Storage tanks are essential for holding a variety of substances. Consequently, our method for constructing these vessels is rooted in a deep understanding of their capabilities and the industries they serve. By leveraging our expertise, we ensure that each storage tank meets the highest standards of durability and functionality.

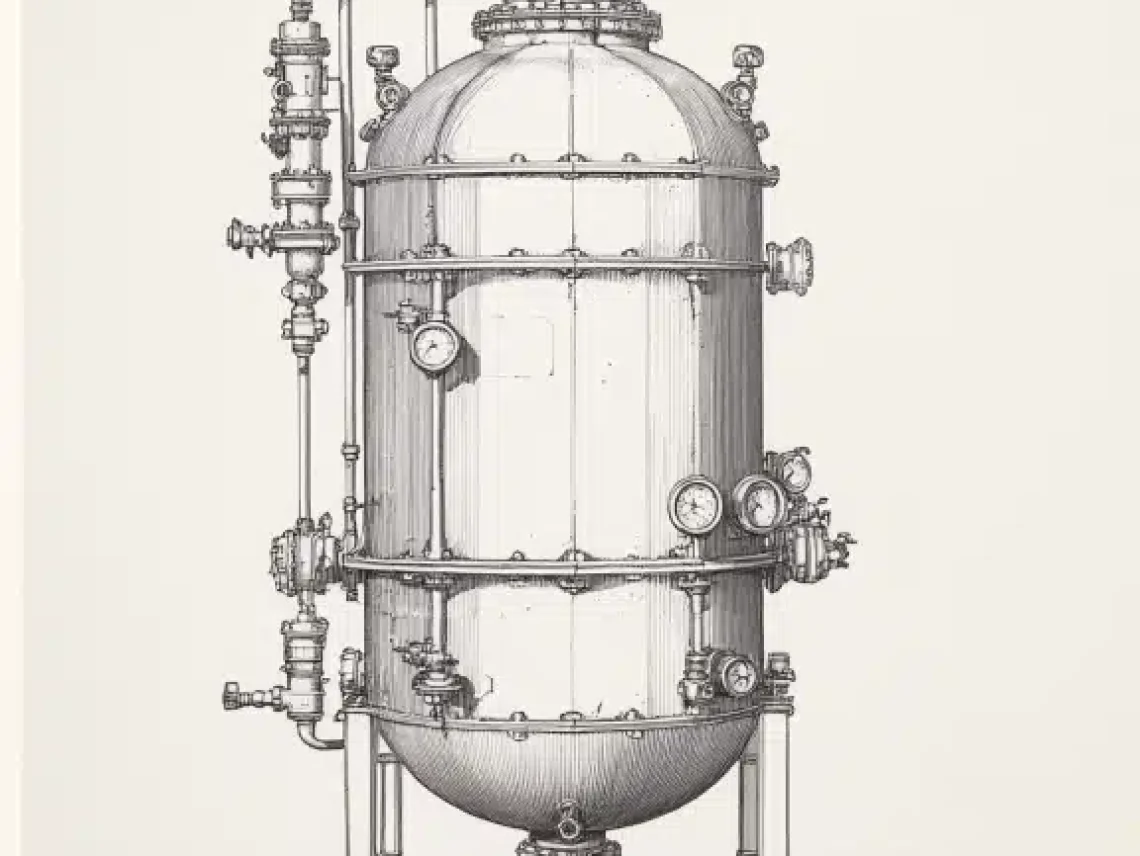

Heat exchangers, along with every other type of pressure vessel, are pivotal in energy conversion methods. Therefore, our design and fabrication techniques are carefully tailored to fulfill specific operational requirements. As a result, we emphasize efficiency and reliability, ensuring that our heat exchangers perform optimally in demanding environments.

Autoclaves are pressure vessels primarily used for sterilization tactics. In industries where sterility is paramount, our autoclaves stand out due to their sturdiness and exceptional performance. Consequently, they provide reliable and effective sterilization, making them indispensable in critical applications.

We utilize a variety of substances, including carbon steel and stainless steel. As a result, our pressure vessels are designed to withstand the specific demands of various working environments. Additionally, by selecting high-quality materials, we enhance the durability and longevity of our products.

Our workforce is extensively trained in modern welding processes. Because of this expertise, we can confidently tackle projects of any complexity with precision and efficiency. Furthermore, our commitment to continuous improvement allows us to adopt the latest fabrication advancements, ensuring top-tier results.

At Red River, quality is not just a buzzword—it’s a foundational principle. Accordingly, our stringent quality control measures guarantee that every vessel meets or exceeds ASME standards. Ultimately, this commitment to excellence ensures that our customers receive pressure vessels that perform reliably under all conditions.

The layout of a pressure vessel is not only about protection and efficiency but also about overall capability. Therefore, our team’s expertise in vessel geometry ensures superior performance under pressure. By carefully considering each design element, we optimize both functionality and safety.

Thickness plays a crucial role in pressure vessel design. At Red River, we carefully calculate the appropriate balance among thickness, material strength, and operational requirements. As a result, our vessels can withstand extreme conditions while maintaining structural integrity. Furthermore, this attention to detail ensures compliance with industry standards and enhances overall reliability.

At Red River, safety is embedded in our DNA. Consequently, we incorporate robust protection factors into our design calculations to enhance both durability and reliability. Additionally, by continuously refining our safety measures, we ensure that our pressure vessels meet the highest performance standards in demanding applications.

The choice of materials for pressure vessels is inspired by using several key elements, inclusive of the type of substance being contained (gas, liquid, risky materials), the working temperature and pressure, corrosion considerations, and the precise enterprise standards. Material electricity, durability, and compatibility with the contents are paramount. For example, stainless steel is preferred for its corrosion resistance, whilst carbon metal is probably chosen for its energy and fee effectiveness. Advanced composites also are used for her lightweight and excessive-strength houses.

Design standards together with the ASME Boiler and Pressure Vessel Code provide a comprehensive framework for the safe design, fabrication, inspection, and checking out of pressure vessels. These requirements cover fabric choice, design calculations, production techniques, and non-adverse testing strategies to ensure vessels can face up to operational pressures and temperatures without failure. Compliance with those requirements minimizes risks of accidents, ensuring the protection and reliability of pressure vessels in all packages.

Yes, pressure vessels can be custom-designed to meet particular operational requirements. This customization can consist of dimensions, fabric selection, inner additives, and unique coatings or linings to handle particular materials or working conditions. Custom layout allows for optimization of overall performance, performance, and safety, catering to the specific demanding situations of various industries.

Regular inspection and maintenance are critical for the lengthy-time period safety and functionality of pressure vessels. Inspections assist in discovering potential issues which include corrosion, fabric fatigue, or damage that could cause failure. Maintenance activities, consisting of cleaning, upkeep, and element replacements, make certain that vessels keep functioning adequately at their greatest performance levels. A nicely-maintained pressure vessel has a longer carrier life and reduces the threat of accidents.

Innovations in generation are considerably impacting pressure vessel production by introducing more green design software programs, advanced materials, and automated fabrication tactics. These improvements permit the introduction of lighter, more potent, and more corrosion-resistant vessels. Additionally, the usage of digital twins and predictive upkeep technologies can beautify the operational safety and sturdiness of pressure vessels.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.