Understanding Maximum Allowable Working Pressure in Vessels

Table of Contents

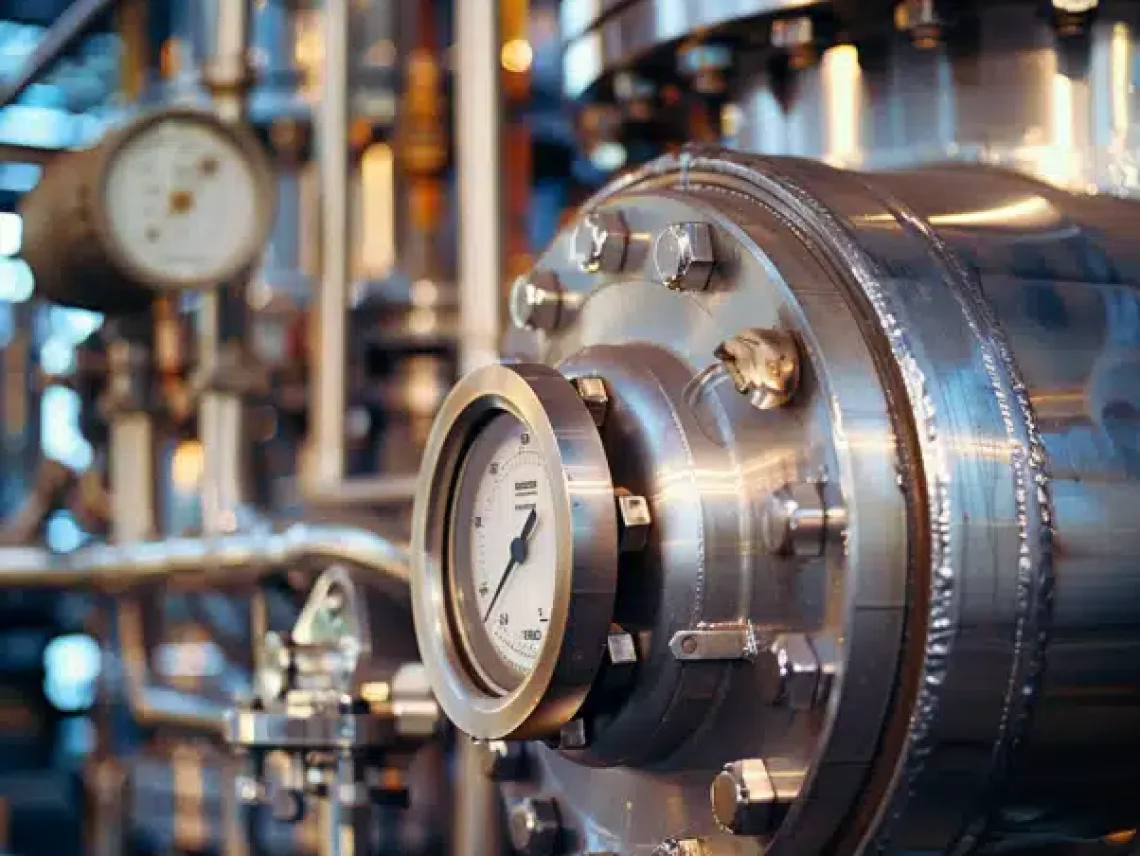

ToggleCalculating Maximum Allowable Working Pressure (MAWP): An Overview

Calculating MAWP is an art and science, combining advanced engineering standards with our large area experience. We keep in mind every factor – from fabric electricity to weld integrity – making ensure every vessel’s safety and overall performance.

Material Considerations in MAWP Calculation

We choose materials now not only for their electricity but for his or her compatibility with your specific utility, considering factors like corrosion, temperature, and pressure to ensure lengthy-term reliability.

The Role of Temperature and Corrosion Allowance

Temperature fluctuations and corrosive materials can affect vessel integrity. Our designs include allowances for these variables, making sure your vessel’s MAWP remains uncompromised over its lifespan.

Standards and Regulations Governing Maximum Allowable Working Pressure (MAWP)

ASME Boiler and Pressure Vessel Code

We do not just observe ASME requirements; we embody them in our work. Our adherence to those recommendations ensures that every vessel leaves our facility ready to meet the hardest demands.

International Pressure Vessel Standards

Our information goes past borders, with deep information on international requirements ensuring your vessels are compliant, regardless of where they operate.

Compliance and Certification for MAWP

Each vessel’s adventure through our facility ends with rigorous testing and documentation, providing you with the guarantee that your gadget is certified to operate at its certain MAWP.

Design Considerations for Pressure Vessels

Designing for Maximum Safety and Efficiency

Our design philosophy facilities on creating vessels that not most effectively meet your operational needs however achieve this with the best protection margins and performance.

Advanced Materials and Technologies in Vessel Design

We leverage the cutting-edge in cloth technology and production technologies, ensuring each vessel is optimized for performance and sturdiness.

Safety Protocols for Pressure Vessels

Routine Inspection and Maintenance Best Practices

We provide you with the expertise and tools to maintain your vessel’s integrity, making sure a long and productive career life.

Emergency Response Strategies for Pressure Vessel Failures

While we design for sturdiness, we additionally plan for the surprising, equipping you with techniques to reply efficaciously to any situation.

Need a reliable partner?

FAQ’s about Maximum Allowable Working Pressure (MAWP)

What factors determine the MAWP of a pressure vessel?

The Maximum Allowable Working Pressure (MAWP) of a pressure vessel is determined with the aid of numerous crucial elements, consisting of the material’s power, the thickness of the vessel’s walls, the temperature at which the vessel operates, and the effects of external and inner forces including weight and pressure exerted through the contents.

How do modifications in operating temperature affect the MAWP of a pressure vessel?

Temperature variations can substantially impact the MAWP of a pressure vessel because of the cloth’s thermal expansion and contraction. As temperature increases, the fabric’s capacity to resist pressure decreases, main to a decrease MAWP. Conversely, at decreased temperatures, materials can come to be brittle, additionally affecting the vessel’s pressure resistance.

Can the MAWP of a current pressure vessel be improved?

Increasing the MAWP of an existing pressure vessel is viable however involves thorough analysis and adjustments via licensed engineers. This procedure may include reinforcing the vessel’s partitions, upgrading substances, or converting additives like nozzles and flanges to withstand higher pressures. Any amendment needs to be meticulously examined and licensed to fulfill protection requirements earlier than the vessel can perform at a better MAWP.

What position does corrosion allowance play within the layout of pressure vessels?

Corrosion allowance is a critical element inside the layout of pressure vessels, accounting for the lack of cloth thickness through the years because of corrosion. By including more cloth thickness beyond what’s required to face up to the internal pressure, designers make certain that the vessel continues its structural integrity and MAWP at some stage in its expected service lifestyles, at the same time as corrosion happens.

How is compliance with ASME and different global requirements ensured in the course of the pressure vessel manufacturing method?

Compliance with the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, as well as other international standards, is ensured through a series of steps which include layout review, fabric choice, manufacturing process manipulation, and rigorous checking out. Certified engineers oversee the complete system, from preliminary design to the very last inspection, ensuring each aspect of the vessel meets the specified standards.

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.