A water separator, also known as a moisture separator or condensate separator, is a tool specifically designed to remove water vapor and liquid droplets from gasoline or air streams. These separators utilize various mechanisms to effectively eliminate unwanted moisture, thereby ensuring that downstream equipment and processes remain unaffected. As a result, industries can maintain efficiency and prevent potential damage caused by excess moisture.

Water separators play a crucial role across a wide range of industries. Below are some key sectors that rely on these devices:

Oil and Gas: In the oil and gas industry, water separators are essential for removing water from natural gas streams before transportation and processing. By eliminating moisture early in the process, they help prevent corrosion in pipelines and equipment, which in turn ensures safer and more environmentally friendly operations.

Water separators successfully take away moisture from gas or air streams, thereby stopping corrosion, rust, and scale formation in the system. As a result, this leads to improved gadget performance, decreased downtime, and a prolonged lifespan. Ultimately, these benefits translate into significant financial savings for businesses.

Moisture in fuel or air streams can accelerate corrosion in pipelines, tanks, and equipment, which, in turn, leads to high-priced upkeep and protection. However, by efficiently removing water droplets, water separators help prevent corrosion and contamination. Consequently, this ensures the integrity of critical infrastructure while also improving operational reliability.

Water separators play an essential role in environmental compliance by ensuring that discharged gases meet regulatory requirements for moisture content. Moreover, by removing excess water vapor, these separators help mitigate the risk of environmental pollution. As a result, they ensure compliance with emissions regulations, safeguarding both public health and the environment.

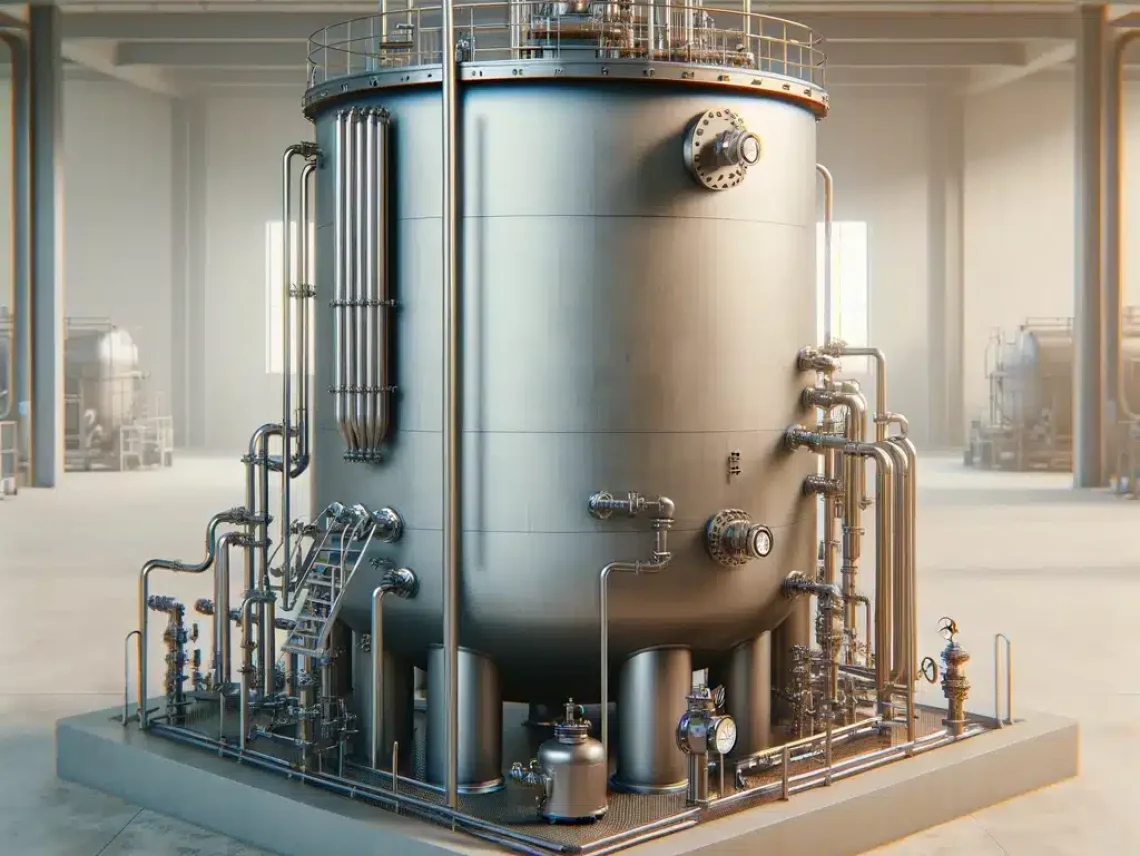

Water separators operate on the principle of gravity separation and coalescence. As the gas or air stream passes through the separator, water droplets present in the stream are separated due to differences in density. Additionally, coalescing media within the separator aids in merging smaller water droplets into larger ones, facilitating their removal from the gas or air stream.

There are several types of water separators, including centrifugal, coalescing, and filtration separators. Centrifugal separators use centrifugal force to separate water droplets from the gas or air stream. Coalescing separators utilize specialized media to merge smaller water droplets into larger ones, making them easier to remove.

Using water separators offers numerous benefits, including improved equipment performance, prevention of corrosion and contamination, environmental compliance, and cost savings on maintenance. By effectively removing moisture from gas or air streams, water separators help enhance equipment reliability, prolong the lifespan, and ensure compliance with regulatory standards, ultimately leading to optimized operational efficiency and reduced maintenance costs.

The frequency of maintenance for water separators depends on various factors, including the operating conditions, the level of contaminants present in the gas or air stream, and the manufacturer’s recommendations. Generally, it is advisable to conduct regular inspections and maintenance checks to ensure optimal performance.

While water separators are primarily designed to remove water from gas or air streams, some models may also have the capability to remove oil droplets, depending on their design and specifications. However, specialized oil-water separators are typically used for applications where oil removal is a primary concern, such as in wastewater treatment facilities or oil refineries.

In the realm of industrial solutions, Red River emerges as a pioneer, offering a diverse range of custom-engineered products and facilities. Among our specialties is the design and production of Custom/OEM Pressure Vessels, meticulously crafted to meet individual client requirements, ensuring performance under various pressure conditions. Our expertise extends to the domain of prefabrication, where Red River leads with distinction.

The company excels in creating prefabricated facilities, modules, and packages, reinforcing its stance as a forerunner in innovation and quality. This proficiency is further mirrored in their Modular Skids offering, where they provide an array of Modular Fabricated Skid Packages and Packaged equipment. Each piece is tailored to client specifications, underlining their commitment to delivering precision and excellence in every project they undertake.