Every fabrication example involves a combination of essential principles that bring raw materials to life as finished products. Whether it’s a metal bracket, bridge support, or medical device, understanding the key components in each fabrication example helps clarify the complexity of the process.

Below are four foundational concepts found in nearly every fabrication example:

The starting point of any fabrication example is the selection of raw materials. The choice depends on the application, required strength, corrosion resistance, weight, and cost. Common materials used in a fabrication example include:

For instance, a fabrication example for outdoor construction might favor galvanized steel for its durability, while a medical fabrication example could use stainless steel due to its sterilization properties.

No fabrication example is complete without specific manufacturing techniques. These processes shape and assemble the raw materials into their intended forms. The most common processes in a fabrication example include:

Cutting is typically the first step in a fabrication example, using methods like:

Each fabrication example may call for a different cutting method based on precision and material thickness.

Bending reshapes materials without removing any mass and is frequently used in fabrication example scenarios like sheet metal work or enclosures.

Welding is essential in many fabrication example projects, joining parts into a single structure using heat, pressure, or filler materials.

Additional techniques in advanced fabrication example work may include machining, stamping, pressing, and surface finishing.

Behind every successful fabrication example is a well-thought-out design. This stage ensures the final product will perform as intended. Key steps in designing a fabrication example include:

Poor design can ruin a fabrication example, leading to production delays or failed products. Quality engineering ensures that every fabrication example meets standards for strength, durability, and function.

The end product is the result of all the previous stages working in harmony. A finished fabrication example might be:

The quality of the end product in any fabrication example depends on accurate material selection, correct processes, and detailed design. Each phase plays a role in ensuring the final component is reliable, functional, and ready for use.

Understanding what goes into a fabrication example gives insight into how everyday products are created. From bridges and airplanes to farming equipment and medical tools, nearly every industry relies on a fabrication example at some stage.

Learning the key components of a fabrication example—raw materials, processing techniques, engineering design, and final assembly—provides a clear view of the craftsmanship and technology that drives modern manufacturing.

Would you like to follow this with real-world fabrication examples? Let me know and I can expand this further.

Welding is a critical skill in fabrication, forming the backbone of metalworking by enabling materials to fuse together through the application of heat and pressure.

Let’s explore some real-world examples to illustrate how these key concepts come together in practice:

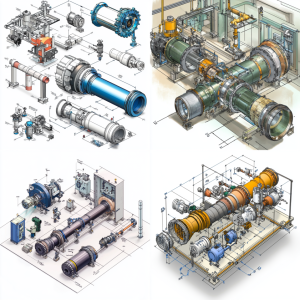

Structural steel fabrication is crucial in constructing buildings, bridges, and other large structures. The process involves taking raw steel beams and columns and transforming them into precisely shaped components ready for assembly on-site. Large steel mills produce the raw steel in standard sizes, which are then sent to fabrication shops.

The fabrication process starts with cutting the steel beams to the specified lengths using saws, plasma cutters, or laser cutters. Next, the steel is shaped through bending, drilling holes for connections, and sometimes adding reinforcing plates. The final step typically involves welding these components together to create more complex structural elements.

Precision is paramount in structural steel fabrication. Each cut, bend, and weld must be accurate to ensure the structural integrity of the building. Stringent **quality control** measures are in place throughout the process, including visual inspections, dimensional checks, and non-destructive testing methods like ultrasonic testing to detect any flaws in the welds. Any deviation from the design specifications can compromise the building’s safety.

Pressure vessels are containers designed to hold liquids or gases at high pressures, commonly used in the oil and gas, chemical, and power generation industries. Fabricating these vessels requires specialized expertise and strict adherence to safety regulations.

The fabrication process begins with selecting the appropriate steel plate based on the pressure and temperature requirements. The plates are then cut to the desired shapes and formed into cylindrical sections using hydraulic presses or rolling machines. These sections are then welded together to create the vessel’s shell.

Welding is a critical aspect of pressure vessel fabrication. Specialized welding techniques are used to ensure the welds are strong and leak-proof. Testing is equally important. After welding, the vessel undergoes rigorous non-destructive testing, such as radiographic testing (X-rays) and hydrostatic testing (filling the vessel with water under pressure) to identify any weaknesses or leaks.

Because pressure vessels operate under high stress, safety requirements are extremely stringent. Regulations dictate the materials used, welding procedures, testing methods, and design specifications. Failure to comply with these regulations can have catastrophic consequences.

Prefabricated pipe spools are sections of piping that are assembled in a controlled shop environment and then transported to the job site for installation. They can be components of pressure vessels or be used in other piping systems. This approach offers several advantages, including faster installation times, improved quality control, and reduced on-site labor costs.

Pipe spools are fabricated by cutting pipes to the required lengths, welding flanges, fittings, and valves to the pipes, and then subjecting the completed spool to testing (e.g., pressure testing, radiography) to ensure integrity. The design phase considers the pipe material, fluid being transported, pressure, and temperature requirements. The completed spools are then labeled and shipped to the construction site, ready for final assembly.

Understanding the fundamentals of fabrication offers numerous benefits. First, it provides an improved understanding of product creation, allowing you to appreciate the complexity and effort involved in transforming raw materials into finished goods. This understanding leads to a better ability to assess quality and durability, enabling you to make more informed decisions when purchasing or specifying fabricated components. Furthermore, it allows for enhanced decision-making by allowing you to identify potential issues early in the process, leading to cost savings and improved outcomes. Finally, it fosters an appreciation for the skill and expertise involved in manufacturing, recognizing the importance of skilled tradespeople in our economy.

In conclusion, the world of fabrication is a fascinating blend of engineering, skilled craftsmanship, and technological innovation. From the structural steel that forms the backbone of our cities to the pressure vessels that power our industries, fabrication plays a critical role in shaping the world around us. By understanding the key concepts, appreciating the meticulous processes involved, and recognizing the importance of quality control, we gain a deeper understanding of the products we use every day. This knowledge empowers us to make informed decisions, value the expertise of fabricators, and appreciate the ingenuity that transforms raw materials into essential components of our modern world. The future of fabrication promises even more advanced techniques and materials, further solidifying its importance across diverse sectors.

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach out to us today and experience the Red River difference. Where American-made products and American Values come together, we care more.

Cutting, bending, welding, machining, and assembly.

Steel, aluminum, stainless steel, and various alloys.

To ensure the safety, durability, and performance of the fabricated product.

Construction, oil and gas, automotive, aerospace, and manufacturing.

Fabrication is a subset of manufacturing, focusing on creating parts or structures from raw materials. Manufacturing encompasses a broader range of processes.

AWS (American Welding Society) certifications for welders are common. ASME certifications are crucial for pressure vessel fabrication.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.