Table of Contents

ToggleSkids, often confused with pallets, have been around for centuries, serving as a foundational tool for moving heavy objects. Their significance lies not just in their ability to bear weight but also in the flexibility they offer in terms of storage and transportation. Whether it’s a construction site, a bustling warehouse, or a high-tech manufacturing unit, skids have found their place, proving their indispensability time and again.

Therefore, understanding the applications of skids is crucial for businesses aiming to optimize their operations. By delving into the world of skids, one can uncover the myriad ways they contribute to smoother workflows, reduced costs, and enhanced safety measures.

Aircraft Compatibility: In air cargo logistics, skids help standardize cargo loads, ensuring they fit within aircraft cargo holds. This simplifies loading and unloading at airports.

Skids distribute the weight of the load primarily along the edges, which may not be suitable for fragile or irregularly shaped items.

Design and Structure:

Forklift and Jack Compatibility:

Versatility:

Load Stability:

In conclusion, skids are not mere platforms; they are enablers of progress and efficiency. They are the unsung heroes of material handling, supporting industries across the globe in their quest for smoother workflows, cost-effective solutions, and a greener future. As we continue to innovate and adapt, let skids serve as a reminder of the timeless ingenuity that drives human progress, ensuring that the path forward is marked by sustainability and success.

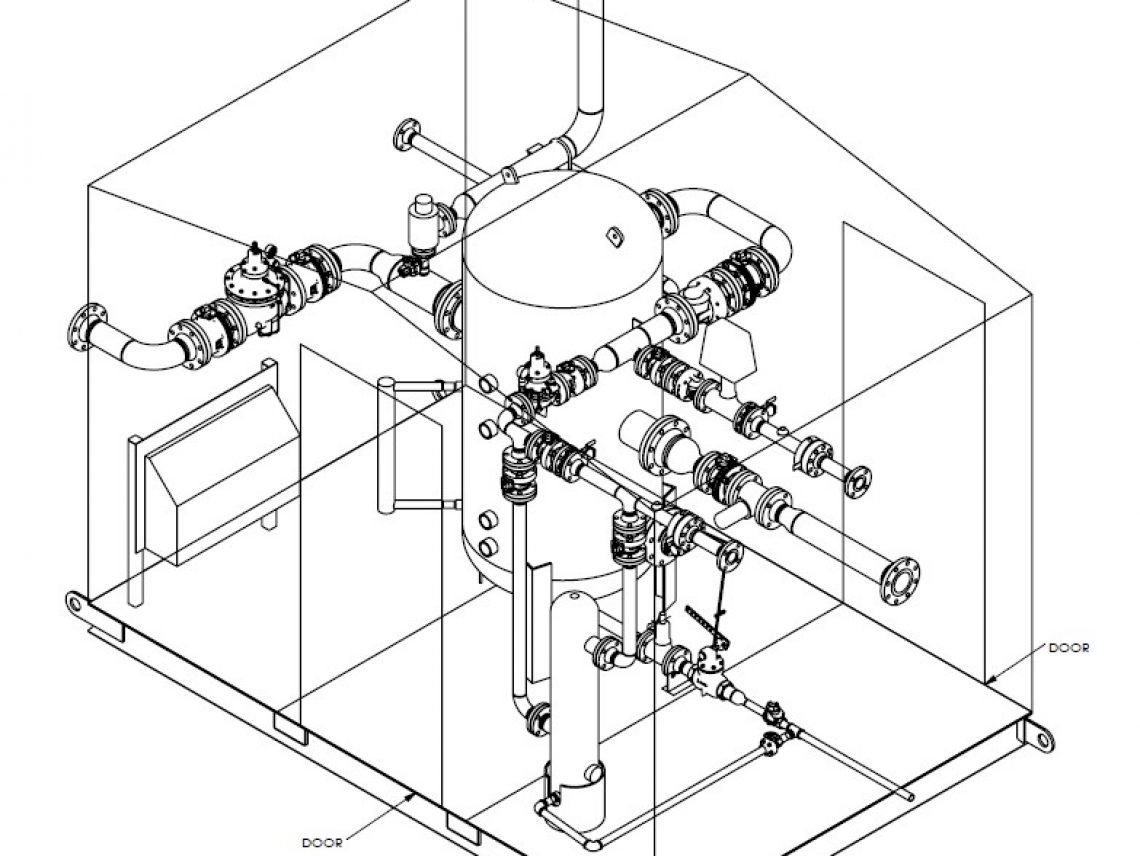

Skids refer to a structural frame that supports pressure vessels or other heavy equipment. In pressure vessel applications, skids are crucial for providing a stable and secure base. They facilitate the safe transportation, installation, and operation of pressure vessels, especially in industrial settings where mobility and space optimization are key concerns.

Absolutely. Skids are often custom-designed to meet the specific needs of a pressure vessel system. Factors like the size, weight, and operational requirements of the vessel, as well as the environmental conditions of the installation site, are considered. Custom skids ensure that the pressure vessel is adequately supported and remains stable during operation and transportation.

Skids play a vital role in enhancing both safety and efficiency. By providing a stable platform, they reduce the risk of vessel movement and potential damage. This stability is crucial for maintaining the integrity of the vessel, especially under high-pressure conditions. Additionally, skids often incorporate features that facilitate easier access for maintenance, improving operational efficiency.

The choice of material for skids largely depends on the application and environment. Common materials include structural steel and aluminum, known for their strength and durability. The selection is influenced by factors like the weight of the pressure vessel, corrosion resistance requirements, and the need for mobility.

The design of a skid impacts the performance significantly. A well-designed skid ensures that the pressure vessel is level and stable, which is crucial for its proper functioning. It also affects the ease of installation and maintenance. A poorly designed skid can lead to operational inefficiencies, increased wear and tear, and even safety hazards.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.