Table of Contents

Toggle

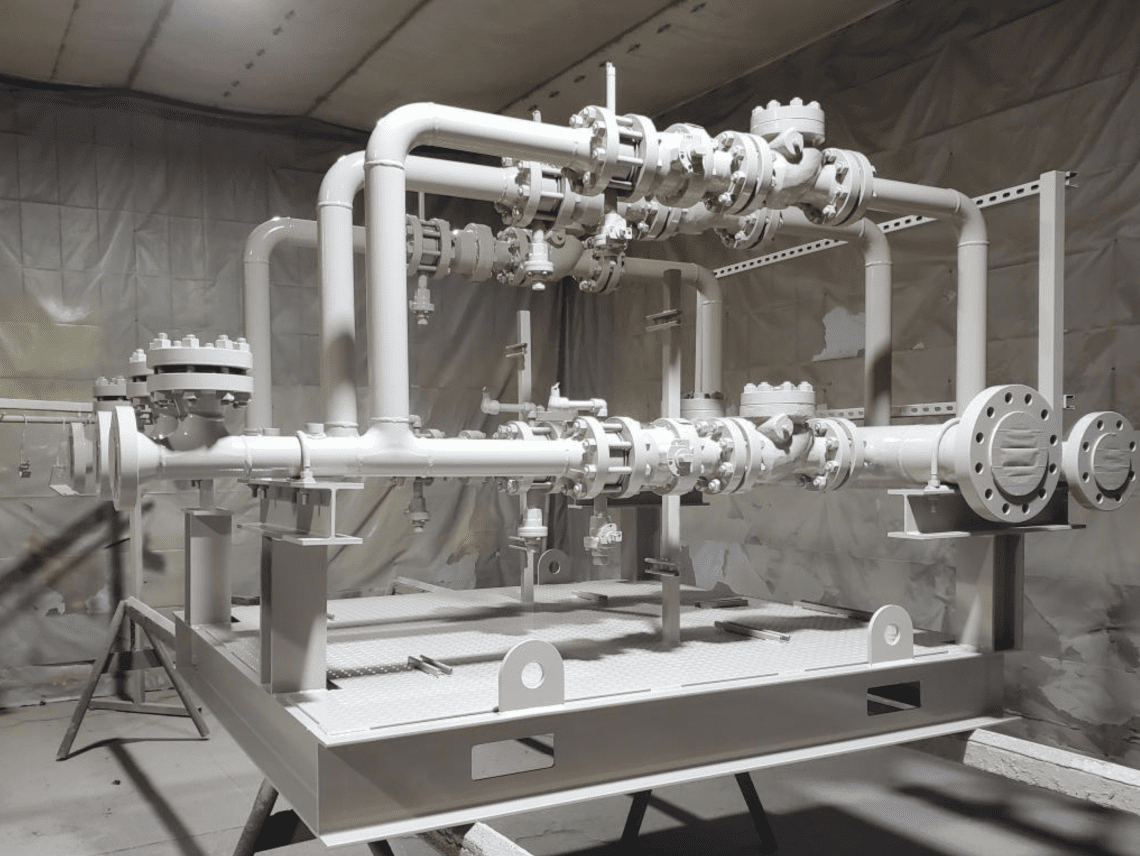

At its core, a skid mounted system is a modular assembly of equipment mounted onto a steel frame or platform that can be easily transported and installed at different sites. Unlike traditional fixed equipment installations, skid mounted systems are built off-site, fully assembled, and tested before being delivered to the operational location.

A typical skid mounted system consists of:

This all-in-one modular design enables the system to be transported as a single unit and installed with minimal on-site assembly.

Traditional industrial setups often require building and assembling equipment directly on-site, which involves significant labor, time, and sometimes operational disruptions. Skid mounted systems, by contrast, minimize on-site work by delivering a turnkey, tested package that just needs to be connected to utilities like power, water, or fuel.

Skid mounted systems are highly versatile and find application in numerous industries:

Each industry benefits from the skid system’s portability, modularity, and reduced installation complexity.

Skid mounted systems offer several distinct benefits that make them attractive to project managers, engineers, and operators.

Because skid mounted systems are built on compact, steel frames, they can be moved by forklifts, cranes, or flatbed trucks. This portability allows companies to relocate equipment between sites or scale operations quickly without rebuilding entire setups.

Since the system is pre-assembled and tested off-site, installation at the final location is much faster. This reduces labor costs and minimizes downtime for operations. Projects with tight timelines particularly benefit from skid-mounted units.

The modular design facilitates easier inspection, repair, or replacement of components. Maintenance teams can work on the skid in a controlled environment before redeploying it, improving safety and efficiency.

Skid mounted systems can be tailor-made to meet specific process requirements and space constraints. They can also be designed for future expansion, making it easy to add modules or upgrade equipment as needed.

Due to their flexibility, skid mounted systems are used in various industrial applications

Many fluid processing operations rely on skid mounted systems to handle pumping, filtering, or treating liquids and gases. For example, chemical plants use skid units for dosing chemicals, while oil refineries may have skids for separating hydrocarbons.

Skid mounted pump packages or compressor units are common in industries like oil and gas, mining, and water treatment. These units deliver the necessary pressure and flow control while being easy to relocate or replace.

Water treatment and wastewater management facilities often use skid mounted filtration systems that can be quickly installed and integrated into existing pipelines. Separators and coalescers mounted on skids help remove contaminants from process streams.

Skid mounted HVAC units are used in industrial settings to provide controlled heating and cooling. Their modular nature makes them ideal for temporary setups or facilities with limited space.

Selecting the right skid mounted system requires careful evaluation of several factors:

Assess the available space at your site and the logistics of transporting the skid. The skid size must fit the access routes and installation footprint.

Define process needs, including flow rates, pressure levels, and environmental conditions. The system must meet these parameters reliably.

Ensure the skid design complies with relevant industry standards, such as ASME codes for pressure vessels or API standards for oil and gas equipment. Compliance guarantees safety and regulatory approval.

Consider whether the system may need to be upgraded or expanded. Modular skid designs allow for easier integration of additional equipment down the line.

Skid mounted systems provide a flexible, efficient, and cost-effective approach to industrial equipment installation and operation. Their portability and modular design significantly reduce project timelines and operational disruptions. Whether you are building a new plant or upgrading an existing facility, considering a skid mounted system can deliver tangible benefits in installation ease, maintenance, and scalability.

For companies focused on streamlining complex processes, skid mounted systems represent a smart solution that balances performance with practical logistics.

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

A skid mounted system is a self-contained, portable industrial unit with integrated equipment mounted on a steel frame, allowing for easy transport, installation, and operation.

They offer portability, faster installation, reduced costs, simplified maintenance, and flexibility to customize and scale.

Common industries include oil and gas, chemical processing, water treatment, power generation, and food and beverage manufacturing.

Yes, they are highly customizable to fit specific operational needs, site constraints, and regulatory requirements.

Because they are fully assembled and tested off-site, installation time on-site is significantly reduced, speeding up project completion.

Skids can be engineered to meet all relevant codes and safety regulations, including ASME, API, and local standards.

Routine inspections and servicing of individual components are simplified due to the modular design, often allowing off-site maintenance.

Typically via truck or flatbed trailer, and lifted by cranes or forklifts into place due to their skid-mounted steel base.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.