Table of Contents

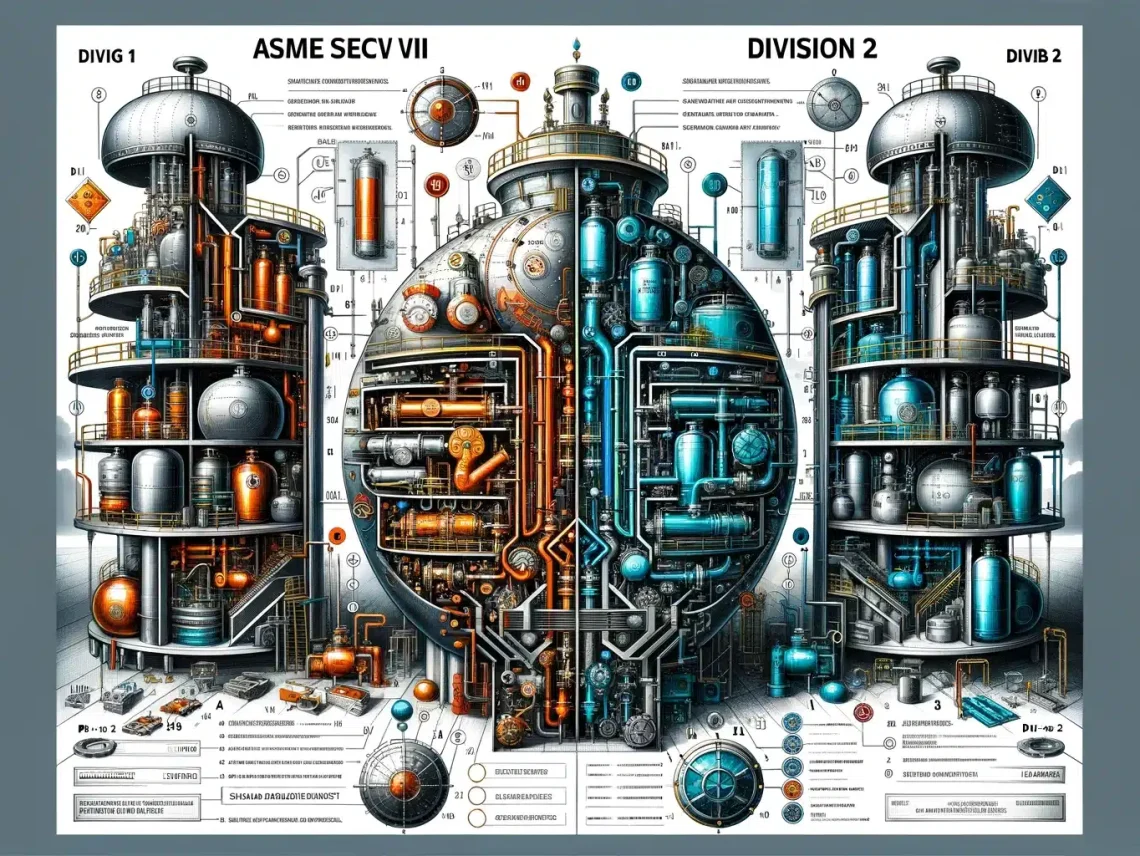

ToggleASME Section VIII Div 1 offers a conservative, rule-based approach ideal for standard pressure vessel designs, while Div 2 provides more flexibility with performance-based methodologies, enabling thinner materials and optimization for high-pressure, custom applications. Choosing between the two affects cost, manufacturing complexity, and long-term efficiency, with Div 2 being more suited for complex, high-pressure needs.

Designing and fabricating a pressure vessel under ASME BPVC Section VIII Division 1 is a detailed process that demands precision and engineering expertise. We’re also well-versed in ASME BPVC Section VIII Division 2, allowing us to support performance-based designs where innovation and optimization are critical.

Choosing between ASME Section VIII Division 1 and Division 2 impacts vessel safety, project costs, and long-term efficiency. Division 1 offers a conservative, rule-based approach, while Division 2 enables thinner, optimized designs via advanced stress analysis and material selections.

Within Section VIII, your choice of division affects material requirements, fabrication complexity, inspection protocols, and certification pathways. Division 1 is straightforward and widely used. Division 2 offers flexibility for high-pressure, custom-engineered applications.

Division 1 is a prescriptive standard detailing the design, fabrication, inspection, and testing of pressure vessels operating above 15 psig, emphasizing safety through conservative rules and conservative stress factors.

Materials must meet rigorous standards, and design requires thicker walls and higher safety margins to ensure reliability.

Division 1 builds in higher design factors, prioritizing robust and time-tested construction methods.

Division 2 introduces more advanced design-by-analysis techniques, including fatigue assessment and finite element analysis to optimize vessel designs

Division 2 enables designs with thinner, high-strength materials and includes rigorous stress and fatigue analysis methods tailored to high-pressure applications.

Division 2 sets higher standards for material strength, facilitating the use of thinner, lighter materials without compromising vessel integrity.

It encourages innovation, with a performance-based code that allows for the application of state-of-the-art design methodologies.

| Criteria | Division 1 | Division 2 |

|---|---|---|

| Design Methodology | Design‐by‐rule (prescriptive) | Design‐by‐analysis (performance‐based) |

| Applicable Pressures | Up to ~3,000 psi | Up to ~10,000 psi |

| Material Thickness | Thicker, standard-grade materials | Thinner, high-performance alloys |

| Cost Efficiency | Lower cost for standard applications | Cost-saving for bespoke, high-pressure systems |

| Manufacturing | Standard fabrication processes | Advanced analysis and fabrication methods |

| Quality Control | Standard inspection and testing | Enhanced NDE and detailed QA requirements |

Division 1 may be more cost-effective for standard applications, whereas Division 2 can be cost-saving for complex, high-pressure needs due to material efficiencies.

The manufacturing processes under each division vary, with Division 2 often involving more sophisticated fabrication techniques.

Both divisions maintain stringent quality assurance protocols, though Division 2’s are typically more comprehensive due to their custom nature.

The origins of ASME standards date back to safety concerns of the industrial age, aiming to prevent accidents and ensure public safety.

Division 1 has evolved over time, incorporating feedback from industry use and technological advancements.

The shift to Division 2 reflects the industry’s move towards more efficient and optimized design practices.

Both divisions employ stress analysis, but Division 2 allows for a more detailed and refined approach.

Design pressure and temperature are critical factors in both, but Division 2 offers more precise tools for assessment.

Fatigue assessment is integral to both divisions, ensuring vessels can withstand cyclic loads over their lifespan.

Choosing between ASME SEC 8 Div 1 and Div 2 can have significant implications for your business operations and bottom line. Div 1 may offer a cost-effective solution for standard pressure needs, while Div 2 can provide a customized approach for more demanding applications, potentially reducing long-term operational costs.

Understanding the nuances of ASME compliance is crucial. Red River LLC ensures your pressure vessels meet all certification requirements, providing peace of mind and a clear path to market.

Adhering to ASME standards minimizes risk, ensuring the safety and durability of pressure vessels. Red River LLC’s commitment to these standards protects your business and reputation.

Our portfolio showcases successful applications of Div 1 standards across various industries, demonstrating our expertise and the versatility of this division.

Red River LLC has pioneered projects utilizing Div 2 standards, pushing the boundaries of pressure vessel design and application.

We provide a detailed comparison of outcomes from Div 1 and Div 2 projects, highlighting the tailored benefits and efficiencies achieved.

Stay ahead of industry trends with Red River LLC as we navigate the future landscape of pressure vessel design together.

Technology plays a pivotal role in the evolution of ASME codes, and Red River LLC is at the forefront, integrating the latest advancements into our manufacturing processes.

Red River LLC is actively involved in shaping the future of ASME SEC 8, ensuring that our clients are always ahead of the curve.

With deep expertise in both divisions, Red River LLC is your trusted partner for pressure vessel manufacturing.

We offer bespoke design solutions that meet your unique requirements, ensuring optimal performance and compliance.

Our unwavering commitment to safety and quality underpins every project, aligning with the stringent standards of ASME SEC 8.

ASME SEC 8 Division 1 follows a prescriptive approach with specific guidelines for design, while Division 2 offers a more performance-based, flexible design approach. Div 1 is suitable for standard applications, while Div 2 caters to complex, high-pressure needs, often allowing for thinner materials, enhancing efficiency, and reducing long-term operational costs.

The choice between Div 1 and Div 2 can significantly impact project costs. Division 1 may be more cost-effective for standard applications due to its conservative design approach, while Division 2’s advanced materials and design methodologies can lead to cost savings in complex, high-pressure environments.

Certainly! Division 1 is often used for applications like standard industrial boilers and pressure vessels. In contrast, Division 2 is ideal for applications requiring customization, such as high-pressure systems in the oil and gas industry, where optimizing design is crucial.

ASME SEC 8 Div 1 and Div 2 have evolved in response to industry needs. Division 1 has incorporated feedback from industrial use and technological advancements, while Division 2 represents a shift toward more efficient and optimized design practices.

Both divisions employ stress analysis, but Division 2 allows for a more detailed and refined approach, considering factors like design pressure and temperature with greater precision. Division 2’s advanced analysis tools enable engineers to optimize designs for specific conditions.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.