Efficient water separation in industrial applications protects equipment, reduces downtime, and supports compliance with environmental standards. Methods like gravity separation, coalescers, and filtration are vital to maintaining clean process streams. Poor water removal leads to corrosion, system failure, and regulatory issues. At Red River, we tailor water separation solutions to each operation, ensuring maximum efficiency and long-term reliability.

Understanding Water Separation in Industrial Applications

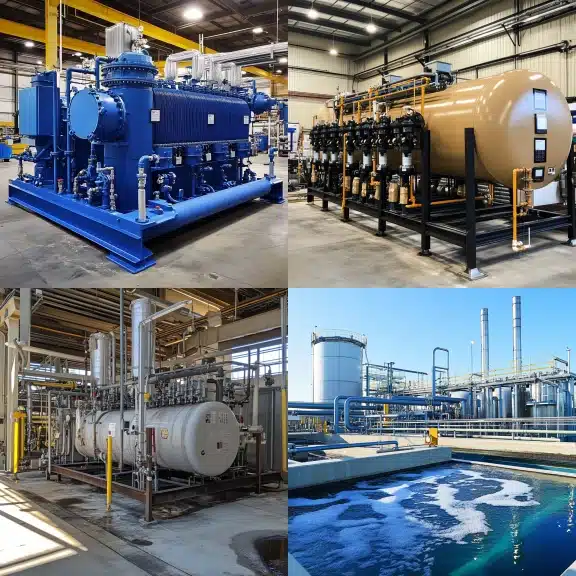

Water separation in industrial applications is crucial for maintaining efficiency, reducing costs, and meeting environmental regulations across industries. At Red River, we understand that water separation in industrial processes is fundamental to maintaining your equipment in good condition and at peak efficiency. This process is vital to your operation, from the pressure vessel to other critical systems. But why is it so important, and what are the best ways to separate the water from a separator? Let’s dive into it.

Innovative Technologies for Water Separation in Industrial Use

Separators play a crucial role in many industrial processes by removing unwanted materials, particularly water, from your process streams. These systems are essential for maintaining the integrity and efficiency of operations, whether in oil and gas, power generation, or other heavy industries.

More than just keeping your systems dry, draining water from a separator protects your investments. Water accumulation can lead to corrosion, decreased efficiency, and even system failure if not promptly addressed. By tuning your equipment for optimal performance, understanding how water extraction is achieved in separator systems becomes crucial.

Common Causes of Water Accumulation in Separators

Various factors contribute to water accumulation in separators, including condensation due to fluctuating temperatures, leaks, poor maintenance, and ineffective separation methods. Over time, these issues degrade the efficiency of the separator, leading to costly repairs and downtime.

To prevent such problems, efficient water removal methods are essential. Applying the right techniques ensures separators perform optimally, avoiding damage and extending the life of your equipment.

Importance of Efficient Water Removal

Efficient water removal is critical for the longevity and performance of your industrial equipment. By employing mechanical methods such as coalescers, filters, and dewatering systems, we offer effective solutions for different industrial settings. At Red River, every job is unique, which is why we tailor our solutions to your specific needs.

Methods to Remove Water from a Separator

Water removal from a separator is crucial for the efficiency and service life of your industrial equipment. At Red River, we employ various methods to best match your specific requirements.

Mechanical Water Removal Methods

Mechanical methods serve as the first line of defense against water accumulation. These techniques leverage physical forces to separate water from other substances within the separator. Approaches such as gravity separation rely on density differences, while centrifugation applies rotational force to isolate heavier particles. Both methods are trusted for their reliability and effectiveness in industrial applications.

Coalescers and Filters in Effective Water Separation

For more efficient water removal, coalescers and filters play a key role. By combining smaller water droplets into larger ones, coalescers simplify the separation process. Meanwhile, filters trap water particles as fluids pass through, ensuring moisture-free outputs. These techniques excel in industries where both purity and efficiency are non-negotiable.

Advanced Technologies for Water Extraction

As water extraction technology evolves, methods such as electrostatic separation and membrane filtration are revolutionizing the industry. These innovative solutions ensure systems remain compliant while handling the most complex separation tasks.

Best Practices for Maintaining a Separator

Proper maintenance of your separator is vital for long-term performance and reliability. At Red River, we emphasize regular upkeep to ensure continued operational efficiency and minimize the costs associated with extended downtime.

Regular Maintenance and Inspection Procedures

Maintaining your separator involves regular inspections for wear, corrosion, and buildup. By servicing components like seals, filters, and internal parts, you can maintain peak efficiency. Consistent inspections reduce the risk of unexpected failures, extending equipment lifespan.

Optimizing Separator Efficiency

Achieving peak efficiency requires fine-tuning your separator’s operation. Adjustments to flow rates, pressure drops, and component configurations enhance performance. These strategies not only improve functionality but also lower energy and operational costs.

Troubleshooting Common Water Removal Problems

Despite proper maintenance, issues may still arise. Problems like water carryover or unexpected pressure drops are often linked to dirty filters or incorrect settings. Utilizing a troubleshooting guide helps operators quickly identify and resolve these issues, ensuring consistent performance.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions

1. What is the most common method for removing water from a separator?

Gravity separation is widely used due to its simplicity and cost-effectiveness. It relies on density differences to allow water to settle at the bottom for easy removal.

2. How can the water removal process in a separator be automated?

Automation uses sensors and control systems to monitor water levels and trigger drainage. This increases efficiency and reduces the need for manual checks.

3. What are the indications that a separator is not adequately removing water?

Common signs include water in the output stream, reduced efficiency, or sudden pressure drops. These issues often point to clogged filters or incorrect flow settings.

4. How do coalescers improve water separation efficiency?

Coalescers combine small water droplets into larger ones, making separation easier. They offer superior performance in high-purity applications.

5. Does the process of water removal from separators have any environmental concerns?

Yes, especially if hazardous materials are present in the extracted water. Proper treatment and disposal are required to meet environmental safety standards.

Key Takeaways

- Efficient water separation prevents corrosion, system damage, and costly downtime.

- Gravity separation, coalescers, and filters are essential for clean and efficient process streams.

- Regular maintenance and inspections improve separator performance and lifespan.

Automation enhances accuracy and reduces manual intervention in water removal. - Red River offers tailored solutions to meet specific industrial separation needs.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

No subpillar set for this blog post.

About Author