Table of Contents

ToggleIn the dynamic world of pressure vessel manufacturing, Type 4 pressure vessels have emerged as a game-changer. At its core, a Type 4 pressure vessel is a container specifically designed with a combination of composite materials and a plastic liner, ensuring optimal performance and safety. This unique design not only enhances its durability but also significantly reduces its weight, making it a preferred choice for many industries.

The journey of pressure vessel technology is a testament to human ingenuity and the relentless pursuit of excellence. From the rudimentary containers of the past to the sophisticated vessels of today, the evolution has been nothing short of remarkable. At Red River LLC, we’ve been at the forefront of this evolution, embracing each advancement and ensuring our clients benefit from the latest in pressure vessel engineering. Our dedication to American values, combined with our commitment to innovation, has positioned us as industry leaders. We’ve seen the transition from Type 1 vessels, which relied heavily on metals, to the composite wonders of Type 4. This journey has been fueled by a desire to serve industries like OIL AND GAS, POWER GENERATION, and BIOGAS with the best solutions available.

There are numerous reasons to opt for Type 4 pressure storage, and at Red River LLC, we believe in empowering our clients with knowledge. So, why do Type 4 pressure vessels stand out?

At Red River LLC, we’re not just manufacturers; we’re partners in your journey. Our clients, from startups to international giants, trust us because we deliver on our promises. We understand the value of a firm handshake and the importance of reputation. When you choose us, you’re not just getting a product; you’re becoming a part of a family that values trust, commitment, and the relentless pursuit of excellence. So, if you’re looking for a partner who understands the superiorities of Type 4 pressure containment systems and shares your core values, look no further. Red River LLC is here for you.

Type 4 pressure vessels are widely regarded for their outstanding safety features, which include a design that significantly reduces potential risks during operation. These vessels are engineered to minimize the likelihood of leaks, ruptures, and other safety hazards, thus creating a safer working environment for operators and industries handling volatile materials. This high level of safety reflects a dedication to robust engineering principles, making these vessels suitable for high-stakes applications where safety is a primary concern.

Type 4 pressure vessels are constructed from advanced composite materials, specifically chosen for their strength, resilience, and durability under demanding conditions. The use of composite materials ensures that these vessels can withstand extreme pressures and temperatures, maintaining their integrity even in challenging operational environments. This material choice not only contributes to their strength but also provides a level of resilience that extends the vessel’s lifespan, making them a cost-effective choice for industries requiring long-term reliability.

One of the notable benefits of Type 4 pressure vessels is their lightweight design, achieved through the use of composite materials. This reduced weight contributes to easier handling and installation, as well as improved transport efficiency, especially in applications where weight is a crucial factor. Additionally, the lighter design enhances operational efficiency, allowing for better performance without sacrificing structural integrity. Industries that rely on mobile or transportable equipment benefit significantly from this reduced weight, enabling them to optimize fuel usage and lower operating costs.

In the aerospace sector, the characteristics of Type 4 pressure vessels, such as their lightweight structure and durability, provide invaluable advantages. These vessels help enhance fuel efficiency, reduce payload weight, and support safer storage of pressurized gases. Their robustness ensures they can withstand the intense conditions experienced during flight, from rapid acceleration to varying atmospheric pressures. As a result, Type 4 pressure vessels are a preferred choice in aerospace applications, where performance and safety are critical.

For chemical processing plants, Type 4 pressure vessels offer exceptional benefits, particularly due to their superior material composition that resists corrosion and chemical degradation. These vessels ensure the containment and safe storage of aggressive and reactive chemicals, making them ideal for environments where standard materials may fail. The robust construction of Type 4 vessels also reduces the need for frequent replacements or maintenance, making them a cost-effective solution for facilities dealing with hazardous substances.

In the natural gas industry, Type 4 pressure vessels play a pivotal role by providing secure and efficient storage and transportation solutions. Their lightweight nature allows for easier transportation logistics, and their strength ensures that they can withstand the high pressures associated with natural gas storage. Additionally, these vessels contribute to safer handling and reduced risk of leaks, enhancing overall safety in gas transport and storage operations. This reliability makes Type 4 vessels a top choice for natural gas companies seeking dependable and durable storage options.

Composite materials in Type 4 vessels offer enhanced durability, ensuring longevity and consistent performance.

These vessels resist environmental factors, from corrosion to external pressures, ensuring they remain operational for longer.

With a focus on sustainability, Type 4 vessels are designed to have a reduced environmental footprint, aligning with global green initiatives.

Businesses benefit from significant long-term savings, thanks to the vessel’s durability and reduced maintenance needs.

The efficiency and longevity of Type 4 vessels ensure a higher return on investment for businesses.

With lower maintenance requirements, operational costs are significantly reduced, ensuring cost-effectiveness.

Type 4 vessels adhere to stringent regulatory guidelines, ensuring they meet global safety standards.

Red River LLC champions best practices and safety protocols, ensuring every vessel is up to the mark.

Safety isn’t just a standard; it’s a commitment. At Red River LLC, every vessel embodies our unwavering dedication to safety and excellence.

While Type 1 vessels rely primarily on metal structures, Type 4 vessels utilize advanced composite materials, offering enhanced durability and weight reduction. This evolution in design translates to improved efficiency and safety in Type 4 vessels.

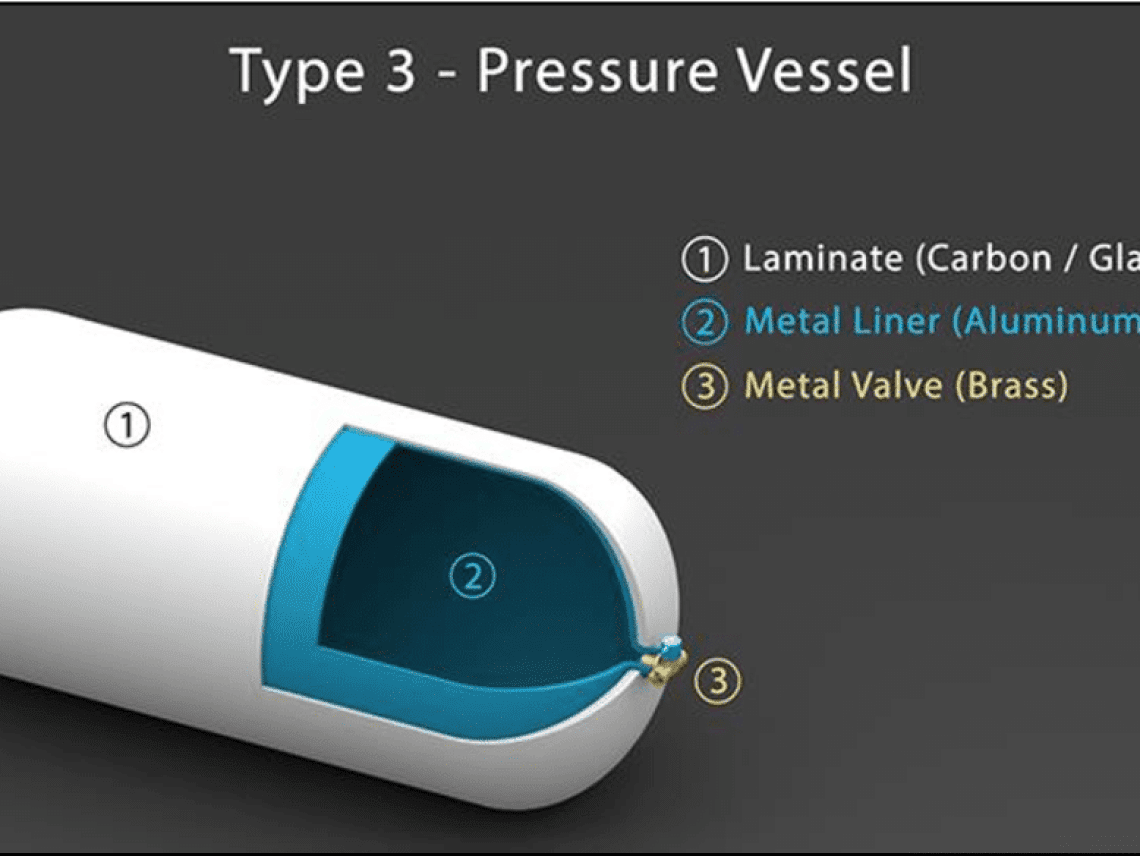

Transitioning from Type 2 and 3, Type 4 vessels have incorporated the best of both while introducing innovations. The result is a vessel that’s more resilient, lightweight, and adaptable to diverse applications.

The clear advantages of Type 4, from cost savings to enhanced safety, make it the preferred choice for forward-thinking businesses seeking optimal performance.

Our clients frequently report enhanced operational efficiency and safety with Type 4 vessels, underscoring their real-world benefits.

Consistent positive feedback highlights our commitment to quality and client satisfaction, reinforcing our position as industry leaders.

Detailed case studies reveal the tangible benefits of Type 4 vessels, from increased ROI to operational excellence.

Begin your journey with our expert consultation, ensuring you choose the right vessel for your needs.

Every business is unique. We offer tailored solutions, ensuring your specific requirements are met.

Ready to explore the benefits of Type 4 vessels? Reach out to Red River LLC and let’s embark on this journey together.

Type 4 pressure vessels find extensive use in industries like aerospace, aviation, natural gas storage, and transportation, chemical processing plants, and more. Their lightweight yet durable design makes them versatile for various applications, enhancing safety and efficiency.

Type 4 pressure vessels stand out with their composite material construction, offering enhanced safety, reduced weight, and superior durability when compared to traditional Type 1 vessels, which often rely on metals. This advanced technology ensures optimal performance and longevity.

Yes, Type 4 pressure vessels are considered environmentally friendly due to their reduced carbon footprint. The composite materials used in their construction make them a sustainable choice, aligning with global green initiatives and sustainability goals.

Type 4 pressure vessels offer long-term cost savings through reduced maintenance and operational costs. Their durability and lightweight design lead to lower transportation costs, making them a cost-effective choice for industries.

Red River LLC prioritizes safety and compliance by adhering to stringent quality control measures, full traceability of materials, and compliance with industry standards like ASME. Our commitment to continuous improvement ensures the highest quality and safety for every pressure vessel we manufacture.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.