Maximizing the efficiency of a 2-phase separator is crucial in industries such as oil and gas, power generation, and biogas production. By optimizing design, maintaining components, and leveraging advanced technologies, you can improve operational performance, reduce costs, and enhance product recovery.

Maximizing the Efficiency of a 2-Phase Separator: Key Considerations and Best Practices

At Red River, we understand that the efficiency of a 2-phase separator is critical for optimizing your operations. Whether you’re in the oil and gas industry, power generation, or biogas production, a well-functioning 2-phase separator plays a key role in ensuring operational effectiveness. In this article, we’ll explore the factors that affect separator efficiency, best practices for optimization, and the technologies that can help improve performance.

Overview of the 2-Phase Separation Process

A 2-phase separator is an essential device used to separate different phases typically liquid and gas from a mixture. The separator works by capitalizing on the density differences between the two phases, with the gas rising to the top and the liquid settling at the bottom. By optimizing this natural separation process, you can improve efficiency, reduce energy consumption, and maximize product recovery.

Understanding the efficiency of your separator is key. Efficient separation not only enhances product recovery but also minimizes energy and resource consumption, making your operation more effective and cost-efficient.

Key Components of a 2-Phase Separator

To maximize the efficiency of a 2-phase separator, it’s essential to understand the key components that contribute to optimal performance:

- Inlet and Outlet Nozzles: These are the entry and exit points where the mixture enters and the separated phases exit.

- Vortex Breaker: Prevents fluid swirling, ensuring smooth and efficient separation.

- Mist Extractor: Removes liquid droplets from the gas phase, ensuring high purity of the gas.

- Weirs and Baffles: These guide the phases and assist in proper settling and distribution within the separator.

By optimizing these components, you can significantly improve the separation process, making it faster, cleaner, and more efficient.

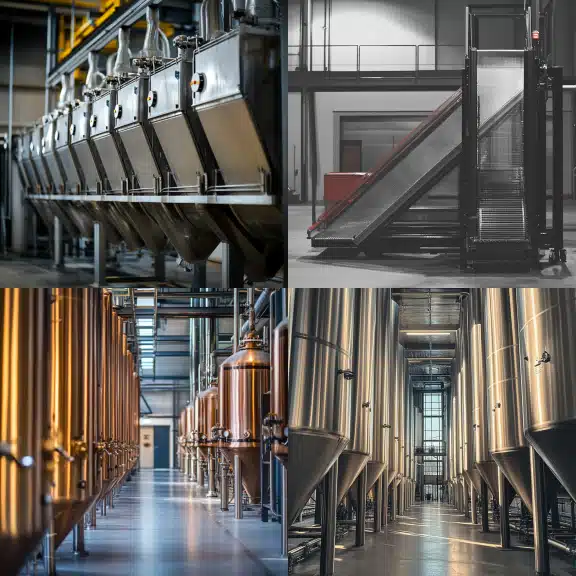

Applications of Two-Phase Separators in Industry

Two-phase separators are employed across various industries, where they play a vital role in improving operational efficiency and safety. In the oil and gas sector, for instance, they are used to separate crude oil from natural gas, ensuring that each product is ready for further processing. In power generation, they help in separating steam from water, improving the efficiency of turbines and reducing wear and tear.

Factors Affecting the Efficiency of a 2-Phase Separator

Fluid Properties

The properties of the fluids being separated density, viscosity, and temperature play a critical role in the efficiency of the separation process. For instance, fluids with higher viscosity tend to separate more slowly, which can affect the efficiency of separation. Temperature fluctuations can also impact fluid viscosity, making the separation process less predictable.

Carefully considering these properties during the design and operation of the separator can enhance its efficiency and reliability.

Design Considerations

The design of the separator plays a crucial role in its performance. Proper sizing, well-placed baffles, and mist extractors, as well as optimizing inlet and outlet placements, can all contribute to maximum efficiency. A well-designed separator ensures that fluids are evenly distributed, allowing for faster and cleaner separation, which in turn reduces downtime and increases throughput.

How to Improve the Efficiency of a 2-Phase Separator

To optimize the performance of your 2-phase separator, follow these best practices:

- Proper Sizing: Ensure that the separator is sized correctly for the fluid properties and flow rates in your operation.

- Regular Maintenance: Scheduled inspections, cleaning, and component replacements help prevent issues such as blockages, corrosion, and leaks. This will help maintain the separator’s efficiency over time.

- Maintain Consistent Flow Rates: Avoid sudden surges in flow rates, as these can disrupt the separation process. A consistent flow rate ensures stable operation and better separation.

- Leverage Advanced Technologies: Incorporate innovations such as improved mist extractors, vortex breakers, and automated control systems for more precise and effective separation.

Measuring the Efficiency of a 2-Phase Separator

Monitoring the performance of your separator is essential to ensure it’s operating efficiently. Key metrics include:

- Separation Efficiency: Measures the effectiveness of the separator in distinguishing between the two phases typically gas and liquid.

- Pressure Drop: Indicates how much energy is lost in the process, with lower pressure drops generally indicating better efficiency.

- Flow Rates: These should align with the design parameters to ensure consistent performance.

- Purity of Separated Phases: Higher purity levels indicate better separation performance.

To gather this data, use tools such as flow meters, pressure gauges, and online monitoring systems. Advanced techniques like computational fluid dynamics (CFD) modeling can also help optimize separator design by providing insights into internal flow patterns.

Why Efficiency Matters: Economic and Environmental Impact

Cost Savings from Improved Efficiency

One of the most immediate benefits of a high-efficiency 2-phase separator is cost savings. Efficient separators reduce the energy required for separation, leading to lower operational costs. Additionally, improved efficiency minimizes product losses and maximizes recovery, ensuring that more valuable resources are captured and utilized. Over time, these savings can add up, making your operation more profitable and competitive.

Environmental Benefits of High-Efficiency Separators

High-efficiency separators offer significant environmental benefits as well. By reducing the energy required for operation, these separators help lower greenhouse gas emissions and decrease the overall environmental footprint of your facility. Additionally, efficient separation processes reduce waste and minimize the risk of environmental contamination, aligning your operation with sustainability goals and regulatory requirements.

Looking to Maximize the Efficiency of Your 2-Phase Separator?

Contact Red River for expert solutions in separator design, maintenance, and optimization. Our experience can help ensure that your 2-phase separator performs at its best, maximizing both economic and environmental benefits.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions

What Are the Usual Reasons for Inefficiency in a 2-Phase Separator?

Inefficiencies in a 2-phase separator can arise from several factors, such as improper sizing, inadequate maintenance, and fluid properties that don’t match the separator’s design. For instance, if the separator is too small for the fluid volume being processed, it may lead to poor separation and higher pressure drops. Regular maintenance, along with proper design considerations, is essential to address these challenges and maintain optimal performance.

How Can Fluid Properties Like Viscosity and Temperature Affect the Performance of a 2-Phase Separator?

Fluid properties like viscosity and temperature play a crucial role in the separation process. For example, higher viscosity fluids tend to separate more slowly, which can reduce efficiency. Temperature fluctuations can also affect viscosity, making the separation process unpredictable. By considering these properties during the design phase and monitoring them during operation, you can optimize separator performance.

Are There Specific Industries Where 2-Phase Separators Are Particularly Crucial?

Yes, 2-phase separators are particularly critical in industries such as oil and gas, power generation, and biogas production. In the oil and gas industry, they separate crude oil from natural gas, ensuring that each component is processed efficiently. In power generation, they separate steam from water to maintain turbine efficiency. In biogas production, they separate methane gas from liquid slurry, which is essential for producing clean energy. Each of these industries relies on high-efficiency separators to ensure productivity and safety.

What Advanced Technologies Are Available to Enhance the Efficiency of 2-Phase Separators?

Several advanced technologies can enhance the efficiency of 2-phase separators. For example:

- Enhanced mist extractors remove even the smallest droplets of liquid from the gas phase.

- Vortex breakers prevent swirling in the separator, leading to more stable and efficient separation.

- Automated control systems allow for real-time monitoring and adjustments, ensuring the separator operates at peak efficiency.

Incorporating these technologies can significantly improve the performance and reliability of your separator.

How Do You Measure the Efficiency of a 2-Phase Separator in a Real-World Setting?

To measure the efficiency of a 2-phase separator in real-world conditions, monitor several key metrics:

- Separation efficiency measures how effectively the separator distinguishes between liquid and gas.

- Pressure drop indicates how much energy is lost in the process; lower pressure drops generally suggest higher efficiency.

- Flow rates should be consistent with design parameters for optimal separation.

- Purity of separated phases: Higher purity indicates better performance.

Tools like flow meters, pressure gauges, and online monitoring systems provide real-time performance data, offering a clear picture of separator efficiency.

Key Takeaways:

- Proper design and maintenance are essential for optimizing separator efficiency.

- Fluid properties such as viscosity and temperature significantly impact the separation process.

- Advanced technologies like mist extractors and vortex breakers improve separator efficiency.

- Regular performance monitoring ensures that separators operate at peak efficiency.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author