Table of Contents

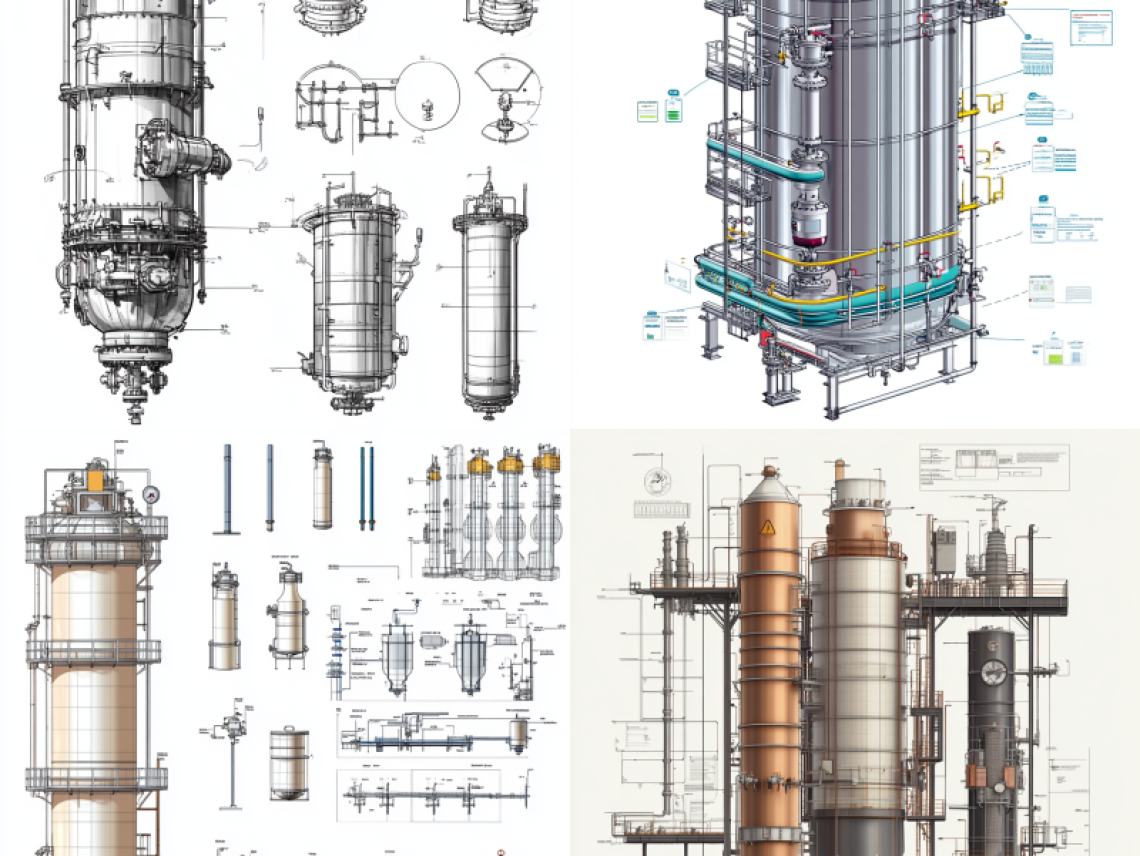

ToggleWhen evaluating equipment for your industrial process system, knowing the difference between a pressure vessel vs column can dramatically improve operational safety, performance, and cost-effectiveness. While they may appear similar at first glance, understanding the function and design of a pressure vessel vs column is essential for efficient system planning and engineering.

In the world of industrial manufacturing, especially in sectors like oil and gas, petrochemical, and power generation, both pressure vessels and columns are indispensable. However, when considering a pressure vessel vs column, it’s clear they serve very different purposes.

A pressure vessel is a closed container specifically designed to hold gases or liquids at a pressure substantially different from ambient pressure. In the debate of pressure vessel vs column, the pressure vessel’s main role is storage and containment under pressure.

Most pressure vessels are cylindrical and feature hemispherical or elliptical heads. Whether horizontal or vertical, their design helps evenly distribute stress caused by internal pressure.

Common materials used:

Designs must comply with the ASME Boiler and Pressure Vessel Code (BPVC), especially when comparing a pressure vessel vs column in terms of safety and pressure tolerance.

Key design features include:

Pressure relief valves and other safety mechanisms are critical for preventing dangerous failures.

In contrast to pressure vessels, a column (also known as a process column or tower) is used for separation rather than containment. When comparing a pressure vessel vs column, the column plays a more active role in processing fluids.

Columns are primarily used to separate fluid mixtures based on physical properties such as:

The internal structure of columns sets them apart in the pressure vessel vs column comparison. These include:

These elements enhance contact between vapor and liquid phases, allowing for efficient mass transfer and separation.

When evaluating pressure vessel vs column, material choice plays a big role in functionality and longevity. While both use materials like carbon or stainless steel, selection depends on:

In high-temperature or corrosive environments, unfamiliar alloys might be necessary for either vessel.

Understanding the difference between a pressure vessel vs column is vital for designing safe and effective process systems. While pressure vessels are designed for storing and containing pressurized substances, columns are engineered for separating mixtures through physical processes. Both serve critical but distinct roles in industries such as oil and gas, refining, and chemical processing.

Knowing when to use a pressure vessel vs column will improve your system’s performance, enhance safety, and help you stay compliant with industry standards.

Despite their visual similarities, pressure vessels and columns are built and used differently. Here’s how they compare:

Both can operate under high pressure and temperature, but columns often involve multi-phase flows, increasing complexity.

For further details on codes and standards, the ASME Boiler and Pressure Vessel Code offers a comprehensive breakdown of design requirements.

Whether you’re building a pressure vessel or a column, safety and material selection are paramount. Design engineers must consider:

Pressure vessels must meet ASME Section VIII Division 1 or 2 design codes, while columns may follow additional standards like API 650/620, depending on their use.

Additionally, Non-Destructive Examination (NDE) techniques such as:

They are employed to verify structural integrity.

Red River LLC follows stringent quality control processes for all pressure vessel fabrications. Visit our homepage to learn more about our standards and capabilities.

Knowing the difference between a pressure vessel and a column is crucial for anyone involved in process engineering, plant design, or industrial fabrication. Though they may appear similar externally, their core purposes, internal designs, and operational parameters vary greatly. Choosing the right unit depends on your process goals—whether you’re storing pressurized fluid or separating volatile compounds.

When you partner with a manufacturer that understands these distinctions and follows rigorous engineering standards, you’re not just buying equipment—you’re ensuring reliability, safety, and performance.

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

To contain gases or liquids at pressures significantly higher or lower than atmospheric pressure, ensuring safe storage or reaction conditions.

Columns separate different components of a chemical mixture based on boiling points, molecular weight, or solubility, often through distillation or absorption.

Yes, technically. Many columns operate under pressure and must comply with pressure vessel codes, but their primary function is separation.

Common choices include carbon steel, stainless steel, and nickel alloys, selected based on pressure ratings, corrosion, and chemical compatibility.

Using methods like hydrotesting, ultrasonic testing, and X-rays, following ASME and API code requirements.

Yes, columns are typically tall vertical structures designed for gravity-based phase separation, while pressure vessels can be horizontal or vertical.

Generally, yes. Columns are more complex due to their height, internal structures, and the engineering required for separation efficiency.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.