Table of Contents

TogglePressurized Water Reactors (PWRs) are the world’s most common nuclear reactors, using highly pressurized water for efficient, stable, and safe power generation. Their advanced safety systems, dual-function coolant design, and low-carbon output make them the backbone of modern, sustainable nuclear energy. Emerging innovations like Small Modular Reactors (SMRs) continue to enhance their scalability and global relevance.

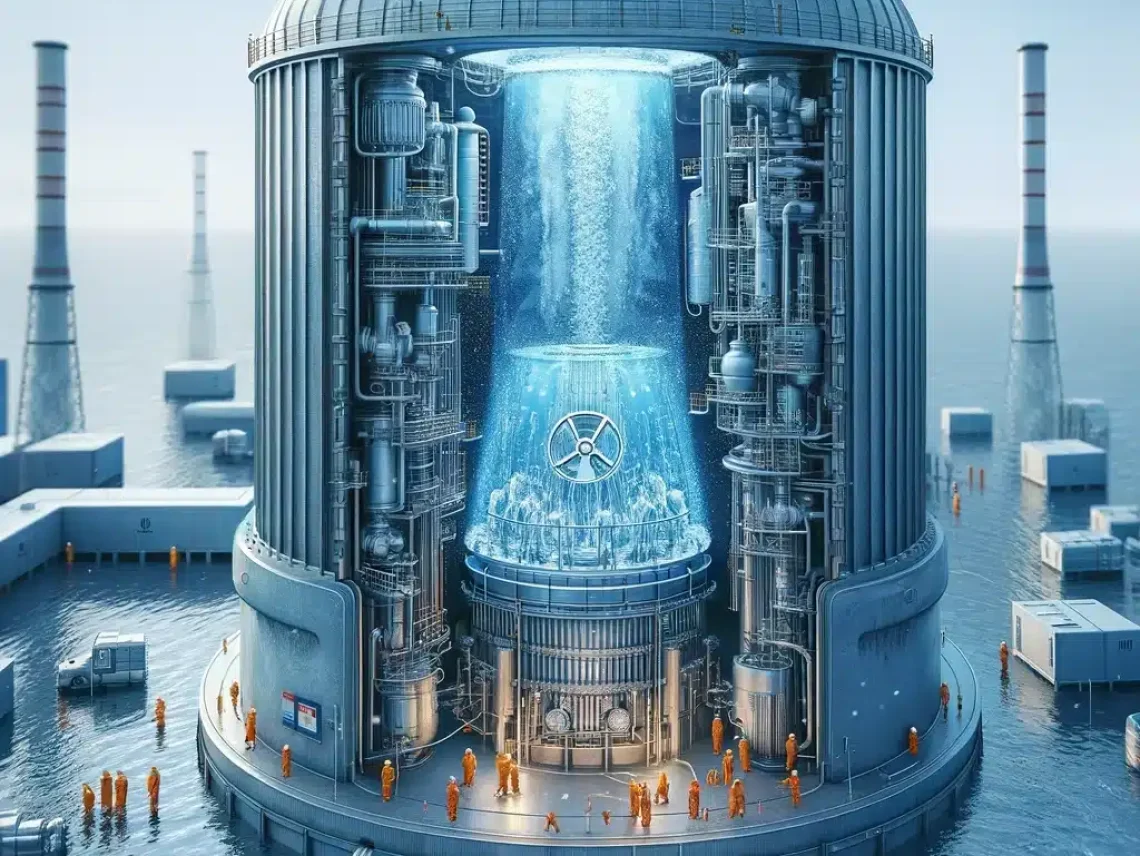

A pressurized water reactor (PWR) is the most widely used type of nuclear reactor in the world, known for its safety and thermal efficiency. At the heart of many power generation systems, the pressurized water reactor uses highly pressurized water as both a coolant and neutron moderator, allowing it to maintain high operating temperatures without boiling. This unique design enables the reactor to efficiently transfer heat and generate electricity with minimal environmental impact. At Red River LLC, we specialize in advanced pressure vessel manufacturing and understand how PWR technology integrates into modern energy infrastructure.

According to the University of Calgary’s Energy Education platform, PWRs account for the majority of nuclear reactors worldwide due to their reliability and proven safety record.

The journey of PWRs began in the mid-20th century, and since then, they’ve become a cornerstone in the nuclear energy sector. Initially developed for naval propulsion, their efficiency and safety features soon caught the attention of the power generation industry. Over the years, the technology has evolved, with continuous improvements enhancing its safety and performance metrics. At Red River LLC, we value the work ethic and dedication that has driven this evolution. Just as the pioneers of PWR technology were committed to innovation, we too are dedicated to pushing boundaries in the industries we serve, from oil and gas to power generation and beyond.

Pressurized Water Reactors (PWRs) are among the most widely used types of nuclear reactors worldwide. Their importance in the modern energy landscape is undeniable, thanks to their superior safety features and efficiency in power generation. Here’s why PWRs are a preferred choice in nuclear power:

Why should you choose a PWR for your energy needs?

One of the most remarkable advantages of Pressurized Water Reactors (PWRs) is their dual-function design. By using pressurized water as both a coolant and a neutron moderator, PWRs achieve optimal temperature control. This setup demands precision in the construction of reactor vessels especially in understanding the thickness of a reactor pressure vessel to withstand immense internal pressure while maintaining long-term safety.

Safety is the cornerstone of nuclear power, and PWRs are designed with multiple fail-safe mechanisms to ensure the containment of radioactive materials and prevent catastrophic events. Some of the key safety features include:

PWRs excel in performance because of their ability to operate at high pressures. This high-pressure operation eliminates the need for boilers or steam turbines, simplifying the system and improving efficiency. By directly producing steam at high pressure, PWRs offer a streamlined process that significantly reduces energy losses and enhances overall performance.

When it comes to choosing the right nuclear reactor technology, it’s essential to understand how Pressurized Water Reactors (PWRs) compare to other reactor types. Let’s dive into a few key comparisons:

Both PWRs and BWRs are light water reactors, meaning they both use water to cool the reactor and moderate neutrons. However, there are some notable differences:

While both reactors use nuclear fission to generate power, PWRs and Fast Breeder Reactors (FBRs) differ significantly in their designs and fuel cycles:

Heavy Water Reactors (HWRs) and Pressurized Water Reactors differ in their moderator material and design:

The thermal efficiency of a pressurized water reactor comes from its ability to operate at high temperatures without boiling the coolant. For a helpful breakdown of this process, view the U.S. Department of Energy’s infographic showing how PWRs convert nuclear heat into electricity.

One of the core design elements that set PWRs apart is pressurization. By pressurizing the water inside the reactor, PWRs prevent water from boiling, allowing the reactor to operate at higher temperatures (up to 320°C or 608°F) than non-pressurized systems. This enhances thermal efficiency and leads to a more stable and consistent power generation process, which is essential for long-term operation.

Higher Temperature, Higher Efficiency: The ability to achieve higher temperatures allows the reactor to convert more nuclear energy into usable electricity, improving overall efficiency.

The thermal design of a PWR maximizes the transfer of heat from the reactor core to the coolant. This design allows the reactor to reach optimal operational temperatures while ensuring that the energy generated is efficiently converted into electricity. The high thermal conductivity of the coolant ensures minimal energy loss, contributing to the overall efficiency of the reactor.

Efficient Energy Conversion: PWRs are designed to ensure that the thermal energy from the fission process is rapidly and effectively transferred to the steam generation system, which drives the turbines and produces electricity.

Coolants in PWRs are crucial for maintaining reactor temperature and ensuring safety. PWRs typically use water as a coolant, which serves two main functions:

PWRs come equipped with rapid shutdown systems, multi-layer containment barriers, and redundant cooling systems. These components are critical to preventing radiation leaks and structural compromise, especially under extreme thermal and pressure conditions. Learn more about our approach to high–pressure vessel risks and safety.

PWRs are equipped with multi-layered safety mechanisms and passive containment systems to prevent overheating or radiation leaks. These systems are regularly evaluated and improved in coordination with international agencies. For example, the IAEA’s safety improvement initiative offers detailed insights into how European PWRs are advancing safety standards through research and global collaboration.

PWRs are built with inherent safety features that ensure the reactor remains in a subcritical state, significantly reducing the risk of a nuclear meltdown. The design allows for the reactor to automatically regulate itself, maintaining a safe operational state even in extreme conditions.

PWRs come equipped with rapid shutdown systems that can instantly halt the nuclear fission process in the event of an anomaly. These procedures are designed to ensure that the reactor ceases operation immediately, preventing any unsafe accumulation of heat or radiation.

To prevent radiation leakage, PWRs are designed with multi-layered containment structures. These robust systems prevent any radioactive materials from escaping, ensuring both the safety of the personnel and the environment.

PWRs are a clean energy alternative that significantly reduces greenhouse gas emissions compared to traditional fossil fuel-based power sources. This makes them an essential part of the global effort to combat climate change and reduce the carbon footprint of energy generation. By relying on nuclear energy, PWRs provide a consistent, low-emission power source that contributes to a greener future.

Unlike fossil fuels, which are finite, PWRs rely on abundant nuclear fuel sources that can produce vast amounts of energy for decades. Their ability to generate energy sustainably ensures that growing energy demands can be met without depleting natural resources. Additionally, PWRs produce minimal waste compared to fossil fuel plants, helping create a sustainable energy cycle.

Modern PWRs are designed with cutting-edge waste management systems that handle radioactive waste efficiently and safely. These systems ensure the long-term disposal of nuclear waste in a controlled, secure manner, minimizing any environmental risks. As part of the nuclear fuel cycle, PWRs contribute to safe and efficient waste disposal, making them a more environmentally responsible option compared to other energy sources.

Pressurized Water Reactors (PWRs) are not just a theoretical solution; they have been successfully implemented in power plants worldwide, proving their effectiveness, reliability, and safety in large-scale energy production. Here are some examples of their successful application:

PWRs are the preferred choice for nuclear power plants globally, offering unmatched safety and efficiency. Their widespread use across diverse geographical regions underscores their capability to meet the energy demands of different nations while maintaining environmental standards.

Numerous energy plants across the globe have successfully implemented PWRs, setting new benchmarks in nuclear energy production. Here’s a closer look at some successful integrations:

Next-generation pressurized water reactor designs such as the AP1000 and VVER-1200 incorporate passive safety systems and modular construction techniques, reducing both cost and construction time. In parallel, small modular reactors (SMRs) based on pressurized water reactor principles are gaining traction as scalable solutions for decentralized energy needs. These innovations often rely on prefabricated assemblies and modular skid packages like those built through our capabilities in prefabrication, allowing faster deployment without compromising safety. As global energy demands rise, the pressurized water reactor continues to evolve as a cornerstone of sustainable, carbon-free power generation.

Transitioning to PWR technology is a significant step for any energy provider or industrial operation. Our comprehensive guide will walk you through the key stages of adopting PWRs, from initial feasibility assessments to final implementation. Here’s how we make your switch seamless:

Before committing to PWR technology, it’s crucial to evaluate its feasibility for your specific needs. At Red River LLC, we offer expert consultations to determine if PWR technology is the right fit for your energy production goals.

Switching to PWR technology is an investment that pays off in the long run. Our cost-benefit analysis weighs both the initial investment and the long-term financial benefits to give you a clear picture of the return on investment (ROI).

Transitioning to PWR technology involves a well-planned and systematic process. Here’s how we guide you through each phase:

The pressurized water reactor (PWR) has proven to be one of the most reliable and efficient technologies in the nuclear energy sector. With decades of successful operation, continuous design evolution, and adoption in advanced modular formats, PWRs remain central to the global transition toward clean and sustainable energy.

As industries and governments seek resilient, low-carbon power solutions, the PWR stands out for its safety record, scalability, and adaptability across both civilian and naval applications.

Whether you’re planning a new pressurized water reactor deployment or upgrading existing systems, Red River is your trusted partner for high-integrity pressure vessels, prefabricated skids, and modular systems. We don’t just build to spec we build for the future.

Contact us today to schedule a consultation or request a custom quote.

A pressure vessel is a specialized container designed to hold gases or liquids under pressure, significantly different from ambient conditions. These vessels are crucial in many industries, including:

Safety First: Pressure vessels are designed to contain hazardous substances safely, preventing leaks or explosions.

The material selection for pressure vessels is crucial due to the extreme operating conditions they endure, such as:

Both pressure vessels and boilers are designed to contain pressurized substances, but their purposes are different:

Pressure vessels are equipped with several safety measures to ensure their integrity:

Prefabrication is the process of assembling pressure vessel components off-site, offering numerous advantages:

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.