What are the Control Measures of Pressure Vessels? | Red River LLC

Understanding the Importance of Pressure Vessel Control

Pressure vessels are critical components in various industries, from oil and gas to power generation. Their role in containing gases or liquids at high pressures means that any failure can have significant consequences. That’s why understanding and implementing effective control measures for pressure vessels is not just a regulatory requirement; it’s a moral imperative. At Red River, we don’t just manufacture pressure vessels; we craft safety assurances. Our approach to pressure vessel safety measures and controls is comprehensive, ensuring that every vessel we produce meets the highest standards of safety and reliability.

The Role of Red River LLC in Ensuring Pressure Vessel Safety

At Red River LLC, we pride ourselves on being more than just a manufacturer; we are a partner in your safety journey. Our team, led by industry veterans like Reilly Sasse, is dedicated to ensuring that every pressure vessel we produce adheres to the strictest safety protocols for managing pressure vessels. We incorporate the best practices in pressure vessel regulation and operational control measures, ensuring that our products are not only compliant but also set the benchmark for industry standards. Our dedication to safety is reflected in our meticulous approach to every project, whether it’s for the oil and gas sector, commercial/public works, or biogas industries.

Key Principles of Pressure Vessel Safety Management

Safety in pressure vessel manufacturing is not a one-time event but a continuous process. At Red River, we believe in the principles of continuous improvement, accountability, and proactive risk management. Our safety management system encompasses everything from design and fabrication to inspection and maintenance. We adhere to stringent pressure vessel compliance and safety standards, ensuring that every product we deliver is synonymous with reliability and safety. Our commitment to these principles is not just about meeting industry standards; it’s about setting them.

Overview of Pressure Vessel Regulations

National and International Standards for Pressure Vessels

National and international standards for pressure vessels are designed to ensure a uniform level of safety and performance worldwide. These standards cover everything from material selection to testing procedures, ensuring that pressure vessels can safely withstand the rigors of their intended use. Adhering to these standards is not just about compliance; it’s about upholding a global commitment to safety and quality.

Compliance with ASME Boiler and Pressure Vessel Code

The ASME Boiler and Pressure Vessel Code (BPVC) is a globally recognized standard for the design, fabrication, and inspection of boilers and pressure vessels. Compliance with this code is essential for ensuring the structural integrity and safety of pressure vessels. It sets rigorous guidelines that manufacturers like Red River LLC must follow, covering all aspects of construction, from material selection to welding practices.

The Impact of OSHA Guidelines on Pressure Vessel Safety

The Occupational Safety and Health Administration (OSHA) guidelines play a pivotal role in ensuring workplace safety around pressure vessels. These guidelines provide comprehensive directives on operational safety, employee training, and emergency handling, significantly influencing the safety protocols in the pressure vessel industry. Adherence to OSHA guidelines is critical for minimizing risks and protecting workers.

Design and Construction Controls for Pressure Vessels

Advanced Materials and Design Techniques for Safety

Incorporating advanced materials and innovative design techniques is key to enhancing the safety and efficiency of pressure vessels. At Red River LLC, we leverage cutting-edge technology and materials that offer superior strength, durability, and resistance to various stresses, ensuring our pressure vessels are equipped to handle demanding conditions.

Ensuring Structural Integrity in Pressure Vessel Design

The structural integrity of pressure vessels is paramount. This involves rigorous analysis and testing to ensure that the design can withstand high pressures and harsh operational environments. Our engineering team focuses on creating designs that not only meet but exceed safety standards, ensuring long-term reliability and performance.

Quality Assurance in Pressure Vessel Fabrication

Quality assurance during the fabrication of pressure vessels is a critical step in our manufacturing process. This includes stringent inspections, testing of materials, and adherence to precise fabrication standards. Our commitment to quality assurance means that every pressure vessel we produce at Red River LLC is built to the highest standards of safety and reliability.

Operational Control Measures for Pressure Vessels

Routine Inspection and Maintenance Strategies

Routine inspection and maintenance are vital for the long-term safety and functionality of pressure vessels. These strategies involve regular checks to identify and address potential issues before they escalate into major problems. At Red River LLC, we emphasize the importance of proactive maintenance to extend the life of our pressure vessels and ensure continuous safe operation.

Real-time Monitoring and Control Systems

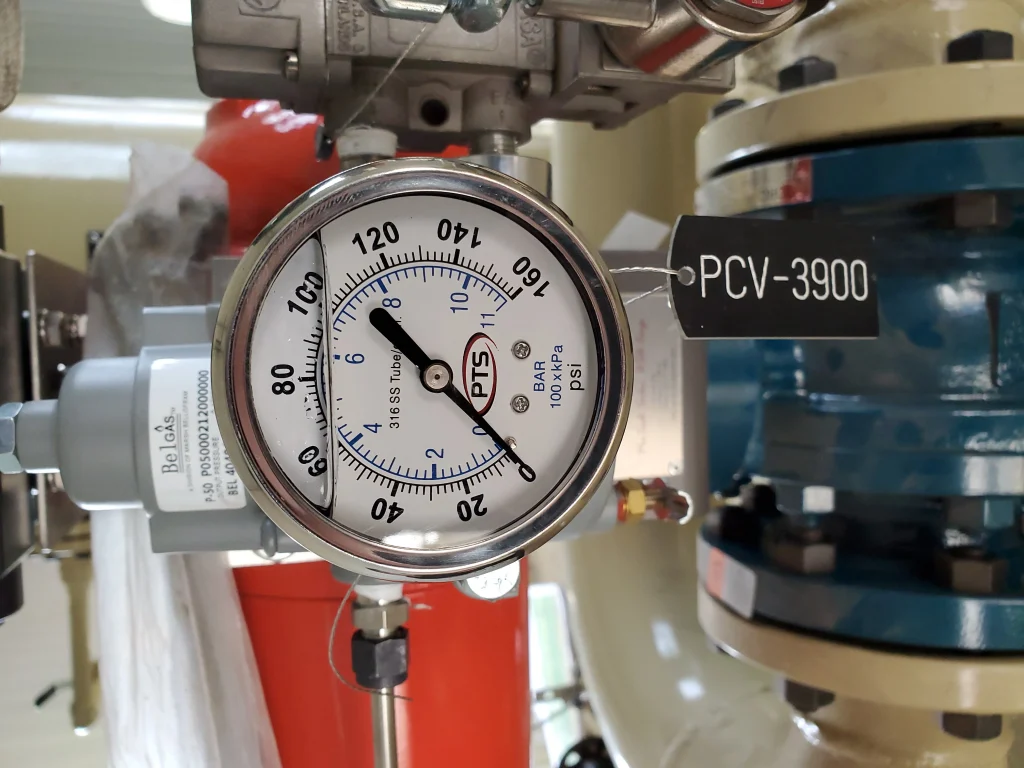

Implementing real-time monitoring and control systems is an effective way to continuously oversee the operational health of pressure vessels. These systems provide immediate data on the vessel’s performance, allowing for quick responses to any changes or anomalies. This level of monitoring is crucial for early detection and resolution of potential issues.

Emergency Response Protocols for Pressure Vessel Failures

Despite all precautions, emergencies can occur. Having robust emergency response protocols in place is essential for effectively managing pressure vessel failures. These protocols outline the steps to be taken in the event of an incident, ensuring quick and efficient responses to minimize risk and damage. At Red River LLC, we prioritize the development and regular review of these protocols to ensure the highest level of preparedness.

Risk Management in Pressure Vessel Operations

Identifying and Assessing Potential Risks

The first step in risk management is to identify and assess potential risks associated with pressure vessel operations. This involves analyzing operational processes, understanding the properties of materials handled, and recognizing environmental factors that could contribute to potential hazards.

Implementing Risk Mitigation Strategies

Once risks are identified, implementing mitigation strategies is crucial. This includes designing safety protocols, emergency response procedures, and regular maintenance schedules to minimize risk and ensure safe operations.

Regular Safety Audits and Reviews

Conducting regular safety audits and reviews is vital to ensure ongoing compliance with safety standards and regulations. These audits help in identifying areas for improvement and updating risk management strategies as necessary.

Training and Personnel Competency

Importance of Skilled Personnel in Pressure Vessel Management

Skilled personnel are essential in managing pressure vessels safely. Their expertise and understanding of the systems play a significant role in ensuring operational safety and efficiency.

Training Programs for Operational Safety

Comprehensive training programs are crucial for equipping staff with the necessary skills and knowledge for safe pressure vessel operations. These programs should cover operational procedures, safety protocols, and emergency response tactics.

Certification and Continuous Learning for Staff

Encouraging continuous learning and certification ensures that staff remain knowledgeable about the latest technologies and safety practices in pressure vessel management.

Pressure Vessel Safety Equipment and Accessories

Essential Safety Accessories for Pressure Vessels

Safety accessories, such as pressure relief valves, gauges, and safety interlocks, are essential for monitoring and maintaining the safe operation of pressure vessels.

Advanced Technology in Pressure Vessel Safety

Leveraging advanced technology in safety systems, like automated monitoring and control systems, enhances the safety and efficiency of pressure vessel operations.

Regular Upgrades and Maintenance of Safety Equipment

Regular upgrades and maintenance of safety equipment ensure that these systems function correctly and provide reliable safety measures.

Documentation and Record Keeping

Importance of Accurate Documentation in Safety Compliance

Accurate documentation ensures compliance with safety regulations and standards. It serves as a record of maintenance, inspections, and modifications made to pressure vessels.

Record Keeping Best Practices

Best practices in record-keeping involve maintaining detailed and organized records that are easily accessible for review and audits.

Utilizing Documentation for Continuous Improvement

Documentation is not just for compliance; it’s a tool for continuous improvement, providing insights into operational efficiencies and areas for safety enhancements.

Environmental Considerations and Sustainability

Eco-friendly Practices in Pressure Vessel Management

Adopting eco-friendly practices, such as using environmentally safe materials and reducing waste, contributes to sustainable pressure vessel operations.

Reducing Environmental Impact of Pressure Vessel Operations

Strategies to reduce the environmental impact include optimizing operational efficiency, minimizing emissions, and using renewable energy sources where possible.

Sustainability in the Design and Operation of Pressure Vessels

Sustainability in design and operation involves considering the environmental impact throughout the lifecycle of pressure vessels, from design and manufacturing to decommissioning.

Legal and Ethical Responsibilities

Understanding Legal Obligations for Pressure Vessel Safety

Staying informed about legal obligations, including compliance with national and international standards, is crucial for lawful operation.

Ethical Considerations in Pressure Vessel Management

Ethical considerations involve going beyond compliance, focusing on the broader impact of operations on employees, communities, and the environment.

Navigating Liability and Insurance Aspects

Understanding liability and insurance aspects ensures protection against potential risks and reinforces a commitment to safety and responsibility.

Need a reliable partner?

Red River specializes in the design and manufacturing of pressure vessels. We also fabricate related items such as prefabricated spools and skid packages.

Reach Out to us today and experience the Red River difference. Where American Made and American Values come together, we care more.

Frequently Asked Questions About Pressure Vessels

1: What are the most critical factors to consider when selecting materials for pressure vessels?

When selecting materials for pressure vessels, the most critical factors include the vessel’s operating pressure and temperature, the chemical nature of the contents, corrosion considerations, and the required strength and durability. Materials must be chosen based on their ability to withstand these conditions without degrading. Common materials used include carbon steel, stainless steel, and alloys like Hastelloy, Inconel, and Monel, each offering different benefits in terms of strength, corrosion resistance, and cost-effectiveness.

2: How do pressure vessel design standards ensure safety and reliability?

Pressure vessel design standards, such as the ASME Boiler and Pressure Vessel Code, provide a comprehensive framework for safety and reliability. They cover aspects like material selection, design, fabrication, inspection, testing, and certification. These standards ensure that vessels can withstand the operational pressures and temperatures they will encounter, prevent failures, and protect both the workforce and the environment. Adherence to these standards is crucial for minimizing risks and ensuring long-term operational integrity.

3: What are the typical maintenance requirements for pressure vessels?

Typical maintenance requirements for pressure vessels include regular inspections for corrosion, leaks, and damage; monitoring of pressure and temperature controls; checking and testing safety valves and gauges; and ensuring all seals and gaskets are intact. Scheduled maintenance should also include internal inspections and hydrostatic testing to assess the vessel’s structural integrity. Proper maintenance is crucial for preventing accidents and extending the lifespan of the vessel.

4: Can pressure vessels be customized for specific industrial applications?

Yes, pressure vessels can be highly customized to meet specific industrial applications. Customization can include size and shape modifications, the addition of specific liners or coatings for chemical resistance, the integration of unique inlet and outlet configurations, and the inclusion of specialized monitoring and control systems. Customization ensures that the vessel meets the unique operational requirements of different industries, such as chemical processing, oil and gas, or biogas production.

5: What role does technology play in modern pressure vessel manufacturing?

Technology plays a significant role in modern pressure vessel manufacturing. Advanced software for design and simulation allows for more precise and efficient vessel designs. Automated welding techniques improve fabrication quality and consistency. Non-destructive testing technologies, such as ultrasonic and radiographic testing, provide thorough and reliable inspection results. Additionally, real-time monitoring systems can be integrated into vessels for ongoing operational data, enhancing safety and efficiency.

Related Blog Post

Pressure Vessel Design & Engineering: Concept to Launch

What is Pressure Vessel Design and Engineering: Code-Ready Guide

What are the Key Factors in Pressure Vessel Engineering

How Do You Design a Pressure Vessel: A Step-By-Step Guide

What is Pressure Vessel Fabrication and Manufacturing

About Author