Table of Contents

TogglePressure vessel pressure is a critical factor in pressure vessel design, safety, and functionality. Whether you’re managing a refinery, power plant, or manufacturing operation, understanding the right pressure levels for your pressure vessels isn’t just about compliance—it’s about safeguarding lives, optimizing performance, and ensuring long-term reliability. Let’s explore what determines pressure vessel pressure, how it’s calculated, and why it matters.

A pressure vessel is a container designed to hold gases or liquids at a pressure significantly different from atmospheric pressure. These vessels are vital to industries like oil and gas, chemical manufacturing, food processing, and energy generation.

Several factors affect pressure vessel pressure, including:

These variables are used to calculate the Maximum Allowable Working Pressure (MAWP), which defines the vessel’s upper safe pressure limit.

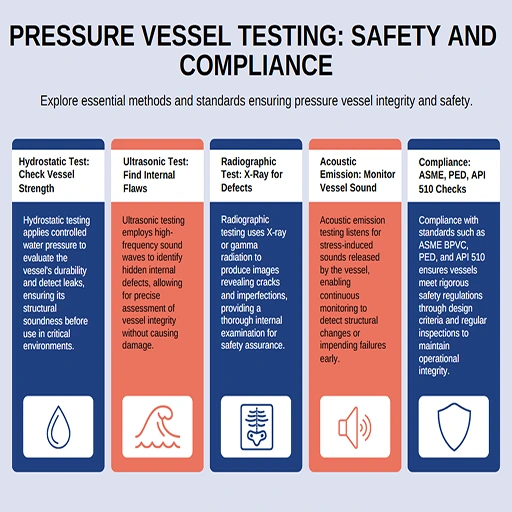

Industry codes establish the rules for determining and verifying pressure vessel pressure. Key standards include:

Selecting the wrong pressure vessel pressure can lead to:

Properly rated vessels ensure long-term safety, performance, and compliance.

Understanding and applying the correct pressure vessel pressure is essential in vessel design and operation. Always consult industry standards, consider environmental and operational factors, and verify through rigorous testing and documentation.

A pressure vessel is typically a cylindrical or spherical container fabricated from high-strength steel, stainless steel, or composite materials. Its design must accommodate internal or external pressures that exceed atmospheric pressure, often significantly. Some common pressure vessel types include:

Each application comes with unique pressure requirements depending on the contents and operating conditions.

Most pressure vessels are designed in cylindrical or spherical shapes because these geometries evenly distribute internal pressure and minimize stress points. The materials are selected based on corrosion resistance, operating temperature, and required pressure rating. Welds, joints, and fittings must also meet strict quality standards to prevent catastrophic failure.

Pressure vessels are never assigned a single pressure number. Instead, several ratings define their performance thresholds:

Also called operating pressure, this is the pressure at which the vessel typically functions under normal conditions. It is intentionally kept below the design pressure to include a safety margin.

The design pressure is the maximum pressure that the vessel is engineered to handle safely, factoring in potential surges or operational anomalies. It’s often slightly higher than the working pressure, typically by 10–20%.

For instance, a pressure vessel may operate at 150 psi but be designed for 165–180 psi.

This is a term defined by the ASME Boiler and Pressure Vessel Code (BPVC), specifically Section VIII. MAWP is the maximum pressure the vessel can withstand at a specific temperature based on material strength, wall thickness, and manufacturing process.

The MAWP is legally enforceable in many regions and is stamped directly on the vessel nameplate, making it the most crucial rating from a compliance standpoint.

Also called hydrostatic or pneumatic test pressure, this is the level at which a vessel is tested during inspection. It is usually 1.3 to 1.5 times the design pressure and ensures the vessel can handle unexpected stress.

Determining what pressure a pressure vessel should be isn’t as simple as applying a one-size-fits-all figure. Several variables come into play:

Gases are compressible and more volatile than liquids, often requiring vessels with higher pressure tolerance. For example:

Pressure ratings must be calculated alongside temperature. As temperature increases, material strength decreases, impacting MAWP. Engineers must evaluate both temperature-pressure curves and material creep limits.

Corrosive environments reduce wall thickness over time. Therefore, vessels operating in such conditions must use corrosion-resistant materials like Inconel, Hastelloy, or stainless steel and may require corrosion allowances in their thickness calculations.

Safety factors are built into every aspect of vessel design to accommodate unexpected stress, miscalculations, or anomalies.

Codes like the ASME BPVC or API 510 (for pressure vessel inspection) ensure standardized design, testing, and inspection. Geographic areas or industries may also impose specific regulations—for example, Europe requires CE marking under the Pressure Equipment Directive (PED).

Some industries—like food and beverage—demand sanitary vessel design, while others, such as chemical processing, require reactive vessel containment. These nuances influence pressure requirements.

Choosing the right pressure level involves careful engineering and regulatory review. Here are the steps most professionals follow:

Answering these questions informs baseline pressure needs.

Engineers select materials based on mechanical properties, corrosion resistance, and compatibility with contents. Using tools like ASME Section II, material strength at various temperatures is assessed to determine wall thickness.

For carbon steel at 600°F, the yield strength might drop significantly, requiring thicker walls.

ASME Section VIII, Division 1 (or Division 2 for higher-stress applications) provides calculation methods, formulas, and design criteria. These include:

For complex shapes or high-pressure systems, computer simulations can assess how pressure is distributed and help optimize wall thickness and reinforcement.

Once built, the vessel must pass hydrostatic or pneumatic pressure tests at 1.3–1.5 times its design pressure. It will also undergo:

Only then will the pressure rating be certified and nameplated.

For more technical insights, check out the National Board Inspection Code (NBIC), which provides additional safety guidelines.

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Typical working pressure varies by application but generally ranges between 15 psi to over 3,000 psi for industrial systems.

MAWP stands for Maximum Allowable Working Pressure and is the highest pressure the vessel can safely withstand at a specified temperature.

Design pressure includes a safety margin above the working pressure to accommodate unexpected surges or loads.

In the U.S., ASME Boiler and Pressure Vessel Code (Section VIII) is the primary standard.

No. Operating above design pressure risks failure and violates safety codes.

Fluid type, operating temperature, corrosion resistance, and required safety margins all impact rating selection.

Yes. Most are hydrostatically or pneumatically tested at higher-than-working pressures to ensure integrity.

It may rupture or leak, causing safety hazards, downtime, and regulatory violations.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.