Table of Contents

TogglePressurized water storage tanks, also known as pressure vessel water tanks, are designed to safely store water under pressure for various industrial and domestic applications. These tanks ensure efficient water distribution, energy savings, and long-term reliability. Understanding their construction and function is essential for choosing the right storage solution.

be efficiently stored and distributed under pressure. Pressurized water storage tanks are essential in systems where water needs to be pumped to higher elevations or transported over long distances. These tanks are designed to withstand high internal pressures, making them crucial in industries such as oil and gas, power generation, and biogas.

At Red River LLC, we specialize in providing reliable and modern water storage solutions designed to meet the rigorous demands of pressurized applications. Our tanks are engineered to ensure durability, efficiency, and safety in every installation.

For further insights into pressure vessels and their critical role in various industries, you can explore additional resources on pressure vessel systems here.

A pressurized water storage tank is not just a container for holding water; it is an engineered system designed to operate under specific internal pressure conditions. These tanks are made from materials like high-strength steel and composite materials to withstand the immense pressure they are subjected to. Unlike regular water tanks, pressurized water storage tanks are equipped with safety mechanisms like pressure relief valves and automated monitoring systems to ensure safe operation.

For more detailed information on how these tanks are designed to meet high-pressure requirements, read more here.

Is a water tank a pressure vessel? This question often arises in industrial discussions, especially when determining the need for tanks in high-pressure environments. While all water tanks are designed to store water, only those designed to withstand specific pressure levels are classified as pressure vessels. For instance, tanks in industries such as power generation and biogas require pressurized systems to ensure water flow, stability, and operational efficiency.

The design and engineering of these tanks are crucial in ensuring that they meet the safety standards required for such high-pressure applications. For example, in the oil and gas industry, pressurized water storage tanks are designed to withstand extreme conditions, and thus, their structure and materials must be carefully chosen.

To learn more about the role of water tanks in pressure vessel applications, check out our detailed guide here.

Pressure vessels, including pressurized water storage tanks, are designed to operate safely under elevated pressures. Some of the key features of these tanks include:

Wall Thickness: The tank’s walls are designed with sufficient thickness to withstand the internal pressure exerted on them.

Safety Valves: These tanks are equipped with safety valves that relieve pressure if it exceeds safe thresholds.

Durability and Resistance: The materials used in their construction are resistant to corrosion and physical wear, ensuring the tank’s longevity.

Additionally, pressurized water storage tanks include specialized materials that help resist corrosion, which is crucial since water often contains minerals and chemicals that can deteriorate tank materials over time. Learn more about the design principles of pressure vessel water tanks here.

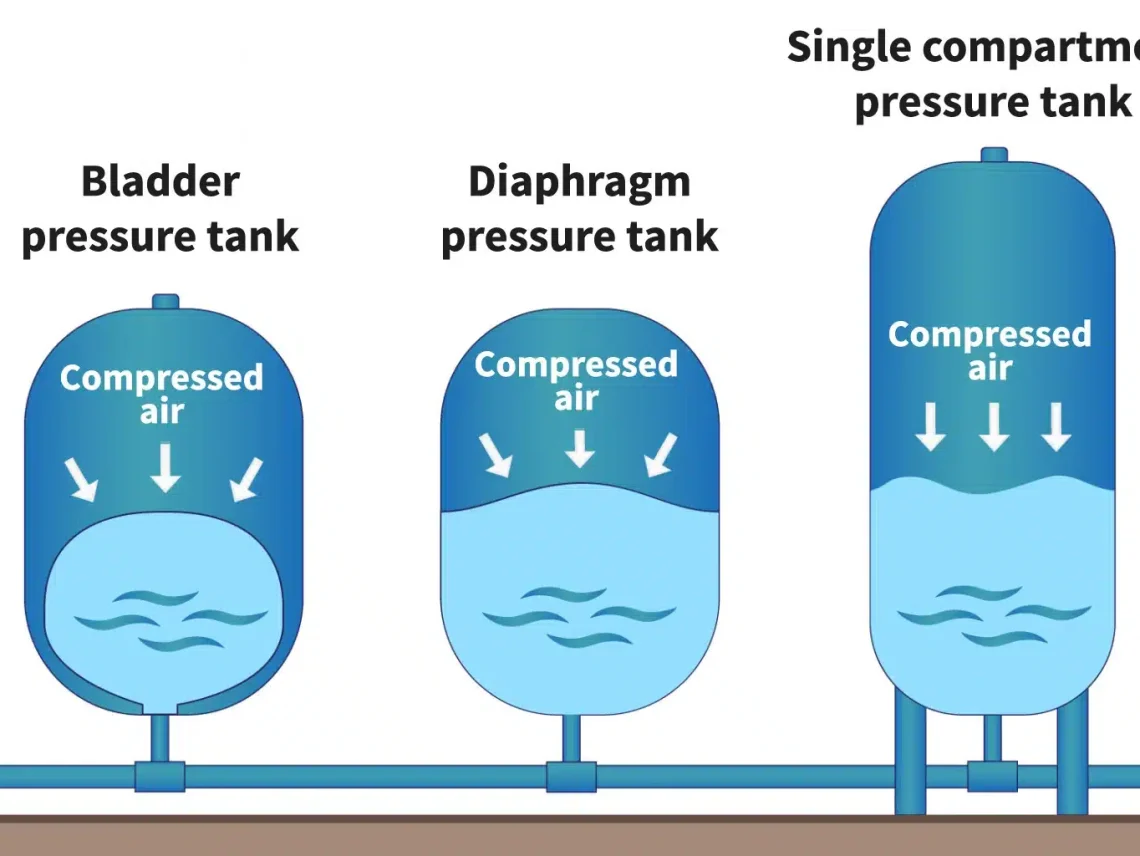

Water tanks vary greatly in design, from gravity-fed tanks that rely on elevation to pressurized systems that are engineered to withstand specific internal pressures. While gravity-fed tanks are sufficient for domestic use in low-pressure scenarios, pressurized tanks are essential for industrial and high-rise applications, where water must be stored and distributed under specific pressure conditions.

Understanding the specific needs of your water system can help determine which type of tank is best suited for your applications. For example, pressurized tanks are designed for use in applications that require a continuous and controlled water flow, such as in high-rise buildings or industrial processing facilities.

For a detailed comparison of water tank types, refer to our article on the different types of pressure vessels.

When designing pressurized water storage tanks, safety is a top priority. These tanks are equipped with multiple mechanisms to ensure safe usage:

Pressure Relief Valves: These valves open automatically if the pressure inside the tank exceeds safe levels, releasing excess pressure to prevent rupture.

Regular Inspections: Routine inspections help ensure that tanks maintain their structural integrity and that safety features, such as valves, are working properly.

Automated Monitoring Systems: High-end tanks are sometimes equipped with automated systems to monitor pressure and temperature in real-time, alerting operators if conditions approach unsafe levels.

By incorporating these safety features, pressurized water storage tanks minimize the risk of failure, ensuring long-term reliability and operational safety.

Pressurized water storage tanks play a crucial role in maintaining the functionality and efficiency of water systems, especially in industries and applications that require water to be stored and distributed under high pressure. Their design, materials, and safety features make them a key component in systems where reliability is essential. Understanding these tanks’ construction and function is vital in ensuring that the right storage solution is selected for each unique application.

If you are looking for reliable pressurized water storage solutions, Red River LLC is here to help. Our expertise in designing and manufacturing pressure vessels ensures you receive high-quality, durable, and efficient water storage systems. Contact us today to discuss your specific needs and find the perfect solution for your project.

A pressurized water storage tank is a container specifically designed to hold water under pressure, ensuring efficient distribution in systems like high-rise buildings and industrial applications.

Pressurized tanks are essential when water needs to be stored and distributed under pressure for consistent flow, especially in applications requiring high water volumes or in industries like oil and gas.

Pressurized water storage tanks are typically made from high-strength steel or composite materials, which are durable and resistant to corrosion.

Pressure relief valves are safety features that automatically release pressure if it exceeds safe levels, preventing potential ruptures or explosions.

Regular inspections are recommended annually, depending on usage and local regulations, to ensure the tank remains in safe working condition.

A gravity-fed tank uses elevation for water flow, while a pressurized tank is designed to store water under pressure, providing controlled distribution even over long distances or heights.

Pressurized water storage tanks are essential for safely storing water under pressure for industrial and high-rise applications.

They are made from durable materials like high-strength steel and composites, ensuring longevity and resistance to corrosion.

Safety features like pressure relief valves and regular inspections help maintain the integrity of the tank.

Pressurized tanks provide more efficient water distribution, reducing the need for additional pumping systems.

Table of Contents

ToggleIn the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.