes it ideal for larger shipments and bulkier goods.

To learn more about the differences between pallets and skids, visit The Difference Between a Skid and a Crate.

Choosing the correct pallet size is crucial for operational efficiency. Here’s why:

Space Optimization

Choosing the right pallet size helps optimize space in warehouses and shipping containers. Using the correct dimensions ensures that pallets fit seamlessly into storage racks and maximize available space. More about space optimization can be found in this logistics article.

Cost Control

By selecting the appropriate pallet size, you minimize the number of pallets needed for shipping and reduce shipping costs. Pallets that perfectly fit containers maximize space, cutting down on unnecessary freight expenses.

Compatibility with Handling Equipment

The right pallet size ensures compatibility with forklifts and pallet jacks, facilitating smooth and safe handling of goods during storage and transportation. Ensuring the correct pallet size for handling equipment is critical for minimizing damage and delays.

Regional Standards and Regulations

In many industries, using the wrong pallet size can result in delays or fines. For example, Euro Pallets (1200 x 800 mm) are the standard in Europe, while the GMA pallet (48 x 40 inches) is most common in North America. Learn more about regional standards in our article on Understanding Pallet Regulations

To conclude, the average dimensions of a wooden pallet significantly influence logistics, space management, and shipping costs. Whether you’re looking to optimize warehouse storage or improve shipping efficiency, understanding the most common pallet sizes—such as the 48 x 40-inch GMA pallet is key. Selecting the right pallet for your specific needs ensures smoother operations and cost savings.

Ready to optimize your pallet selection and logistics process? Visit Red River Team to explore customized pallet solutions designed for your business needs.

The 48 x 40-inch GMA pallet is the most common size in North America. It is the industry standard because it fits most racking systems, forklifts, and shipping containers, making it highly versatile for retail, food, and manufacturing industries.

Yes. Pallets can be built to match unique product dimensions, weight requirements, or regional shipping standards. Businesses often use custom pallets for oversized equipment, bulk materials, or when optimizing for transport efficiency and reduced product damage.

Wooden pallets are usually made from:

Hardwood (oak, maple) for strength and heavy-duty loads.

Softwood (pine, spruce) for lighter, cost-effective solutions.

Some also use recycled or composite wood to reduce costs and support sustainability.

A standard pallet holds up to 4,600 pounds (2,100 kg) with evenly distributed loads. Actual capacity depends on pallet design (block or stringer), type of wood, and load distribution. Heavy-duty models can handle more.

It depends on your needs:

Plastic pallets are lightweight, durable, and resistant to moisture, making them ideal for hygiene-sensitive industries (pharma, food).

Wooden pallets are cheaper, easy to repair, and widely accepted worldwide.

Consider:

Product dimensions & weight (to avoid overhang and damage).

Warehouse storage (must fit racks and forklifts).

Transport needs (must comply with carrier or container standards).

Budget vs. durability (wood vs. plastic).

Yes, but they must meet ISPM-15 standards. This means pallets must be heat-treated or fumigated and stamped to prevent the spread of pests. Non-compliance can result in customs delays, fines, or shipment rejection.

The 48 x 40-inch GMA pallet is the most widely used standard size.

Euro Pallets are regulated by the European Pallet Association (EPAL) for international use.

Choosing the right pallet size is crucial for space optimization and reducing shipping costs.

Wooden pallets come in various materials such as hardwood and softwood for different needs.

Always ensure pallets meet international shipping standards when shipping overseas.

For more information on pallet sizes and their use in logistics, visit our article on Understanding the Purpose of Skids.

Table of Contents

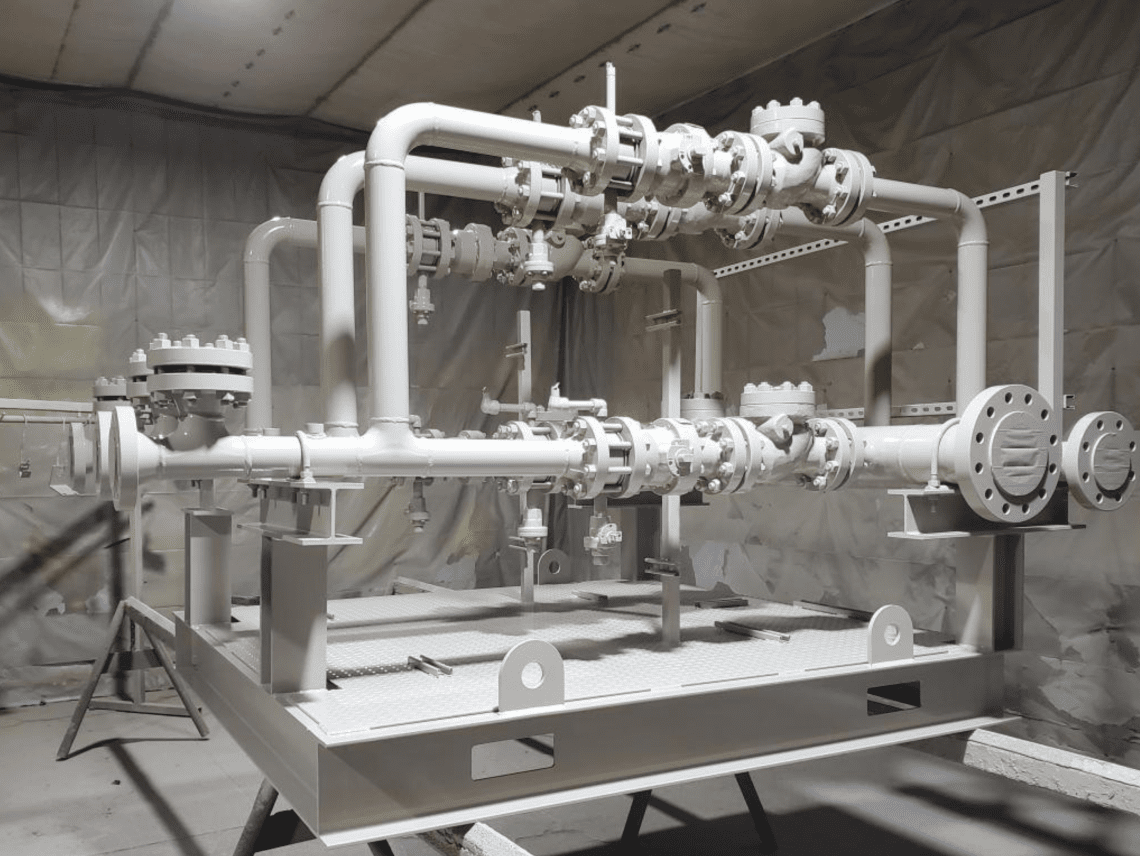

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.