Table of Contents

ToggleA closed pressure vessel, at its core, is a sealed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. As a result, these vessels play a pivotal role in numerous industries, ensuring that substances within are maintained at desired pressures. Consequently, this often leads to the generation of steam or the containment of various gases. At the same time, Red River LLC has been at the forefront of crafting these vessels with precision. Moreover, we ensure they stand the test of time and serve their purpose efficiently.

Steam generation is not just about boiling water. On the contrary, it’s a science and an art, deeply intertwined with the progress of various industries. For instance, from power generation to mineral extraction, and from biogas production to commercial works, steam is the driving force that powers machinery, facilitates processes, and ensures that industries run smoothly. Therefore, the methods used by closed-pressure vessels to create steam, such as the techniques for generating steam in a closed-pressure environment, are crucial for the efficiency and safety of these processes.

In addition, steam generation techniques in airtight pressure containers have revolutionized industries, making processes faster, safer, and more efficient. At Red River LLC, we understand the intricacies of this process and the science behind steam production in closed-pressure vessels. Thus, our commitment to American values, combined with our dedication to safety and quality, ensures that our pressure vessels are not just containers but solutions that drive industries forward.

At Red River LLC, we pride ourselves on being more than just a manufacturer. We are partners in progress, innovators in the field, and staunch believers in American values. Our expertise in pressure vessel technology is backed by a legacy of morals, work ethic, and a reputation built on trust. We serve a diverse range of industries, from oil and gas to power generation and biogas. Our clients, ranging from international giants to budding startups, trust us with their most valuable projects, and we never let them down.

Our dedication to safety goes beyond mere compliance. We believe in fostering a culture where safety is embedded in every operation, every process, and every product. Our closed pressure vessels are a testament to this commitment, ensuring efficient steam production when sealed, and showcasing innovations in steam generation within closed pressure systems.

When you partner with Red River LLC, you’re not just getting a product; you’re getting a promise. A promise of quality, reliability, and a handshake that means we’ll look you in the eye and do what we say. With Red River LLC, you’re not just another customer; you’re family. And for family, we bring nothing but the best. So, if you’re looking for a partner who understands your industry, shares your values, and prioritizes safety, Red River LLC is the one for you. Reach out to us, and let’s build the future together.

Steam formation is a phase transition where water, upon receiving adequate heat, turns into vapor. This transformation is fundamental in many industrial processes, harnessing the latent heat of vaporization.

Several factors, including water quality, heat source efficiency, and vessel design, play crucial roles in determining the rate and quality of steam produced.

A controlled environment ensures consistent steam quality, prevents impurities, and optimizes energy consumption, making processes predictable and efficient.

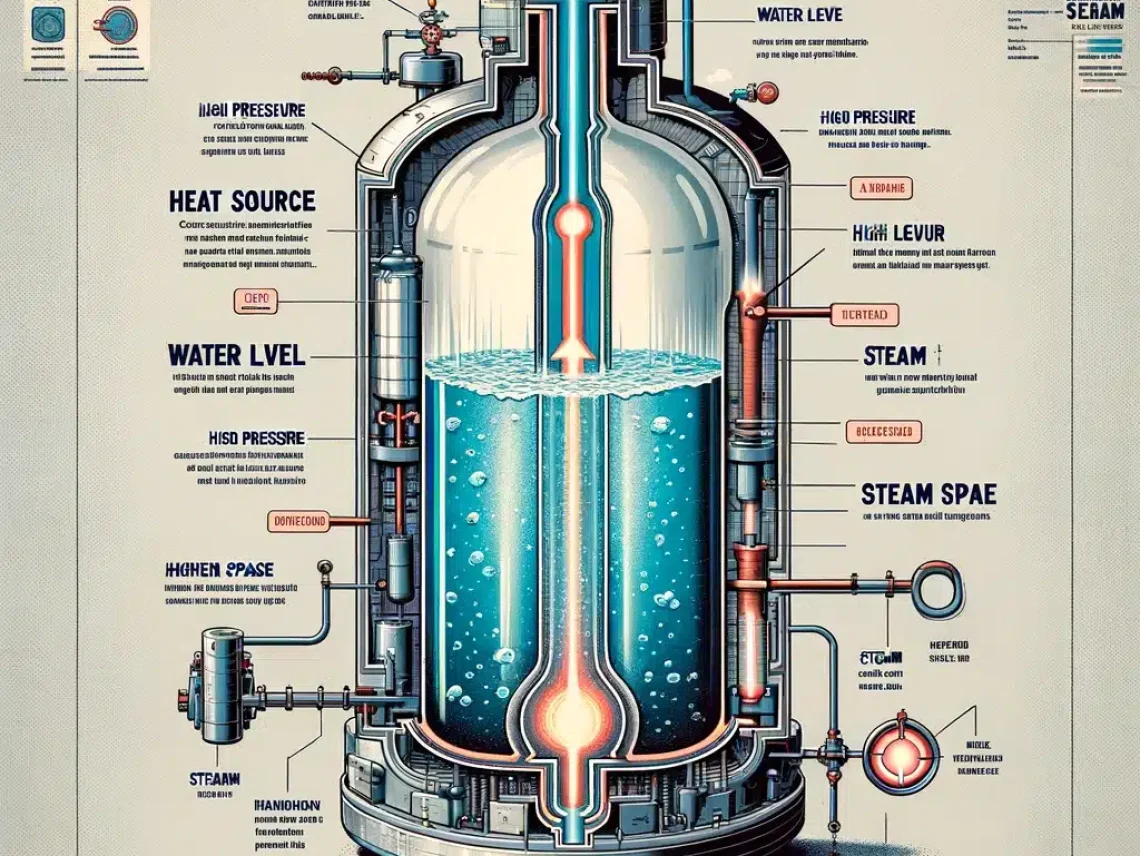

In closed pressure vessels, steam is generated by heating water under pressure. This setup raises the boiling point of water, enabling the production of high-temperature steam, which is essential for many industrial applications such as power generation, heating processes, and chemical reactions. The pressurized environment in these vessels allows for greater control over the steam generation process, optimizing energy efficiency and ensuring consistent output, which is crucial for industrial operations that require steady heat sources.

Temperature and pressure are key variables in steam production within sealed vessels. As pressure increases, the boiling point of water also rises, allowing water to remain in liquid form at higher temperatures. This relationship enables the production of steam at much higher temperatures and pressures than would be possible in an open system. The ability to manipulate these variables provides greater control over steam quality, ensuring that it meets the specific requirements of various industrial applications, from sterilization in the medical field to electricity generation in power plants.

Modern advancements in steam generation within closed vessels have led to the incorporation of innovative materials and designs. For example, high-strength alloys and corrosion-resistant materials improve the vessel’s durability and efficiency. Additionally, the use of advanced heat transfer designs, such as coiled tubes or finned surfaces, enhances the rate of heat transfer to the water, reducing the time required to generate steam. These innovations contribute to energy conservation, safety, and operational efficiency, making closed pressure vessels more effective and reliable in demanding industrial environments.

Closed pressure vessels are engineered to maximize heat utilization, which makes them highly efficient in steam production. The sealed environment minimizes heat loss, allowing more of the energy applied to the vessel to be converted into steam. This results in faster steam generation with reduced energy consumption, translating into significant cost savings, particularly in large-scale industrial operations where steam is in constant demand.

One of the primary advantages of using closed pressure vessels is the enhanced safety they offer. The sealed system prevents contaminants from entering the vessel, protecting the purity of the steam. Moreover, by controlling and containing high pressures within the vessel, the risk of accidental explosions or uncontrolled steam releases is minimized. This containment ensures the safety of both equipment and personnel, which is especially important in environments where workers are in close proximity to high-pressure steam systems.

Closed pressure vessels contribute to sustainability by reducing energy waste and minimizing the environmental impact of industrial steam production. By maximizing energy efficiency, these vessels help lower fuel consumption and reduce emissions associated with steam generation. Additionally, the longevity and durability of modern pressure vessels mean fewer replacements and less material waste over time. This focus on efficient, sustainable steam generation supports eco-friendly industrial practices and helps companies meet environmental regulations and reduce their carbon footprint.

Vessels are often made of robust materials like stainless steel, ensuring durability and resistance to corrosion.

Innovative designs ensure even heat distribution, optimal pressure maintenance, and efficient steam release.

Regular checks on weld points, seals, and pressure gauges ensure vessel longevity and safe operations.

Steam, generated in closed vessels, drives turbines, facilitates chemical processes, and aids in manufacturing, making it indispensable in industries from textiles to petrochemicals.

Power plants harness steam’s energy, converting it into electricity. Closed vessels ensure high-pressure steam, optimizing turbine efficiency.

Steam is pivotal in HVAC systems, providing consistent heating in winter and aiding in cooling processes during summer.

Overpressure, corrosion, and scaling are challenges in closed systems, affecting efficiency and safety.

Our proactive diagnostics, regular maintenance, and expert teams ensure swift issue resolution, minimizing downtime.

With quality materials and advanced designs, our vessels guarantee durability, optimal performance, and extended lifespans.

While open vessels interact with the atmosphere, closed ones are sealed, offering controlled pressure environments.

Open systems are simpler but less efficient. Closed systems, though complex, offer higher efficiency and safety.

Closed vessels produce high-pressure steam, ensuring energy optimization and consistent output.

“Our partnership with Red River LLC transformed our operations, thanks to their top-notch vessels.”

A textile company boosted its efficiency by 20% using our vessels, highlighting our commitment to excellence.

“Red River LLC sets the gold standard in pressure vessel manufacturing.” – Industry Analyst

A closed-pressure vessel is designed to contain and manage steam under pressure. Its primary purpose in steam generation is to heat water in a sealed environment, allowing it to reach temperatures above its normal boiling point. This results in the production of high-pressure steam, which is more energy-dense and efficient for various industrial applications.

Closed pressure vessels are generally more efficient than open systems. In a sealed environment, there’s minimal energy loss, ensuring that most of the heat applied to the system is used for steam generation. Additionally, closed systems can produce steam at higher pressures and temperatures, making the steam more energy-dense and suitable for tasks requiring more power.

While closed pressure vessels are designed with safety in mind, they are not without risks. The containment of steam under high pressure can lead to potential hazards if the vessel is not properly maintained or if safety protocols are not followed. Regular inspections, adherence to industry standards, and safety training are essential to mitigate these risks.

The quality of water plays a significant role in steam generation. Impurities in water, such as minerals or contaminants, can lead to scaling or corrosion inside the vessel. This not only reduces the efficiency of steam generation but can also compromise the integrity of the vessel over time. Using treated or distilled water can help maintain the efficiency and longevity of the system.

Recent advancements in steam generation focus on improving efficiency, safety, and environmental impact. Innovations include the use of advanced materials that reduce heat loss, computerized control systems for precise temperature and pressure management, and waste heat recovery systems that capture and reuse heat, reducing energy consumption. Additionally, there’s a growing emphasis on sustainable practices, such as the integration of renewable energy sources in steam generation.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.