Tank Vessel vs Pressure Vessel: Key Differences and Uses

Tank Vessel vs Pressure Vessel: Key Differences and Applications

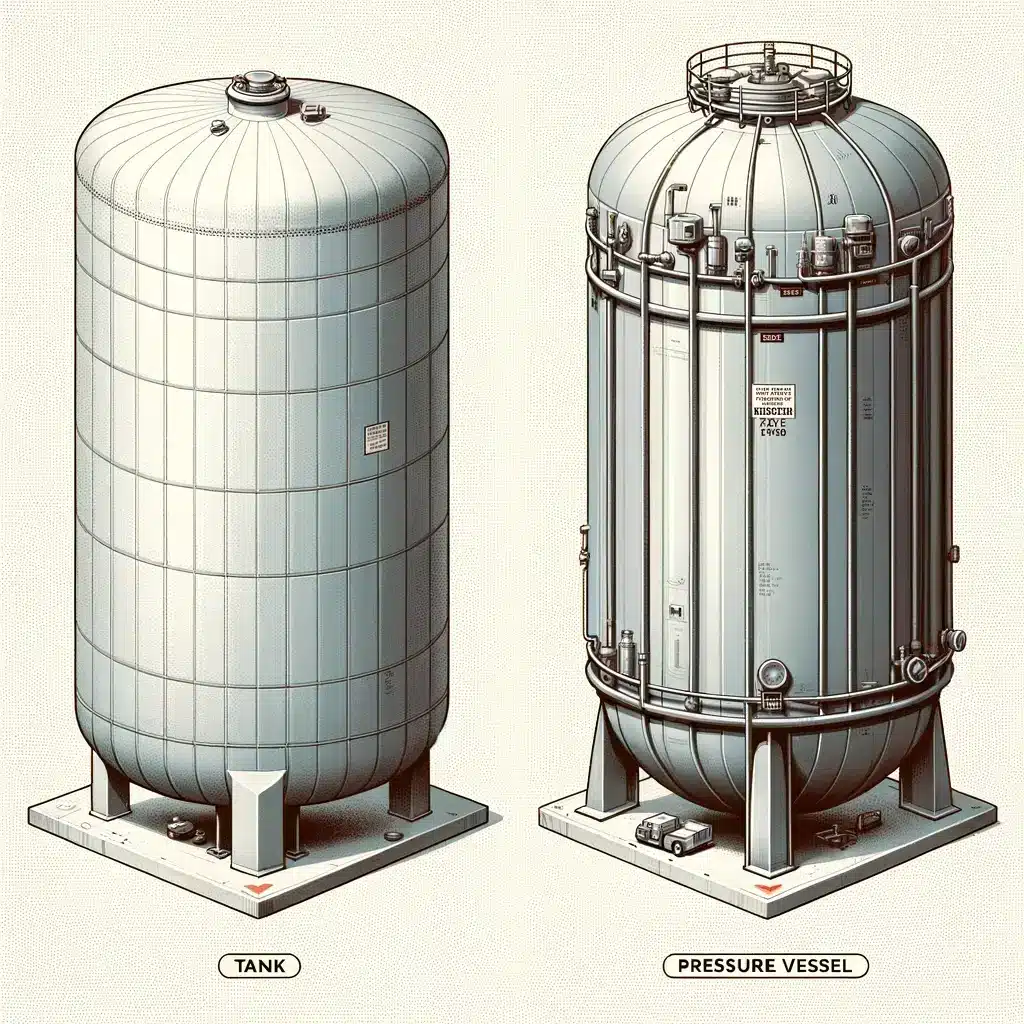

In industrial equipment, shipping, and engineering, the terms “tank,” “pressure vessel,” and “tank vessel” are often used interchangeably. However, they refer to different things. A tank vessel in marine industries is a ship designed to transport bulk liquids like oil, chemicals, or liquefied gases, while in engineering, tanks and pressure vessels are stationary equipment built for storage and containment. These distinctions matter because each follows unique functions, regulations, and design standards. This article highlights the key differences between tanks, pressure vessels, and tank vessels, focusing on their functions, designs, and applications.

Purpose and Function

Tanks: Tanks primarily store liquids or gases at atmospheric or minimal pressure. They hold substances without requiring specific pressure maintenance. Tanks accommodate a variety of materials, such as water, oil, chemicals, and even dry bulk items like grain.

Pressure Vessels: Pressure vessels store, process, or transport materials under high internal or external pressure. Industries like petrochemical, pharmaceutical, and power generation rely on these vessels to handle materials like compressed air, steam, or specific chemicals.

Pressure Handling

Tanks: Tanks handle the weight of stored materials and the internal forces they generate. However, they lack features like pressure relief valves and are unsuitable for maintaining specific pressure levels.

Pressure Vessels: Engineers equip pressure vessels with safety features, including relief valves, rupture disks, and pressure gauges. These additions help maintain safe pressure levels and prevent failures.

Design Considerations

Tanks: Tanks feature simpler designs, typically cylindrical or rectangular, with minimal structural reinforcement. Engineers focus primarily on storage as the main purpose of these designs.

Pressure Vessels: Pressure vessels include complex designs to handle factors like material strength, stress distribution, and pressure containment. Their shapes, often spherical or cylindrical, ensure even stress distribution. Rigorous testing and inspections validate their compliance with safety standards.

Regulatory Compliance

Tanks: Regulatory guidelines for tanks primarily address storage, spill prevention, and environmental safety. These regulations are generally less stringent compared to those applied to pressure vessels.

Pressure Vessels: Pressure vessels follow strict standards like ASME-certified vessels (American Society of Mechanical Engineers) codes and PED (Pressure Equipment Directive) in Europe. These regulations cover design, fabrication, inspection, and operation to minimize accident risks.

Materials Used

Tanks: Tanks use materials such as mild steel, stainless steel, or plastic, depending on the stored material. Cost, corrosion resistance, and the nature of the contents guide material selection.

Pressure Vessels: Manufacturers typically choose high-strength materials like carbon steel, stainless steel, or specialized alloys for pressure vessels. These materials withstand the significant stresses and pressures encountered during operation.

Examples of Applications

Tanks: Tanks serve various industries, including agriculture, water treatment, food processing, and residential use. Common examples include water storage tanks, fuel tanks, and grain silos.

Pressure Vessels: Industries like chemical, energy production, and manufacturing, rely on pressure vessels. Aerospace applications, including spacecraft propulsion systems, also use pressure vessels.

What is a Tank Vessel?

The term “tank vessel” can mean different things depending on context:

Marine Definition: In shipping, a tank vessel is a ship designed to transport liquid cargo such as crude oil, petroleum products, chemicals, or liquefied natural gas. These vessels are highly regulated by organizations like the International Maritime Organization (IMO) and the U.S. Coast Guard to ensure safety and environmental protection.

Industrial Definition: In engineering, some professionals use “tank vessel” to loosely refer to storage tanks or pressure vessels that hold liquids or gases. However, the correct technical term in this context is usually just “tank” or “pressure vessel.”

Understanding this distinction prevents confusion and ensures you apply the right regulations and standards for your industry.

Maintenance and Inspection

Tanks: Maintaining tanks often involves cleaning, preventing corrosion, and detecting leaks. While tanks need upkeep, their maintenance demands are less frequent and less complex compared to pressure vessels.

Pressure Vessels: Pressure vessels undergo rigorous maintenance to ensure safety. Inspections, non-destructive testing (NDT), and pressure tests help identify wear, corrosion, or structural issues that could compromise their integrity.

Cost Considerations

Tanks: Tanks provide a cost-effective solution for storage needs where pressure is not a concern. Their simpler designs and lower manufacturing requirements make them affordable to produce and maintain.

Pressure Vessels: Pressure vessels incur higher costs due to their intricate designs, specialized materials, and strict manufacturing standards. Additional expenses arise from pressure relief systems and frequent inspections, increasing operational costs.

Transport and Mobility

- Tanks: Tanks are often used for stationary storage applications, where mobility is not a primary concern. They can be located above ground, underground, or in fixed positions within facilities.

- Pressure Vessels: Pressure vessels, particularly in industries like aerospace, may be designed for mobility and transport. They are engineered to withstand dynamic forces associated with transportation, making them suitable for applications where materials need to be transported under pressure.

Environmental Impact

- Tanks: Tanks typically have a lower environmental impact when used for storing non-hazardous materials. However, improper maintenance or leaks can result in environmental pollution.

- Pressure Vessels: Pressure vessels, especially those used in chemical or petrochemical industries, may pose a higher environmental risk if they fail. Strict regulations and safety measures are in place to minimize the potential environmental impact of pressure vessel failures.

Safety Regulations and Codes

- Tanks: Tanks are subject to safety regulations primarily related to environmental protection, fire prevention, and structural integrity. These regulations vary depending on the contents of the tank and its location but are generally less stringent than those for pressure vessels.

- Pressure Vessels: Pressure vessels are subject to comprehensive safety regulations and codes, often enforced by organizations like the American Society of Mechanical Engineers (ASME) in the United States. These codes specify stringent design, fabrication, inspection, and testing requirements to ensure the highest level of safety for pressure vessel operation.

Customization and Complexity

- Tanks: Tanks are relatively straightforward in design and can be easily customized to meet specific storage needs. They are available in various sizes, shapes, and materials to accommodate different requirements.

- Pressure Vessels: Pressure vessels are typically more complex due to their intricate design and the need to withstand high pressures. Customizing pressure vessels often requires specialized engineering and manufacturing processes to meet the unique demands of specific applications.

Longevity

- Tanks: Tanks, when properly maintained, can have a long service life. Their longevity is primarily determined by factors such as corrosion resistance and the quality of materials used in construction.

- Pressure Vessels: Pressure vessels are designed with a focus on durability and longevity, given their critical role in high-pressure applications. They are built to withstand the stresses associated with pressure cycling, ensuring a long operational life.

Maintenance and Repairs

- Tanks: Maintenance for tanks typically involves routine inspections for corrosion, leakage, and structural integrity. Repairs may include patching or replacing damaged sections.

- Pressure Vessels: Pressure vessel maintenance is more rigorous and requires adherence to strict inspection schedules, non-destructive testing, and pressure testing. Repairs must be carried out with precision to ensure safety and compliance with regulatory standards.

Use of Tanks and Pressure Vessels in Combination

In some industrial applications, tanks and pressure vessels are used in combination to optimize processes and safety. This approach leverages the strengths of each component to meet specific operational requirements. Here’s how they can work together:

- Tanks in Conjunction with Pressure Vessels: In scenarios where a process requires both storage and controlled pressure conditions, tanks are often used as storage reservoirs connected to pressure vessels. For instance, a chemical processing plant might use a tank to store raw materials and then transfer them to a pressure vessel for chemical reactions that require precise pressure and temperature control.

- Safety Considerations: When tanks and pressure vessels are integrated into a system, safety measures become more complex but essential. Properly designed connections, relief systems, and interlocks ensure that materials can be safely transferred between the tank and the pressure vessel, minimizing the risk of accidents.

Emerging Technologies and Innovations

As technology evolves, so do the designs and applications of tanks and pressure vessels. Emerging innovations in materials, manufacturing techniques, and safety systems continue to enhance the performance and capabilities of these equipment types. This includes the development of advanced composite materials for lightweight, high-strength pressure vessels and the use of smart sensors and monitoring systems for real-time performance assessment.

Environmental Considerations

In recent years, there has been a growing focus on environmental sustainability and reducing the carbon footprint of industrial processes. This shift in perspective has influenced the design and usage of both tanks and pressure vessels.

- Tanks: Tanks used for storing hazardous materials or liquids that can potentially harm the environment are subject to stricter regulations. The focus has shifted towards designing tanks that are more environmentally friendly, with features such as double-walled tanks to prevent leaks and advanced corrosion-resistant coatings to reduce the risk of environmental contamination.

- Pressure Vessels: The environmental impact of pressure vessels is also a concern, especially in industries with high energy consumption. Innovations in pressure vessel design aim to improve energy efficiency, reduce greenhouse gas emissions, and minimize waste. For example, in the power generation sector, advancements in pressure vessel technology contribute to more efficient energy production with lower environmental impact.

Digitalization and Automation

The integration of digitalization and automation technologies has transformed the way tanks and pressure vessels are monitored and controlled in industrial processes.

- Tanks: Smart sensors and IoT (Internet of Things) technology are increasingly used to monitor the level, temperature, and pressure inside tanks. This data is then used to optimize storage conditions, prevent overflows, and reduce energy consumption in tank-related operations.

- Pressure Vessels: Pressure vessels benefit from real-time monitoring systems that can detect anomalies and deviations in pressure and temperature. Automation can control the pressure vessel’s operation precisely, ensuring it operates within safe parameters and maximizing efficiency.

Industry-Specific Advancements

Different industries continue to drive innovations in both tanks and pressure vessels. For example:

- Oil and Gas Industry: The demand for larger, more robust pressure vessels capable of handling extreme conditions has led to advancements in materials and manufacturing processes, enabling the extraction and transportation of oil and gas resources from remote locations.

- Pharmaceutical Industry: Pressure vessels used in pharmaceutical manufacturing are designed to meet strict hygiene and safety standards, with features such as polished surfaces, sterile connections, and advanced control systems to maintain precise pressure and temperature conditions.

Future Prospects

The future of tanks and pressure vessels will likely involve further integration of sustainable materials, advanced monitoring technologies, and improved safety features. As industries evolve and environmental concerns continue to grow, the development of equipment that meets both operational and sustainability goals will be a priority.

Training and Certification

As the importance of safety and compliance continues to rise, specialized training and certification programs for professionals working with tanks and pressure vessels are becoming more prevalent. These programs aim to ensure that engineers, inspectors, and operators possess the necessary knowledge and skills to handle these critical pieces of equipment.

- Certified Pressure Vessel Inspectors: Organizations like the American Society of Mechanical Engineers (ASME) offer certification programs for individuals responsible for inspecting and maintaining pressure vessels. These certifications demonstrate expertise in adhering to industry standards and ensuring the safety of pressure vessel operations.

- Tank Maintenance and Safety Training: Similar programs exist for professionals dealing with tanks, particularly those used for hazardous materials. Proper training helps individuals understand environmental regulations, safety protocols, and best practices for tank maintenance.

Global Harmonization of Standards

In an increasingly interconnected world, efforts are being made to harmonize standards and regulations related to tanks and pressure vessels on a global scale. This harmonization helps streamline international trade, ensures consistent safety practices, and simplifies compliance for manufacturers and operators.

- International Codes and Standards: Organizations like the International Organization for Standardization (ISO) work on developing international standards that align with recognized codes like ASME and European Pressure Equipment Directive (PED). This global alignment simplifies the process of designing, manufacturing, and operating tanks and pressure vessels across borders.

Sustainability and Circular Economy

The concepts of sustainability and the circular economy are influencing the design and use of tanks and pressure vessels. Industries are exploring ways to extend the life cycle of these assets, reduce waste, and repurpose materials.

- Tank Repurposing: Decommissioned tanks can often be repurposed for other uses, such as rainwater harvesting, aquaculture, or even as building structures. This approach promotes sustainability and reduces the environmental impact of equipment disposal.

- Pressure Vessel Recycling: Recycling materials from pressure vessels at the end of their life cycle is becoming more common. High-quality steel and other materials can be extracted and reused, contributing to resource conservation.

Innovations in Materials

Advancements in materials science are leading to the development of new materials with enhanced properties for both tanks and pressure vessels.

- Composite Pressure Vessels: Lightweight composite materials, including carbon-fiber-reinforced composites, are being explored for pressure vessel applications, particularly in aerospace and transportation, to reduce weight and improve fuel efficiency.

- Corrosion-Resistant Coatings: Continuous development of advanced coatings and linings is extending the lifespan of tanks and pressure vessels by protecting them from corrosion, even in aggressive environments.

Integration with Renewable Energy

In the context of renewable energy production, tanks and pressure vessels play a vital role in energy storage systems. They are integral components in technologies such as compressed air energy storage, hydrogen storage, and thermal energy storage, which help store and release renewable energy efficiently.

Final Thoughts on Tanks, Pressure Vessels, and Tank Vessels

Understanding the difference between a tank, a pressure vessel, and a tank vessel is critical for choosing the right equipment and following industry standards.

- A tank is mainly for storage at atmospheric or minimal pressure.

- A pressure vessel is engineered to safely handle fluids under high pressure.

- A tank vessel in the marine industry is a ship designed to transport bulk liquids like oil, chemicals, or liquefied gases.

While the terms are sometimes used interchangeably, recognizing their distinctions ensures compliance with safety regulations, proper design, and more efficient operations in both industrial and maritime contexts.

Need a trusted partner for tanks and pressure vessels?

Red River specializes in the design and manufacturing of pressure vessels, prefabricated spools, and skid packages. Whether you’re working in oil & gas, power generation, or manufacturing, our American-made solutions are built for safety, compliance, and long-term reliability.

Reach out to us today and discover how Red River can support your next project.

FAQ: Understanding the Differences Between Tanks and Pressure Vessels

Is a tank vessel the same as a pressure vessel?

Not exactly. A tank vessel in marine terms is a ship designed to transport liquid cargo. A pressure vessel is an industrial container designed to store or process fluids under pressure. While they both carry liquids or gases, their applications, regulations, and designs are very different.

What distinguishes a tank from a pressure vessel in terms of design and construction?

Tanks and pressure vessels differ significantly in design and construction. A tank is typically designed for storage and is not meant to withstand internal pressure, thus it has a simpler, often cylindrical or rectangular shape. In contrast, a pressure vessel is engineered to hold fluids at a pressure substantially different from the ambient pressure. Therefore, they are constructed with stronger materials like stainless steel and have features like reinforced walls and safety valves to manage the high pressure.

Can pressure vessels be used for the same applications as tanks?

While there is some overlap in applications, pressure vessels and tanks serve different primary functions. Tanks are mainly used for storing liquids and gases under normal atmospheric pressure, such as water tanks or fuel storage tanks. Pressure vessels, however, are designed for specialized applications that involve holding gases or liquids at high pressures, like in the case of autoclaves, reactors, or gas storage cylinders. The choice between a tank and a pressure vessel depends on the pressure requirements of the stored substance.

Are the safety and regulatory requirements the same for tanks and pressure vessels?

No, the safety and regulatory requirements for tanks and pressure vessels are quite different due to their distinct operational conditions. Pressure vessels are subject to more stringent regulations and standards because they operate under high pressure, which poses a greater risk of accidents. They must comply with codes like the ASME Boiler and Pressure Vessel Code in the U.S. Tanks, being used in less hazardous conditions, have less rigorous compliance requirements.

How does the maintenance and inspection differ between tanks and pressure vessels?

Maintenance and inspection protocols differ significantly between tanks and pressure vessels due to their different uses and risks. Pressure vessels require more frequent and detailed inspections to ensure integrity under high-pressure conditions. These inspections often involve checking for cracks, corrosion, and material fatigue. Tanks, while also needing regular maintenance, generally have simpler inspection routines focused on leak prevention and structural integrity.

What are the material considerations when choosing between a tank and a pressure vessel for a specific application?

Material selection is crucial and varies between tanks and pressure vessels. For tanks, materials like plastic, fiberglass, or mild steel are often sufficient, considering they mostly hold substances at atmospheric pressure. Pressure vessels, on the other hand, require materials that can withstand high pressure and potential chemical reactions. This often leads to the choice of stronger metals like stainless steel or alloys designed for specific chemical resistances and strength characteristics.

Key Takeaways

- Tank: Stores liquids or gases at low/atmospheric pressure.

- Pressure Vessel: Contains fluids under high pressure with strict safety standards (ASME, PED).

- Tank Vessel: Ship used for transporting bulk liquids (oil, chemicals, LNG).

- Main Difference: Tanks = storage, Pressure Vessels = high-pressure containment, Tank Vessels = marine transport.

- Why It Matters: Correct classification avoids safety risks, ensures compliance, and matches industry best practices.

Related Blog Post

- How do pressure vessels fail?

- Why do pressure vessels explode?

- What material are vessels made of?

- How do you weld a pressure vessel?

- How thick are pressure vessel walls?

- What is a pressure vessel also known as?

- What are the disadvantages of pressure vessels?

- What is the most common pressure vessel material?

- What is the difference between a tank and a pressure vessel?

- Which of the following are a type of a pressure vessel?

- What is the definition of simple pressure vessel?

- Is an air compressor a pressure vessel?

- What does a pressure vessel consist of?

- What is an external pressure vessel?

- What is an example of an unfired pressure vessel?

- What is a steel pressure vessel?

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.

Related Blog Post

How a Glycol System Works

Ethylene Glycol Water: A Complete Heat Transfer Guide

Water Filter Replacement

Why Use Stainless Steel Sheet Metal Fabrication?

How Does Stainless Steel Sheet Metal Fabrication Work

No pillar keyword set for this post.

About Author