Table of Contents

ToggleWhen you hear the phrase braking and skidding in physics, it might bring back memories of high school science—or stressful moments behind the wheel! But this topic is far more than classroom theory. Understanding the physics of braking and skidding isn’t just for engineers—it’s essential for drivers, fleet managers, and anyone dealing with mechanical systems.

Skidding occurs when friction between tires and the road is lost, resulting in dangerous sliding. The science behind this—friction coefficient, Newton’s Laws, and the relationship between speed, force, and stopping distance—can save lives. We’ll explain not just what happens, but why it happens, with practical tips, equations, and expert sources.

If you’re interested in deeper engineering and modular design, check out our post on gas modular skids or learn more about mechanical skids in process systems.

Skidding is when a vehicle’s tires lose grip and begin sliding uncontrollably, often due to sudden braking or turning on slippery surfaces. In physics, this occurs when the frictional force is overcome by the forces acting on the vehicle, like inertia and gravity. The science of skidding can be explored further through Wikipedia’s article on skidding.

Physics teaches us that friction is what allows us to stop a moving vehicle. The two types that matter most are static friction (prevents sliding) and kinetic friction (occurs during sliding). Braking relies on static friction until the tires start to skid, at which point kinetic friction—which is weaker—takes over, reducing control.

Newton’s Second Law is fundamental here: Force = Mass x Acceleration.

Braking Distance Formula:

Braking Distance=v22μg\text{Braking Distance} = \frac{v^2}{2\mu g}Braking Distance=2μgv2where v is velocity, μ is the friction coefficient, and g is gravity (source).

On wet or icy roads, μ drops dramatically, making skids far more likely. Anti-lock Braking Systems (ABS) help maintain static friction, and understanding these dynamics is key for both drivers and engineers. For an applied example, see our guide on different types of skids and how they affect modular process systems in our dosing skid explainer.

Friction is the hero and villain of vehicle safety. Static friction keeps you steady, while kinetic friction takes over if you skid—and is always lower.

On dry asphalt, μ can be as high as 0.9.

On ice, it can drop below 0.2—making braking and skidding in physics a real-world concern (Wikipedia – Coefficient of Friction).

Several factors impact whether or not you’ll skid:

Speed: Higher speeds increase stopping distance exponentially.

Road Conditions: Water, ice, oil, and even loose gravel reduce friction.

Tire Health: Worn tires have less grip—check your treads often.

Vehicle Load: Heavier vehicles may need more distance to stop.

Braking Technique: Sudden, hard braking can induce skidding, especially without ABS.

For pipeline and industrial systems, similar principles apply! Learn how skids work in pipeline operations or see why skids differ from pallets in process industries (explained here).

Slow Down: Especially on wet or icy roads.

Check Your Tires: Good tread and correct pressure are vital.

Brake Gently: Apply even pressure; don’t slam the brakes.

Stay Focused: Anticipate hazards—avoid sharp turns at speed.

Maintain Your Vehicle: Ensure brakes, ABS, and suspension are in good order.

Train for Emergencies: Consider advanced driver training or research road safety tips from government sources.

If you work with modular process or CIP skids, check out our article on CIP skids to see how design can prevent process “skids” too!

Braking and skidding in physics isn’t just theory—it’s daily reality. Whether you’re behind the wheel or engineering a process skid, understanding friction, force, and motion can help you stay safe, reduce accidents, and make smarter decisions.

Stay curious, stay cautious, and always respect the laws of physics—they’re non-negotiable!

Want to become a true expert in modular design, vehicle safety, or engineering systems?

Explore our deep-dive guides and join our community for the latest tips:

For tailored solutions or consulting, contact our team today!

Skidding in physics happens when the frictional force between the tires and the road is no longer strong enough to counter the vehicle’s momentum, leading to loss of control.

Friction determines how quickly and safely you can stop. High friction (dry roads) means better stopping power; low friction (wet or icy roads) means longer stopping distances and more skidding risk.

Braking distance = (speed²) ÷ (2 × friction coefficient × gravity). For more, see Wikipedia on Braking Distance.

ABS prevents wheel lock-up by rapidly pulsing brake pressure, keeping tires within the static friction zone for optimal grip and control.

No, but you can greatly reduce the risk by driving cautiously, maintaining your tires, and using correct braking techniques—especially in bad weather.

Wet, icy, or loose surfaces reduce friction, making it much easier for tires to lose grip and for a skid to occur.

Heavier vehicles require more distance to stop and are harder to control in a skid. Always adjust your driving for your load.

A modular skid is a pre-assembled process unit, while a pallet is simply a platform for moving materials. Learn more in our comparison article.

Braking and skidding in physics is about friction, force, and safety—critical for drivers and engineers alike.

Friction type (static vs kinetic) determines if you grip or skid.

Poor road conditions, worn tires, and high speed all raise the risk of skidding.

Proper maintenance and smart driving are your best defense.

Physics formulas help explain and predict real-world safety outcomes.

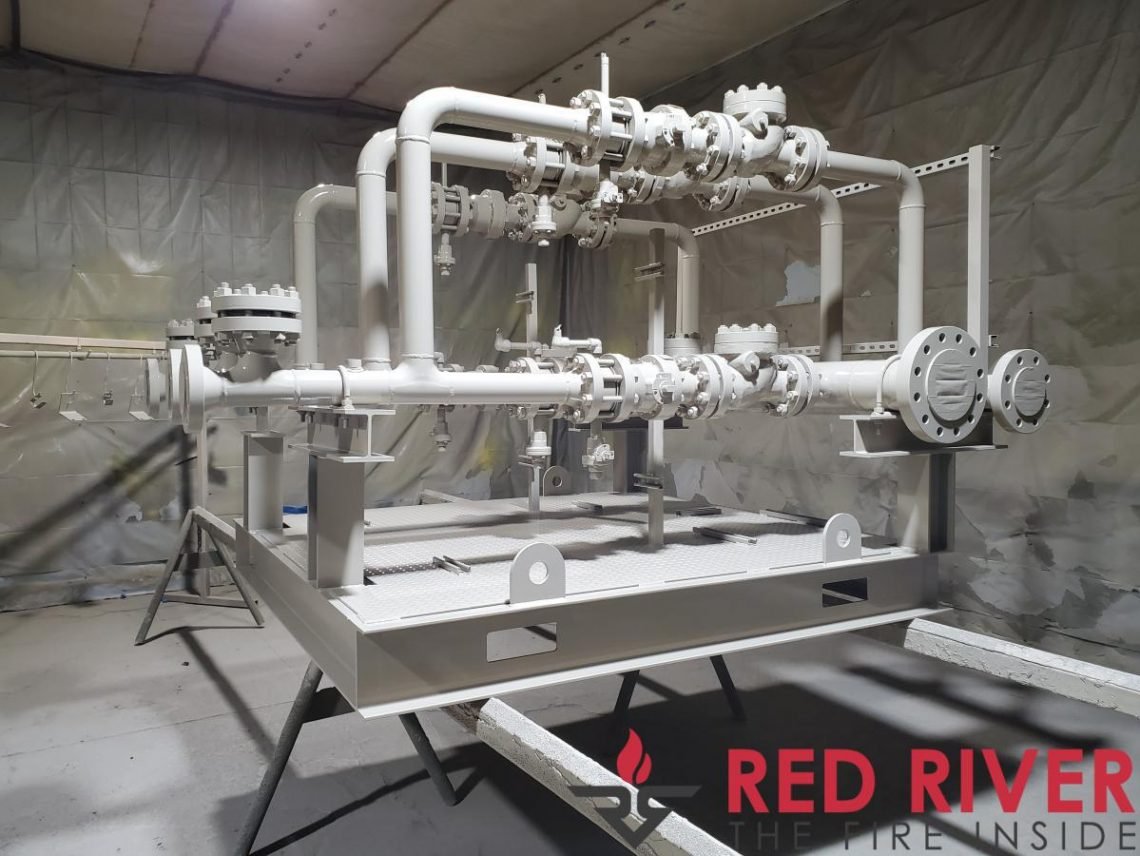

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.