What is ASME Code VIII for Pressure Vessels?

Understanding the Purpose of ASME Code VIII for Pressure Vessels

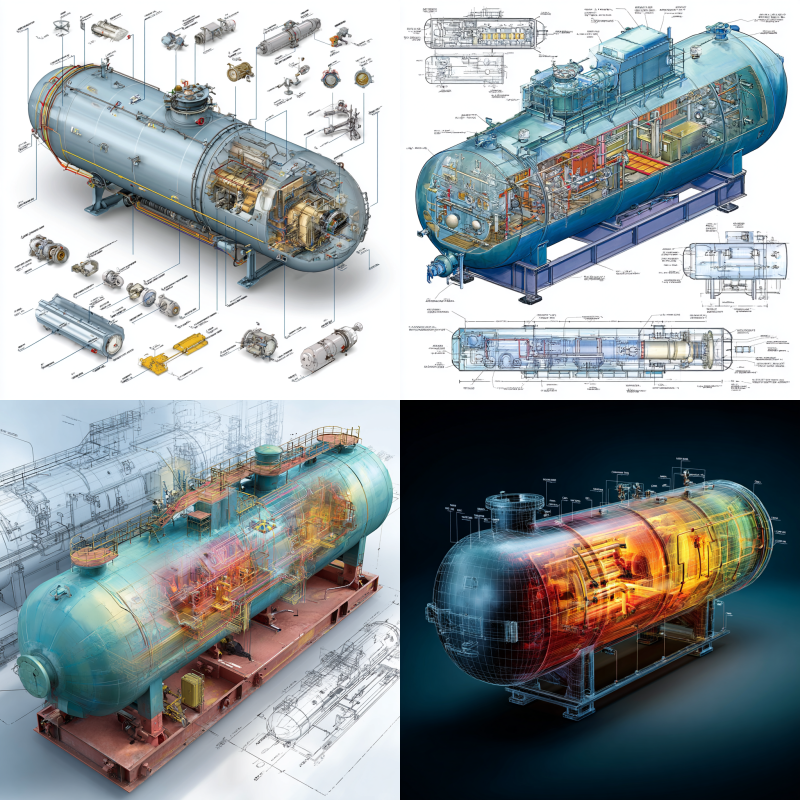

ASME Code VIII for pressure vessels is a vital part of the ASME Boiler and Pressure Vessel Code (BPVC). It provides essential guidelines for the design, construction, and inspection of pressure vessels, ensuring that they meet safety and quality standards required in various industries. Pressure vessels are essential to many industrial operations, from chemical processing to oil and gas production, food manufacturing, and energy generation. These containers hold gases or liquids at high pressures, making them inherently hazardous if not properly engineered.

That’s where ASME Code VIII for pressure vessels comes into play.

Developed by the American Society of Mechanical Engineers (ASME), this code is part of the ASME Boiler and Pressure Vessel Code (BPVC)—a globally recognized standard that ensures the safe design, fabrication, and inspection of pressure-retaining equipment. Specifically, Section VIII focuses on pressure vessels and offers detailed criteria for their safe construction and use.

First issued in 1914, the ASME BPVC has evolved through decades of technological advancement, field experience, and collaborative research. It’s updated every two years to accommodate changes in engineering knowledge, materials, and safety protocols. The goal? Prevent accidents, reduce liability, and provide a framework for universal compliance.

By enforcing rigorous design and manufacturing standards, ASME Code VIII protects both people and property, minimizing the risk of catastrophic failure, explosions, and downtime. Whether you’re a plant engineer, manufacturer, or project owner, understanding this code is not just good practice—it’s often a regulatory requirement.

The Three Divisions of ASME Code VIII

Section VIII of the ASME BPVC is divided into three distinct divisions, each serving different pressure ranges and use cases. Understanding the difference is key to selecting the right design and fabrication approach for your application.

Division 1: The Workhorse of Pressure Vessels

Division 1 is the most widely used and applies to pressure vessels that operate at pressures up to 3,000 psi. It provides general rules and is known for its simplicity and flexibility, making it suitable for a broad range of industrial applications.

Key features include:

- Use of design-by-rule methodology

- Widely accepted and understood by inspectors and engineers

- Cost-effective for standard pressure vessels

Division 1 is ideal for manufacturers and facilities seeking a balance between safety, cost, and versatility.

Division 2: Enhanced Safety and Efficiency

Division 2, often referred to as the “Alternative Rules”, applies to vessels with higher internal pressures or where efficiency and material optimization are important. It allows for design-by-analysis approach, which involves detailed stress evaluations, finite element analysis, and fatigue assessments.

Benefits include:

- Reduced wall thickness due to more accurate stress analysis

- Cost savings on materials for large or high-pressure vessels

- Enhanced fatigue resistance

This division is a go-to for industries requiring precision and optimization, such as aerospace, offshore energy, and advanced manufacturing.

Division 3: Ultra-High Pressure Applications

Division 3 is the most stringent and covers pressure vessels designed to operate above 10,000 psi (69 MPa). It is primarily used in high-pressure chemical reactors, research laboratories, and nuclear facilities.

Highlights include:

- Advanced design requirements

- Strict material testing and quality control

- Enhanced inspection protoco

Division 3 compliance is essential for ultra-high-pressure environments where even minor flaws can lead to catastrophic outcomes.

Key Requirements in ASME Code VIII

To ensure uniformity and safety, ASME Code VIII outlines specific requirements across multiple stages of pressure vessel development. These include:

1. Design and Engineering Standards

- All vessels must be designed to withstand internal and external pressures under normal and fault conditions.

- Stress calculations, corrosion allowances, and safety factors are clearly defined.

- Each division specifies methodologies (design-by-rule or design-by-analysis).

2. Material Selection and Qualification

- Only materials listed and approved by ASME can be used.

- Each material must have documented mechanical properties, traceability, and chemical composition.

- Material testing includes tensile strength, impact resistance, and hardness testing.

3. Fabrication Techniques

- Welding must follow procedures approved under ASME Section IX.

- Welders must be certified for specific processes and materials.

- Dimensional tolerances and joint configurations are tightly controlled.

4. Inspection and Testing

- Non-destructive examinations (NDE) such as radiography, ultrasonic testing, and dye penetrant testing are often required.

- Hydrostatic testing is standard to check vessel integrity under pressure.

- Third-party inspectors, often from Authorized Inspection Agencies (AIA), ensure code compliance before final certification.

5. Certification and Stamping

- Upon successful inspection, the vessel receives a U-Stamp or U2-Stamp, depending on the applicable division.

- A Manufacturer’s Data Report must be filed with the National Board of Boiler and Pressure Vessel Inspectors.

Want help with pressure vessel fabrication or compliance? Our team at Red River can guide you from design to delivery.

Why Compliance with ASME Code VIII Matters

You might ask: “Why go through all this effort?” The answer lies in the critical importance of safety, legal compliance, and trust.

Enhanced Safety

Pressure vessels hold substances that can reach extreme temperatures and pressures. Failure to adhere to proper design standards can result in:

- Explosions

- Leaks of toxic substances

- Severe injury or loss of life

ASME Code VIII reduces these risks by enforcing engineering discipline and testing rigor.

Legal and Regulatory Compliance

In many jurisdictions, compliance with ASME standards is mandatory. Regulatory bodies like the Occupational Safety and Health Administration (OSHA) and local governments often adopt ASME BPVC standards into law.

Non-compliance can result in:

- Fines and shutdowns

- Civil or criminal liability

- Loss of business licenses or certifications

Competitive Advantage and Global Recognition

Adhering to ASME Code VIII demonstrates:

- Commitment to industry best practices

- Quality assurance to clients and partners

- Eligibility for international markets that require ASME-certified vessels

Insurance and Risk Management

Insurers may require ASME certification as part of their underwriting criteria. Certified vessels:

- Are easier to insure

- Have fewer claims

- Lower long-term operating costs

The Role of ASME Code VIII in Pressure Vessel Integrity

ASME Code VIII for pressure vessels isn’t just a guideline—it’s the industry backbone for pressure vessel safety and performance. With clear divisions to match various pressure ranges and thorough specifications for design, testing, and compliance, this code ensures that pressure vessels perform safely and reliably in critical environments.

For companies operating in high-risk industries, embracing ASME Code VIII is more than compliance—it’s a strategic decision that protects people, property, and brand reputation. Whether you’re designing your first vessel or upgrading existing systems, understanding and applying this code is vital to long-term success.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Frequently Asked Questions (FAQ)

1. What is the ASME Boiler and Pressure Vessel Code?

The ASME BPVC is a set of engineering standards that ensure the safe design, manufacture, and inspection of boilers and pressure vessels. It’s updated every two years and is widely adopted across industries.

2. What does ASME Code VIII cover specifically?

ASME Code VIII deals with the design, materials, fabrication, inspection, and certification of pressure vessels. It ensures vessels can withstand the internal pressures they are subjected to in service.

3. How is Division 1 different from Division 2?

Division 1 uses a design-by-rule approach and is more general. Division 2 uses a design-by-analysis approach, allowing for thinner walls and optimized materials, but requires more detailed calculations and analysis.

4. Who must comply with ASME Code VIII?

Anyone involved in the design, manufacturing, or inspection of pressure vessels in regulated industries must follow ASME Code VIII to meet safety and legal requirements.

5. Is ASME Code VIII a legal requirement?

In many areas, yes. While ASME is a private organization, its codes are frequently adopted into law by regulatory agencies like OSHA and local governments.

6. What is the ASME U-Stamp?

The U-Stamp is a certification mark provided by ASME indicating that a pressure vessel has been built in compliance with Code VIII, Division 1.

7. What testing is required under ASME Code VIII?

Standard tests include hydrostatic pressure testing, radiographic weld inspection, and other non-destructive examinations (NDE) to confirm vessel integrity.

8. Can ASME-certified vessels be used internationally?

Yes, many countries recognize ASME standards. In fact, some international markets require ASME certification to approve equipment for use or import.

Key Takeaways

- ASME Code VIII ensures pressure vessels are designed and manufactured safely.

- It consists of three divisions, each suited for different pressure ranges and complexities.

- Code VIII outlines comprehensive standards for design, materials, fabrication, inspection, and certification.

- Compliance reduces legal risk, enhances operational safety, and opens doors to global markets.

- Partnering with a trusted fabricator like Red River ensures full code adherence and long-term vessel reliability.

Related Blog Post

- Why is ASME Code used?

- What are ASME and ANSI codes?

- What is ASME Code VIlI for pressure vessels?

- What is ASME Boiler and Pressure Vessel Code IX?

- What is the minimum size for ASME pressure vessel?

- What is the maximum pressure vessel limit for ASME?

- What is ASME boiler and pressure vessel code B31 1?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No pillar keyword set for this post.

About Author