Understanding Thick Pressure Vessel Theory

Table of Contents

ToggleIntroduction to Thick-Walled Pressure Vessels

Let’s begin with the fundamentals. Thick-walled pressure vessels are engineering marvels designed to include fluids or gases at high pressures. These vessels have walls which are, because the call indicates, substantially thicker than their thin-walled counterparts. The cause at the back of this extra thickness is to ensure the structural integrity and safety of the vessel beneath extreme pressure conditions.

Thick pressure vessels find their packages in an extensive variety of industries, from oil and gasoline to energy technology and the past. Understanding their essential ideas is crucial for every person worried in those sectors, and that’s where Red River is available. We’ll destroy the concept so that you don’t need to.

Importance in Industrial Applications

Now, you might marvel at why those thick-walled pressure vessels matter so much. The answer lies in their vital role across numerous industrial programs. Whether you’re managing the exploration and manufacturing of oil and gas, producing strength for groups, or working with minerals and factors, pressure vessels play a pivotal function in maintaining the glide and containment of essential materials.

Imagine a state of affairs where the integrity of a pressure vessel is compromised—it’s not simply an inconvenience, it’s a capability disaster ready to take place. That’s why knowledge of the theory in the back of these vessels is critical. At Red River, we don’t simply manufacture pressure vessels; we ensure they meet the very best requirements of safety and performance.

Evolution of Pressure Vessel Design

Over the years, pressure vessel layout has evolved significantly. The early days saw easy, rudimentary designs, however today’s vessels are a testament to engineering excellence. At Red River, we appreciate the journey and the innovations that have fashioned this field.

With advancements in materials, manufacturing techniques, and computational tools, thick-walled pressure vessels have come to be safer, greener, and adaptable to diverse enterprise desires. We’ll take you through this charming adventure, highlighting the milestones and breakthroughs that have made those vessels what they are nowadays.

Fundamentals of Thick Pressure Vessel Theory

To hold close the thick pressure vessel concept, it is essential to dive into the fabric pressure evaluation. The forces and pressures these vessels endure require deep information on the way distinctive substances reply. At Red River, we’re properly versed in assessing the stress factors that materials endure, ensuring the protection and sturdiness of our vessels.

Principles of Pressure Resistance

Pressure resistance is at the core of thick-walled pressure vessels. These vessels need to face up to immense inner and external pressures. Our knowledge lies in making use of the principles of pressure resistance to our designs, making sure that they can perform reliably under the harshest situations.

Comparison with Thin-Walled Vessel Theory

Thin-walled and thick-walled vessels are two distinct worlds. Understanding the variations among them is critical. Thick-walled vessels provide robustness and sturdiness, but they come with specific challenges. We’ll examine these theories that will help you respect the blessings of thick-walled vessels.

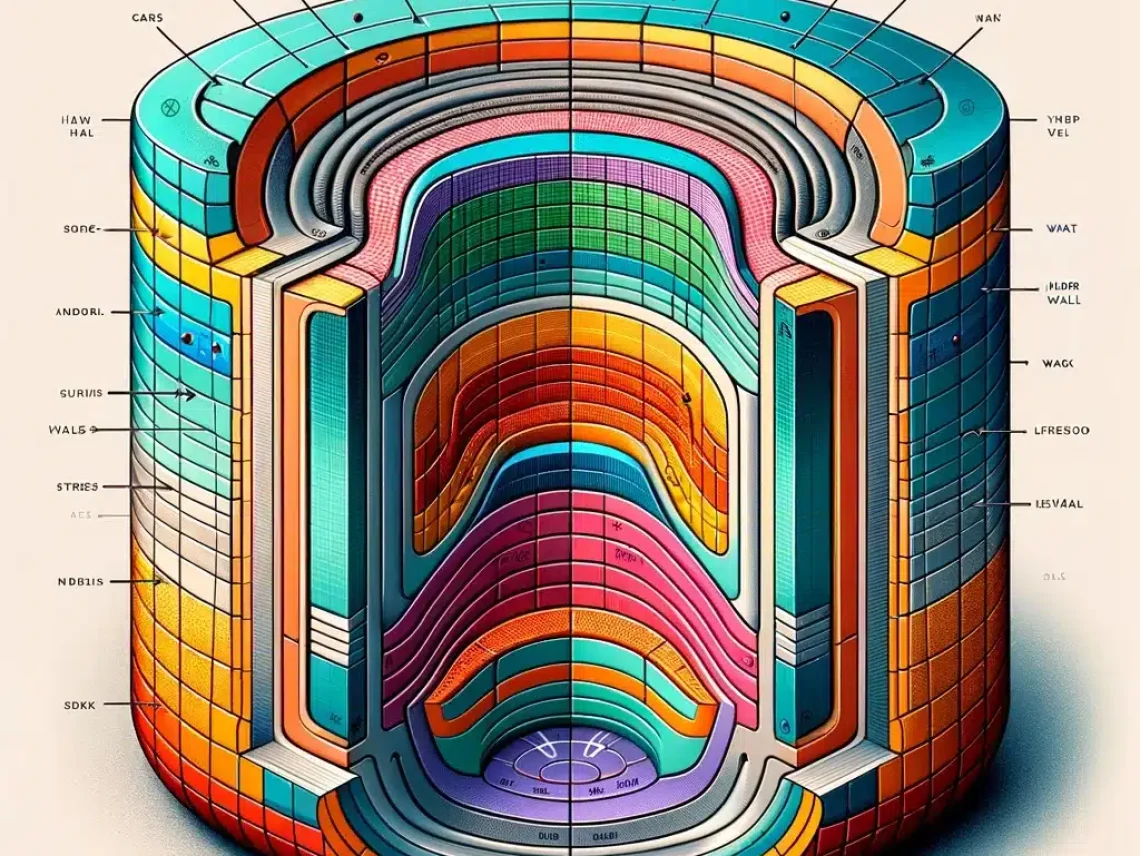

Radial and Circumferential Stress Explained

Radial and circumferential pressure are critical additives of the thick pressure vessel principle. We’ll destroy those pressure kinds, presenting insights into how they have an effect on vessel overall performance and durability.

Advanced Computational Methods in Stress Analysis

In the present-day generation, advanced computational techniques have revolutionized pressure evaluation. At Red River, we leverage the current generation to carry out in-depth pressure analysis, permitting us to optimize vessel designs for efficiency and safety.

Design Techniques for Thick-Walled Vessels

Innovation drives development in pressure vessel layout. We explore progressive approaches that set our vessels apart, from custom internals to weather control solutions, ensuring that our designs meet your particular necessities.

Safety Standards and Compliance

Safety is paramount in our designs. We adhere to the highest safety requirements and compliance protocols, giving you peace of mind knowing that your thick-walled vessels meet all important regulations.

Material Selection for Durability and Efficiency

The choice of substances can make or damage a thick-walled vessel. We guide you through the cloth choice procedure, ensuring that the chosen substances beautify sturdiness and operational performance.

Mechanics of Thick-Walled Pressure Vessels

Elastic and plastic deformation are essential principles in the mechanics of thick-walled pressure vessels. We’ll assist you hold close these ideas, emphasizing their significance in vessel design and performance.

Thermal Stress Considerations

Temperature variations can exert considerable pressure on thick-walled vessels. Our knowledge lies in thinking about thermal pressure elements, ensuring that vessels can function reliably throughout a huge variety of temperatures.

Fatigue Analysis in Vessel Walls

Fatigue analysis is essential for assessing how thick-walled vessel partitions resist repeated pressure cycles. We delve into this evaluation, highlighting its importance in ensuring the long-term structural integrity of your vessels.

Structural Integrity Analysis of Thick Pressure Vessels

Ensuring the durability of thick pressure vessels calls for proactive preservation techniques. We offer insights into renovation practices that maximize the lifespan of your vessels.

Inspection and Testing Protocols

A thorough inspection and trying out are cornerstones of structural integrity analysis. Our protocols assure that your vessels undergo rigorous evaluation, adhering to the best industry requirements.

Case Studies on Vessel Failures

Learning beyond failures is critical. We present real-global case studies on vessel disasters, showcasing the significance of sound design, evaluation, and upkeep practices.

Advanced Topics in Thick Pressure Vessel Theory

Innovations in vessel fabrication are at the forefront of thick-pressure vessel theory. We’ll explore the latest advancements in fabrication techniques and how they contribute to improved vessel performance and durability. At Red River, we embrace innovation to deliver cutting-edge solutions.

Future Trends in Pressure Vessel Design

Destiny holds thrilling possibilities for pressure vessel layout. We’ll provide insights into rising developments and technologies to form the enterprise. Stay ahead of the curve with our ahead-searching angle.

Practical Applications of Thick Pressure Vessel Theory

Thick-walled pressure vessels locate programs in numerous industries, every with unique demands. We’ll delve into enterprise-specific use instances, demonstrating how our vessels meet the particular wishes of customers in oil and gas, power technology, minerals, and more.

Challenges in Aerospace and Submarine Engineering

Aerospace and submarine engineering gift unique demanding situations for pressure vessel layout. We’ll discover those challenges and exhibit how our expertise addresses them, ensuring protection and performance in stressful environments.

Role in the Energy Sector and Power Plants

The strength zone is based on robust pressure vessels to generate strength. We’ll talk about the vital role of thick-walled vessels in power plants and how our solutions contribute to dependable energy manufacturing.

Learning Resources on Thick Pressure Vessel Theory

For those trying to deepen their know-how of thick pressure vessel ideas, we offer hints on crucial books and journals. Explore these treasured assets to stay informed and live beforehand inside the subject.

Online Courses and Workshops

Continuous gaining of knowledge is fundamental. We highlight online guides and workshops that provide complete education on thick-walled pressure vessels. Invest in your expert development with those valuable getting-to-know possibilities.

Leading Research Institutions and Experts

Connect with the leaders in thick pressure vessel ideas. We’ll introduce you to renowned studies institutions and professionals who are pushing the boundaries of understanding in this field. Join the conversation and live knowledgeable approximately state-of-the-art traits.

Need a reliable partner?

Frequently Asked Questions (FAQs) About Thick Pressure Vessel Theory

What is the primary purpose of using thick-walled pressure vessels?

Thick-walled pressure vessels are more often than not used to include fluids or gases at excessive pressures competently. Their thicker walls are designed to face up to the structural pressures related to those excessive-pressure environments, ensuring the protection and integrity of the vessel.

How does the stress analysis differ in thick-walled pressure vessels compared to thin-walled ones?

Pressure analysis in thick-walled pressure vessels entails assessing diverse pressure additives, which include radial and circumferential pressure. Unlike skinny-walled vessels, which rely on simple formulas, thick-walled vessels require extra complicated calculations and frequently involve concerns like material homes and temperature versions.

Can you explain the concept of elastic and plastic deformation in thick-walled pressure vessels?

Elastic deformation in thick-walled pressure vessels refers back to the reversible deformation that happens below load, where the vessel returns to its unique form while the weight is removed. Plastic deformation, however, is irreversible and includes everlasting adjustments in form because of immoderate pressure.

How do pressure vessel materials impact their performance?

The choice of substances for pressure vessels is critical. Materials ought to be selected based on factors like the kind of fluid or fuel being contained, temperature, and pressure levels. Proper cloth selection guarantees the vessel’s sturdiness, performance, and safety.

What are some emerging trends in pressure vessel design?

Emerging tendencies in pressure vessel layout include the combination of advanced computational strategies for pressure analysis, the use of sustainable materials and manufacturing strategies to lessen the environmental effect, and the improvement of clever vessels with sensors for actual-time monitoring and maintenance optimization.

Table of Contents

ToggleRelated Blog Post

- What is the theory of air vessel?

- Who invented pressure vessels?

- What is the pressure theory in physics?

- What is the ideal pressure vessel shape?

- How does ASME define a pressure vessel?

- What are the material selection for pressure vessel design?

- What is one criterion for design of a safe pressure vessel?

- What is the minimum design pressure of a pressure vessel?

- Which theory of failure is used while designing a pressure vessel Why?

Need Action?

We are here to make it happen. Request a qoute!

Solutions

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.