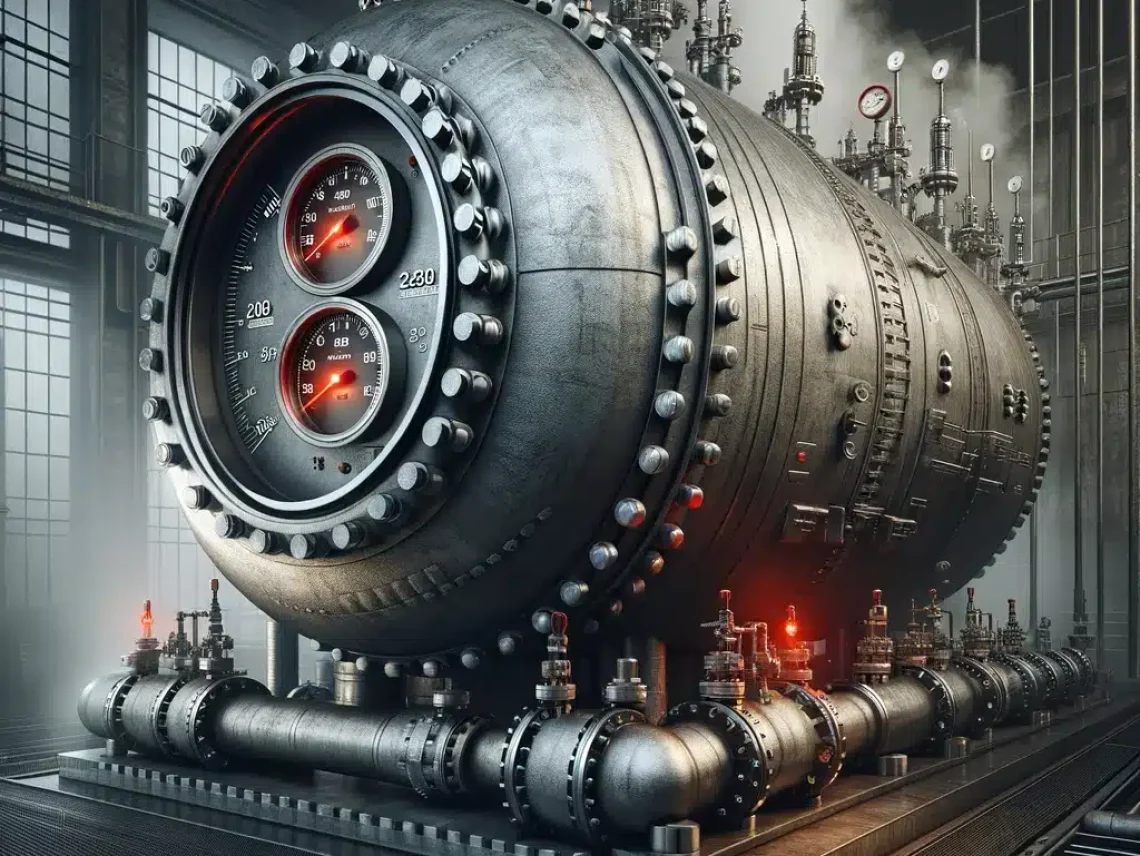

Safety isn’t just a buzzword for us; it’s a commitment woven into the fabric of our operations. In the industries we serve—ranging from oil and gasoline to biogas and energy generation—the stakes are undeniably high. Consequently, we don’t just adhere to basic safety protocols; we champion them. Moreover, our approach goes beyond meeting fundamental requirements. We continuously innovate and enhance protective measures, ensuring every pressure vessel we produce sets a benchmark for safety and reliability.

What defines a secure pressure vessel design? This question encompasses a range of factors, each as crucial as the next. For instance, selecting the right materials and ensuring structural integrity are foundational steps. Additionally, adhering to critical safety requirements for pressure vessel construction demands meticulous scrutiny of each component. As a result, our design standards are deeply rooted in engineering expertise and aimed at creating dependable pressure vessel layouts. This comprehensive approach ensures that each vessel we manufacture not only meets but often exceeds industry benchmarks.

At Red River, our dedication to safety is evident in every project we undertake. Our team, trained in advanced welding techniques and well-versed in best practices for pressure vessel protection, strives to deliver products that provide peace of mind. Furthermore, we recognize that our customers trust us with more than just their projects—they trust us with their safety and success. For this reason, we are driven to uphold the highest standards in every aspect of our work, from initial design to final transport.

We prioritize materials that are strong, corrosion-resistant, and capable of withstanding excessive pressures and temperatures. Therefore, our vessels are guaranteed to perform optimally in a variety of industrial applications.

The quality of materials directly affects a vessel’s integrity. For this reason, we utilize high-grade substances that ensure durability and reliability, significantly reducing the risk of failure while enhancing operational safety.

By incorporating superior materials and advanced technologies, we maintain our position at the forefront of pressure vessel fabrication. Consequently, our methods allow us to design vessels that are not only safe but also environmentally sustainable.

To ensure maximum safety, we precisely calculate wall thickness to withstand internal pressures. As a result, our vessels provide optimal performance without compromising structural integrity.

Our designs achieve the perfect balance between weight and strength. Consequently, this approach ensures that our vessels are both durable and efficient for a wide range of applications.

We design with longevity in mind, ensuring that our vessels are not only long-lasting but also easy to maintain. Furthermore, this extends the lifespan of our products while reducing overall operational costs.

We meticulously examine pressure limits and tolerances to ensure every vessel is equipped to handle its intended use effectively. As a result, our designs offer reliability under diverse conditions.

Pressure ratings significantly guide our design decisions. Therefore, we ensure each vessel operates safely within the specified conditions, minimizing potential risks.

We customize pressure ratings based on specific applications, thereby providing tailored solutions that meet our customers’ exact needs.

Our skilled technicians employ advanced strategies to create leak-proof joints, which are a critical component of pressure vessel safety. Consequently, these techniques enhance the overall reliability of our products.

We stay at the forefront of welding technology advancements. By doing so, we continuously improve the safety and durability of our vessels.

Our rigorous quality control measures ensure that every weld meets the highest standards of protection and durability. Furthermore, this approach guarantees long-term performance.

We lay our vessels to include robust safety valves and comfort systems, making sure they can take care of overpressure events adequately.

We make use of diverse styles of safety valves, each particularly selected for its characteristics and suitability for the vessel’s utility.

Regular trying out and maintenance of those structures are quintessential to our dedication to protection, ensuring they feature correctly whilst wished.

We meticulously adhere to ASME codes and regulations, ensuring our vessels are compliant with the highest enterprise standards. This adherence isn’t pretty much meeting requirements; it is about making sure the utmost protection and reliability of our products.

Understanding the nuances among global standards and nearby rules is fundamental to our global compliance strategy. We navigate these complexities to supply merchandise that might be universally recognized for their protection and great.

Our approach to global compliance involves a proactive and knowledgeable engagement with worldwide standards, making sure our products are universally common and preferred.

Computer-aided engineering plays a pivotal role in our layout procedure, bearing in mind specific simulations and optimizations that enhance the protection and performance of our vessels.

Through rigorous pressure analysis and fatigue checking out, we make sure our vessels can resist the needs of their operational environments, guaranteeing durability and protection.

We conduct large real-world checking-out scenarios to validate our designs, ensuring they are carried out accurately and efficiently under actual running situations.

We tailor our designs to satisfy precise industry necessities, making sure each vessel we produce is ideally fitted to its intended application.

Our portfolio of revolutionary designs showcases our capacity to fulfill complex and unique demanding situations, demonstrating our understanding and dedication to custom answers.

We trust in close consultation and collaboration with our clients to apprehend their unique wishes, ensuring the final product is precisely what they require.

We stay abreast of rising trends in the pressure vessel era, making sure our services and products continue to be at the vanguard of the industry.

Sustainability is increasingly turning into a key attention in our vessel designs, as we try to create merchandise that isn’t most effectively secure but additionally environmentally accountable.

Our vision for destiny consists of non-stop innovation in safety, ensuring that we remain leaders in the pressure vessel production industry.

The design of a pressure vessel needs to prioritize fabric selection, pressure ratings, wall thickness, and the vessel’s common geometry. Material preference is essential for ensuring durability and resistance to corrosion and temperature. Pressure scores decide the most pressure the vessel can competently cope with, whilst wall thickness is calculated based totally on the vessel’s length, pressure, and cloth power. The geometry, inclusive of shape and size, affects the vessel’s capability to resist internal pressures and outside forces.

Environmental elements play a big function in pressure vessel layout. Conditions which include severe temperatures, corrosive environments, and seismic pastime require specific layout considerations. For example, vessels utilized in offshore settings must be designed to face up to corrosive saltwater and excessive humidity, whilst the ones in less warm climates need materials and designs that can cope with low temperatures without becoming brittle.

Recent technological advancements include using PC-aided design (CAD) for precise modeling, advanced welding techniques for stronger joints, and the mixing of clever sensors for real-time tracking of vessel conditions. Materials technological know-how has also made good-sized strides, with the improvement of new alloys and composite materials that provide advanced power, corrosion resistance, and weight loss.

Yes, pressure vessels can be significantly custom-designed to meet unique operational requirements. This consists of versions in length, shape, material, and inner additives. However, customization is restricted by safety requirements, cloth homes, and production competencies. Each custom design must nonetheless comply with relevant protection codes and standards, together with ASME, to ensure operational safety and reliability.

Maintenance requirements for pressure vessels encompass ordinary inspections, pressure checking out, and surface examinations for corrosion or harm. The frequency of inspections depends on the vessel’s cloth, utilization, and environmental situations. Generally, pressure vessels ought to go through a radical inspection at least as soon as every 3 years. However, vessels in harsh environments or the ones dealing with unsafe substances can also require greater frequent exams.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.