A reactor pressure vessel, often referred to as the heart of a nuclear power plant, is a robust container designed to house the reactor core and its associated components. Specifically, it plays a pivotal role in containing the nuclear reactions and ensuring the safety of the surrounding environment. At the same time, Red River LLC understands the intricacies of designing and manufacturing these vessels, ensuring they meet the highest standards of quality and safety.

The significance of reactor pressure vessels in nuclear power plants cannot be overstated. For example, these vessels are responsible for containing the radioactive materials and the intense heat generated during nuclear fission. In addition, their robust design ensures that radiation does not escape into the environment, safeguarding both plant workers and the surrounding communities.

Furthermore, with industries like oil and gas, power generation, and minerals/elements relying heavily on energy, the role of nuclear power plants—and by extension, reactor pressure vessels—becomes even more critical. Therefore, Red River, with its dedication to American values like work ethic, reputation, and a firm handshake, is committed to serving these industries by providing top-notch reactor pressure vessels. As a result, our clients, ranging from international entities to startups, trust us for our unwavering commitment to safety and quality.

Furthermore, with industries like OIL AND GAS, POWER GENERATION, and MINERALS/ELEMENTS relying heavily on energy, the role of nuclear power plants and, by extension, reactor pressure vessels, becomes even more critical. Red River LLC, with its dedication to American values like Work Ethic, Reputation, and a Firm Handshake, is committed to serving these industries by providing top-notch reactor pressure vessels. Our clients, ranging from international entities to startups, trust us for our unwavering commitment to safety and quality.

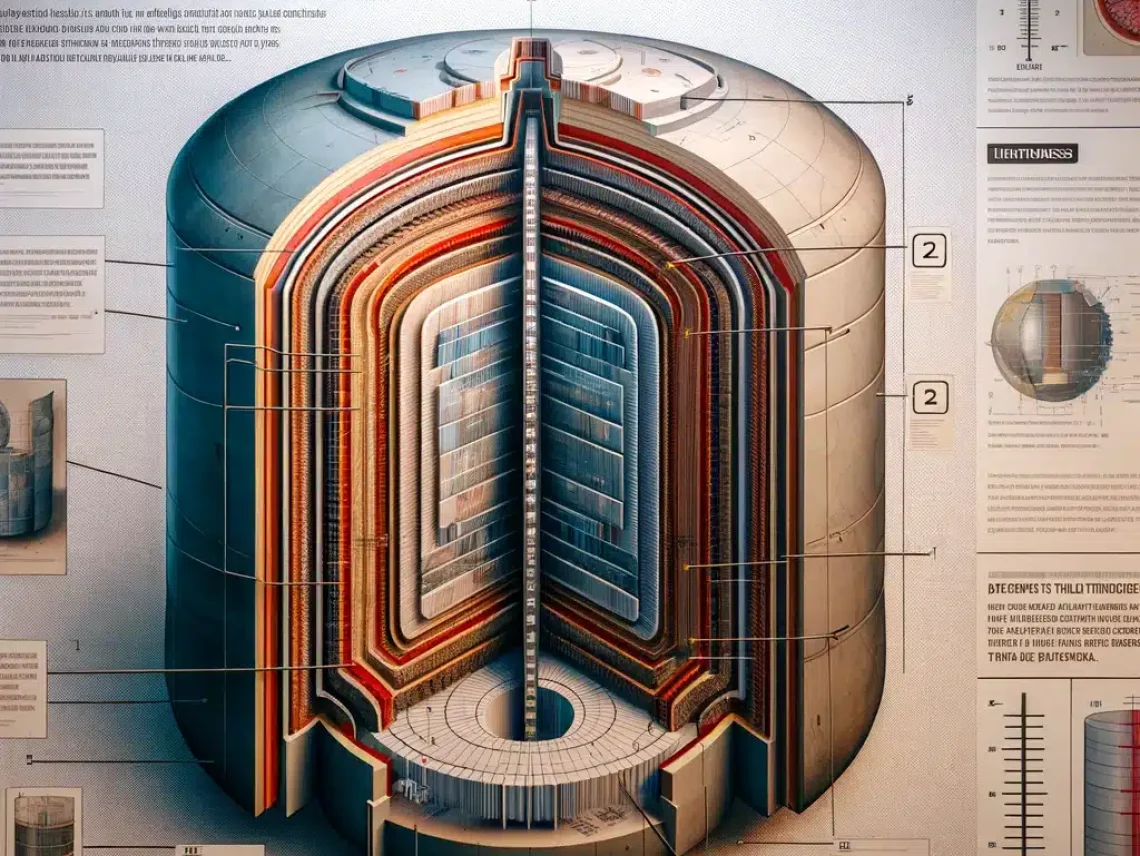

A reactor pressure vessel is not just a simple container; instead, it is a marvel of engineering comprising various components, each playing a crucial role in the vessel’s functionality. Specifically, some of the key components include:

Clearly, understanding the depth and dimensions of nuclear reactor pressure vessels is crucial for their safe and efficient operation. For this reason, Red River LLC prides itself on its expertise in determining the thickness of reactor pressure chambers and ensuring they adhere to the nuclear reactor vessel dimensions and thickness standards.

With this in mind, Red River LLC is your ideal partner for all your reactor pressure vessel needs. Whether you’re looking to understand the standard thickness for nuclear reactor vessels or seeking a partner who values trust and long-term relationships, we’re here for you. Reach out to us today and experience the Red River difference.

The choice of material is paramount in determining the thickness of reactor vessels. In particular, materials like stainless steel, renowned for their durability and resistance to radiation, are often preferred. Indeed, the material’s inherent properties influence the vessel’s ability to withstand internal pressures and temperatures.

Reactor vessels operate under extreme conditions. The internal pressure and temperatures, resulting from nuclear reactions, directly influence the required vessel thickness. A vessel designed for higher pressures necessitates greater thickness to ensure safety.

Regulatory bodies set stringent standards for reactor vessel thickness. Adherence to these standards ensures the vessel’s integrity and the safety of the surrounding environment.

Modern methods such as ultrasonic testing (UT) and radiographic testing (RT) are widely used to measure the thickness of reactor vessel walls accurately:

Ultrasonic Testing (UT): This non-destructive testing method uses high-frequency sound waves to measure the thickness of the vessel wall. By measuring the time taken for the sound waves to travel through the material and reflect back, technicians can accurately determine wall thickness without needing to access both sides of the wall.

Radiographic Testing (RT): In radiographic testing, X-rays or gamma rays are used to create an image of the vessel wall. The resulting image highlights any variations in thickness or potential defects within the material, providing valuable insights into the structural health of the vessel.

Laser Scanning and 3D Modeling: Some advanced facilities employ laser scanning and 3D modeling to measure and analyze reactor vessel thickness. This method creates a comprehensive map of the vessel, enabling precise monitoring over time.

Accurate thickness measurements are essential to the safety and efficiency of reactor vessels. Incorrect thickness can lead to:

Different reactor models and types require varying wall thicknesses based on their operational parameters and intended use:

By analyzing thickness variations in different models, engineers gain insights that inform optimal design practices and help tailor maintenance protocols to specific reactor types.

Organizations like the American Society of Mechanical Engineers (ASME) set international standards for reactor vessel thickness:

These global benchmarks provide consistency, ensuring reactor vessels can safely operate under high-pressure and high-temperature conditions.

Thickness requirements vary depending on the specific type and design of the reactor:

These design considerations ensure the vessel’s wall thickness can withstand the unique challenges posed by each reactor type.

Thickness standards for reactor vessels have evolved over the years as technology advances and understanding of reactor mechanics improves:

Continuous research and development allow standards organizations to set thickness guidelines that adapt to advancements in nuclear technology, enhancing reactor safety.

Adequate vessel thickness directly correlates with reactor lifespan, ensuring operational efficiency over extended periods.

A reactor vessel’s primary role is to contain radiation. Its thickness plays a crucial role in preventing radiation leaks, safeguarding both plant workers and the environment.

Historical incidents highlight the importance of maintaining optimal vessel thickness. Analyzing these cases offers valuable lessons in reactor safety and design.

To ensure reactor vessels maintain their integrity, regular inspections are crucial. These scheduled checks help in the early detection of potential issues, ensuring the vessel’s longevity and safety.

Modern techniques, such as ultrasonic testing and radiographic imaging, are employed to detect wear and tear in reactor vessels. These methods offer precision, ensuring the vessel’s optimal performance.

Any discrepancies in vessel thickness are addressed promptly. Remedial measures, including reinforcement or vessel replacement, are undertaken based on the severity of the discrepancy.

Innovations have introduced materials with enhanced durability and radiation resistance, ensuring increased vessel thickness and heightened safety.

Continuous research has led to design modifications, ensuring reactor vessels last longer while maintaining peak performance.

The reactor vessel industry is poised for groundbreaking advancements, with trends focusing on sustainability, efficiency, and enhanced safety protocols.

Red River LLC boasts a rich history of reactor vessel assessments, reflecting our commitment to excellence and safety in the nuclear industry.

Our clientele’s glowing testimonials and success stories stand testament to our unparalleled expertise and dedication to reactor vessel manufacturing and analysis.

With a blend of experience, innovation, and a client-centric approach, Red River LLC emerges as the preferred choice for all reactor vessel requirements.

The primary materials used in manufacturing reactor pressure vessels are typically high-strength steel alloys, often combined with other elements like nickel or chromium. These materials are chosen for their durability, resistance to radiation, and ability to withstand the extreme conditions inside a reactor, such as high temperatures and pressures.

Reactor pressure vessels are specifically designed to handle the extreme conditions generated during nuclear reactions. Their thickness, material selection, and structural integrity are meticulously planned to contain the heat and pressure. Additionally, they are often surrounded by cooling systems that help dissipate the heat, ensuring the vessel remains within safe operational limits.

Yes, different types of nuclear reactors, such as pressurized water reactors (PWRs) and boiling water reactors (BWRs), have distinct designs for their reactor pressure vessels. These designs take into account the specific operational parameters and requirements of each reactor type, ensuring optimal performance and safety.

Regular inspections of reactor pressure vessels are crucial to ensure their safety and longevity. Typically, inspections are conducted during planned maintenance outages, which can occur every 12 to 24 months. However, the frequency might vary based on the reactor’s age, operational history, and any anomalies detected during previous inspections.

The thickness of a reactor pressure vessel is crucial for its ability to contain the intense pressure and radiation inside. If the vessel’s thickness is not maintained or if there are discrepancies, it could lead to potential hazards such as radiation leaks, vessel rupture, or even a nuclear meltdown. Ensuring the correct thickness and addressing any discrepancies promptly is vital for the safety of both the nuclear facility and the surrounding environment.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.