Understanding Forged Pressure Vessels: An Overview

Table of Contents

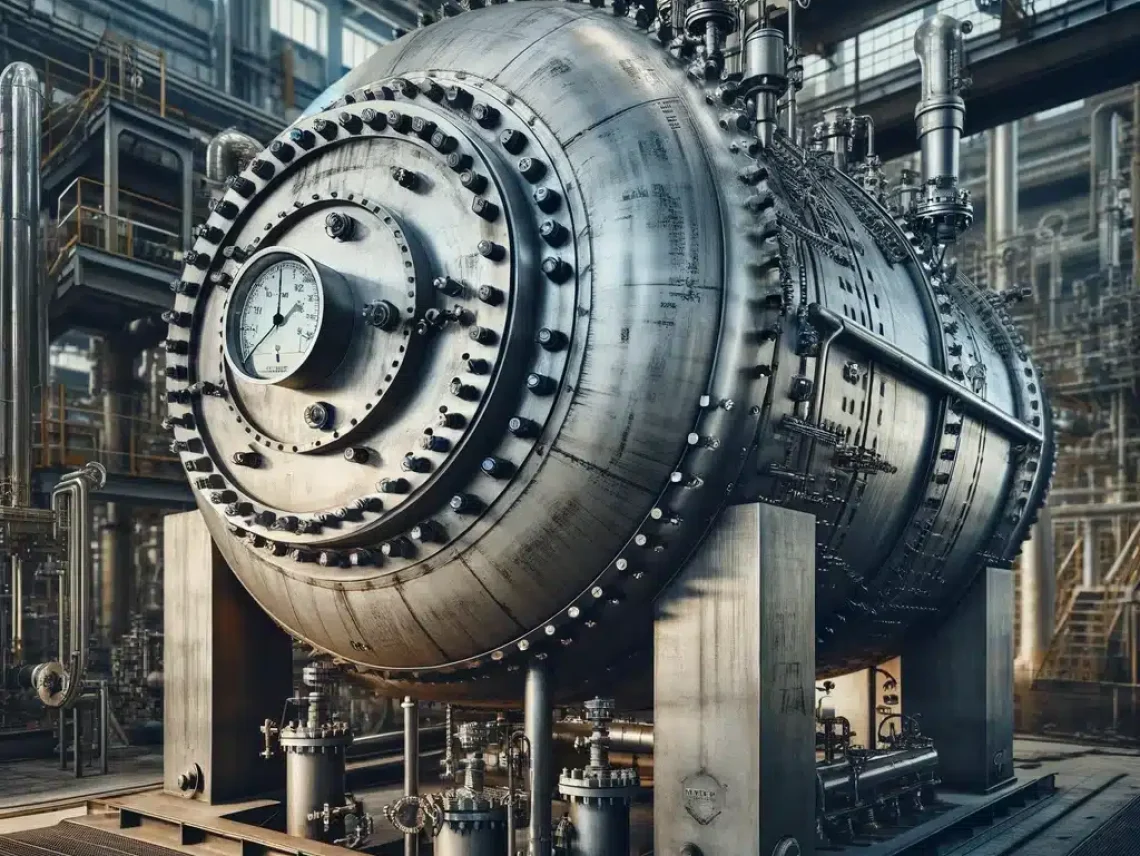

ToggleIntroduction to a Forged Pressure Vessel

At Red River LLC, we understand that the heart of many industries lies in the robustness of their systems. A solid pressure vessel is more than simply a part of a system; it is an essential asset that ensures the safety and efficiency of operations throughout various sectors, including oil and gas, energy generation, and biogas. Furthermore, forged pressure vessels, recognized for their energy and durability, are crucial for managing severe pressures and temperatures. Therefore, our dedication at Red River is to offer you vessels that not only meet but exceed industry standards.

The History and Evolution of Pressure Vessel Forging

Tracing back to the Industrial Revolution, the forging of pressure vessels has evolved drastically. Over the years, we have honored these rich traditions by blending traditional craftsmanship with modern technology. As a result, our journey in pressure vessel manufacturing reflects a legacy of innovation and excellence. Today, we’ve grown from producing simple forged steel pressure vessels to manufacturing complex, custom-designed pressure tanks, adapting to the ever-changing needs of the industries we serve.

Key Components of a Forged Pressure Vessel

The integrity of a forged pressure vessel lies in its components. From the shell to the heads, nozzles, and fittings, every detail of our vessels is crafted with precision and care. At the same time, we pay meticulous attention to each aspect, ensuring that every factor meets the highest standards of safety and performance. Consequently, our industrial pressure tanks are known for their reliability and durability.

Materials Used in Forged Pressure Vessels

The selection of materials is paramount in the manufacturing of pressure vessels. For instance, we use a wide range of materials, including carbon steel and stainless steel, to cater to various industrial needs. Moreover, our expertise in selecting the proper material for high-pressure vessels ensures solutions that withstand the toughest conditions. Thus, we guarantee both sturdiness and reliability in every product we deliver.

Comparing Forged and Fabricated Pressure Vessels

Understanding the distinction between forged and fabricated pressure vessels is essential when choosing the right equipment for your needs. For example, forged vessels, known for their uniformity and strength, are ideal for high-pressure applications. On the other hand, fabricated vessels offer greater flexibility in design. At Red River, we specialize in both, providing a wide range of options, from heavy-duty forged pressure chambers to custom-fabricated solutions.

Section 2: Types and Applications

Various Types of Forged Pressure Vessels

Red River LLC offers a diverse range of forged pressure vessels, including high-pressure forged vessels, industrial cast pressure tanks, and custom-designed solutions. Each option is meticulously engineered to meet unique industry requirements, ensuring optimal performance across varying operational conditions.

Industrial Applications of Forged Pressure Containers

Our forged pressure vessels play a crucial role in industries such as oil and gas, power generation, and chemical processing. In these sectors, they are designed to withstand extreme conditions, ensuring both protection and efficiency.

Forged Pressure Vessels in Energy and Power Generation

In energy and power generation, forged pressure vessels are indispensable. For instance, they ensure operational efficiency and safety by enduring the rigorous demands of power plants and energy facilities. As a result, they contribute to the stability of critical energy systems.

The Role of Forged Vessels in the Chemical Industry

Our forged vessels are critical within the chemical industry, and known for their power and corrosion resistance. They adequately incorporate and method diverse chemical substances, contributing to the enterprise’s achievement.

Custom Forged Pressure Vessels for Specialized Needs

We concentrate on custom answers, tailoring our vessels to meet precise dimensions, pressures, or environmental conditions, ensuring top-quality overall performance and protection.

Section 3: Manufacturing Process

Steps in Manufacturing Forged Pressure Vessels

Our manufacturing system entails precise layout, fabric selection, forging, and assembly. Each step is meticulously accomplished to ensure the highest excellent of our vessels.

Quality Control in Forging Pressure Vessels

We implement rigorous fine manipulation measures at every degree of production. This guarantees that every vessel is faultless and meets enterprise standards.

Innovations in Forging Technology for Pressure Vessels

We constantly innovate our forging techniques, embracing technological improvements to beautify the fine of our products.

Safety Standards and Compliance in Forging

Safety is a cornerstone of our operations. We adhere to strict safety requirements and compliance protocols to ensure the well-being of our crew and the excellence of our vessels.

The Future of Forging Technology in Pressure Vessel Manufacturing

We are constantly searching ahead, expecting destiny traits in forging technology to stay at the vanguard of the enterprise.

Section 4: Design and Engineering

Principles of Designing Forged Pressure Vessels

Our layout standards recognize growing vessels that can be efficient and secure, assembly the specific needs of our customers.

Engineering Considerations for High-Pressure Forged Vessels

We don’t forget different factors together with cloth selection, pressure scores, and environmental conditions in our engineering process.

Custom Design Solutions for Forged Pressure Vessels

We offer custom layout solutions, making sure that each vessel is ideally suited to the client’s requirements.

Advanced Simulation and Modeling in Vessel Design

We use superior simulation and modeling techniques to optimize the design of our vessels, ensuring their reliability and safety.

Case Studies: Innovative Forged Vessel Designs

Our portfolio consists of revolutionary designs that showcase our capability to fulfill complicated and tough necessities.

Section 5: Benefits and Challenges

Advantages of Using Forged Pressure Vessels

Our forged pressure vessels provide several benefits, which include superior power, durability, and reliability.

Overcoming Challenges in Forging Pressure Vessels

We cope with numerous demanding situations in forging, ensuring that our vessels meet the very best requirements of high quality and safety.

Cost-Benefit Analysis of Forged vs. Other Vessels

We provide an in-depth price-gain analysis, demonstrating the lengthy-term fee of selecting solid vessels.

Maintenance and Longevity of Forged Pressure Vessels

Our vessels are designed for longevity, requiring minimum maintenance whilst imparting maximum performance.

Addressing Environmental Concerns in Forging Processes

We are dedicated to environmentally accountable production practices, constantly searching for ways to reduce our environmental effects.

Section 7: Purchasing and Customization

How to Choose the Right Forged Pressure Vessel

At Red River LLC, we adhere to international standards for cast pressure vessels, ensuring our products meet worldwide protection and exceptional benchmarks. This commitment positions us as a relied-on international supplier.

Customization Options in Forged Pressure Vessels

We navigate the complex panorama of regulatory compliance in vessel production with know-how, making sure that every vessel we produce meets the desired felony and safety requirements.

Working with Manufacturers for Custom Needs

Our certification system is rigorous, involving thorough inspections and trying to certify that our vessels meet all enterprise standards, presenting our clients with the guarantee of protection and high quality.

Cost Considerations in Purchasing Forged Vessels

Regulations significantly from our forging practices. We constantly replace our strategies to align with cutting-edge regulatory changes, making sure compliance and safety.

Ensuring Quality and Durability in Your Purchase

Staying abreast of enterprise standards and pleasant practices is a cornerstone of our operation, making sure that we deliver the simplest the excellent in forged pressure vessel manufacturing.

Section 8: Case Studies and Testimonials

Success Stories: Businesses Using Forged Pressure Vessels

Choosing the proper solid pressure vessel includes understanding particular wishes and packages. We manual our clients through this process, making sure they make informed decisions.

Testimonials from Red River LLC Clients

Our customization alternatives are big, permitting clients to tailor vessels to their specific requirements, whether it’s length, material, or design specifications.

Innovative Projects Featuring Forged Pressure Vessels

We paint closely with our clients to understand their custom wishes, making sure that the final product aligns perfectly with their necessities.

Lessons Learned from Forged Vessel Implementations

We offer transparent cost issues, assisting clients in understanding the value and long-term benefits of investing in our high-quality solid vessels.

How Red River LLC Delivers Excellence in Forged Vessels

Quality and durability are our guarantees. We make sure that each vessel purchased from us stands the check of time and meets the best quality standards.

Need a reliable partner?

Frequently Asked Questions (FAQs) About Pressure Vessels

1. What are the key factors to consider when selecting materials for a pressure vessel?

When selecting materials for a pressure vessel, it’s crucial to consider factors such as the operating environment (temperature and pressure), the medium being contained (whether it’s corrosive or non-corrosive), and the vessel’s intended lifespan. Materials commonly used include carbon steel for its strength and affordability, and stainless steel for its corrosion resistance. The choice of material significantly impacts the vessel’s durability, maintenance requirements, and overall safety.

2. How do pressure vessel design standards ensure safety and reliability?

Pressure vessel design standards, such as those set by the American Society of Mechanical Engineers (ASME), ensure safety and reliability by providing guidelines on factors like material selection, design, fabrication, inspection, and testing. These standards help mitigate risks associated with high-pressure operations by ensuring that vessels can withstand the operational stresses they will encounter. Compliance with these standards is not just about meeting legal requirements but also about ensuring the longevity and safe operation of the vessel.

3. What are the differences between vertical and horizontal pressure vessels, and how does orientation impact performance?

Vertical and horizontal pressure vessels differ mainly in their orientation, which can impact their performance and suitability for certain applications. Vertical vessels typically have a smaller footprint and are preferred when space is limited. They are often used for applications involving phase separation. Horizontal vessels, on the other hand, offer easier access for maintenance and are generally better for applications involving large-volume storage. The choice between vertical and horizontal orientation depends on the specific operational needs, space constraints, and the nature of the materials being stored or processed.

4. Can pressure vessels be customized for specific industrial applications, and what are the limits of customization?

Yes, pressure vessels can be extensively customized to meet specific industrial applications. Customization can include size, shape, material, internal components, and external attachments. However, the limits of customization are generally dictated by safety standards, material capabilities, and manufacturing technology. While customization allows for tailored solutions, it must always align with safety and performance standards to ensure the vessel’s integrity and functionality.

5. What are the emerging trends and technologies in pressure vessel manufacturing?

Emerging trends in pressure vessel manufacturing include the use of advanced materials like composites for lighter and stronger vessels and the integration of IoT (Internet of Things) for real-time monitoring and predictive maintenance. Additionally, there’s a growing emphasis on sustainable manufacturing practices and the use of renewable energy sources. Technological advancements in welding and fabrication are also enabling more precise and efficient production processes. These trends and technologies are driving the industry towards more efficient, safe, and environmentally friendly solutions.

Table of Contents

ToggleRelated Blog Post

- What is the vessel process?

- What is millwright fabrication?

- What is pipe fabrication work?

- What is the fabrication of ships?

- What is the role of vessel operations?

- What does a pressure vessel engineer do?

- How many elements are in a pressure vessel?

- How do you perform a pressure vessel inspection?

- Is a vital part of a pressure vessel fabricated by welding?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.